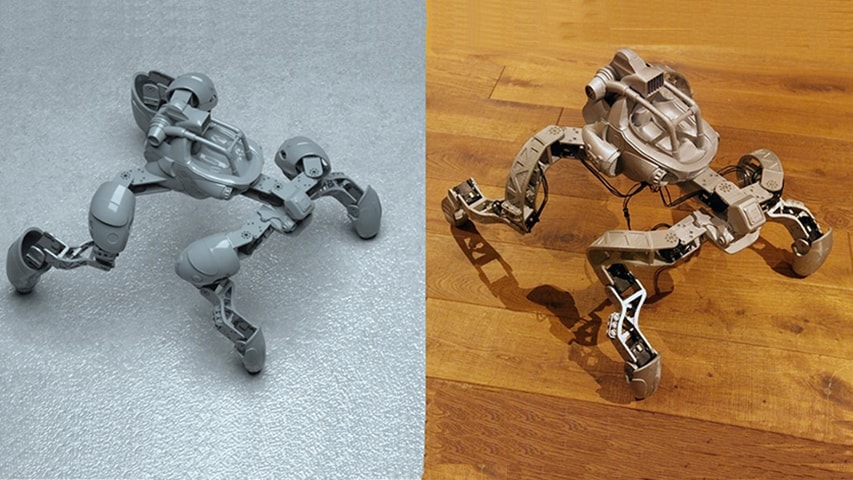

[Image above] Digital designs for robotic creatures are shown on the left, and physical prototypes produced via 3-D printing are on the right. Credit: Carnegie Mellon University

Seems like robots are trending in the news lately.

Just last week we reported on how sisters Lavanya and Melissa Jawaharlal, both mechanical engineers, cofounded STEM Center USA—an organization in Claremont, Calif., that runs a program using robotics and other hands-on creative methods to teach science, technology, engineering, and math to students. The pair just secured a $200,000 deal from ABC’s investment reality television show “Shark Tank” that they’ll use to take their revolutionary STEM robotics education concept nationwide.

And ten-year-old Kaiya Hollister and nine-year-old Jensie Coonradt from suburban Chicago also made headlines for competing in the World Robot Olympiad International Championship in Doha, Qatar, on November 6 with the robot they designed, built, and programmed.

Most of us can agree robots of all levels are fascinating and totally deserve the hype. But few of us have the knowledge and/or capability to actually design these sophisticated machines from scratch.

At least that used to be the case.

Disney Research and Carnegie Mellon University have developed a new tool that can help anyone—even non-engineers—“design and build a customized walking robot using a 3-D printer and off-the-shelf servo motors,” according to a recent CMU news release.

“Progress in rapid manufacturing technology is making it easier and easier to build customized robots, but designing a functioning robot remains a difficult challenge that requires an experienced engineer,” Markus Gross, vice president of research for Disney Research, says in the release. “Our new design system can bridge this gap and should be of great interest to technology enthusiasts and the maker community at large.”

The system includes intuitive editing tools that allow the user to indicate key robotic elements—like shape, size, and number of legs of the robot—and also has the built-in capability to test whether or not the proposed design will operate as envisioned or if any tweaks are needed before parts are printed. When the design is complete, the system generates 3-D geometry for all parts needed for assembly that can be sent to a 3-D printer for fabrication.

While it only takes minutes to design these robotic prototypes using this new system, printing and assembly still require major time and financial commitments.

“It took us minutes to design these creatures, but hours to assemble them and days to produce parts on 3-D printers,” Bernhard Thomaszewski, a research scientist at Disney Research, says in the release. “The fact is that it is both expensive and time-consuming to build a prototype—which underscores the importance of a design system such as ours, which produces a final design without the need for building multiple physical iterations.”

The research team presented the system at SIGGRAPH Asia 2015, the ACM Conference on Computer Graphics and Interactive Techniques, in Kobe, Japan.

Check out the video from Disney Research that presents the interactive robot design system in action!

Credit: DisneyResearchHub; YouTube

Author

Stephanie Liverani

CTT Categories

- Basic Science

- Education

- Electronics

- Manufacturing