[Image above] Credit: Critical Materials Institute; YouTube

Many technologies today rely on components that include rare-earth elements. Rare-earth elements are 17 elements in the periodic table—15 lanthanides plus scandium and yttrium—that have unique properties that offer better performance, less energy consumption, and other enhancements to electronics and communications devices. Rare earths also are used in the medical and defense industries, among others.

And although they’re not really rare, only eight countries are currently mining and producing rare earths—with China as the dominant producer. The last North American mine, U.S.-based Molycorp, which went bankrupt in 2015, was sold this past summer, leaving the U.S. without a domestic supplier of rare earths.

Earlier this year, the CEO of American Elements encouraged the government to take over the Molycorp mine through eminent domain to resurrect rare earth production in the U.S. But it’s unclear whether or not the U.S. could eventually compete commercially with lower-cost imports.

However, a new project funded by the U.S. Department of Energy could be a shot in the arm for domestic rare earth production and the coal industry. It has identified nine projects that will receive nearly $4 million in cost-shared federal funding to “improve the technical, environmental, and economic performance of new and existing technologies that extract, separate, and recover rare-earth elements from domestic U.S. coal and coal by-products,” according to a DOE news release. The National Energy Technology Laboratory will oversee and manage the REE projects.

One of those projects is getting nearly $875,000 to convert coal fly ash to rare-earth oxides. In a collaboration between Battelle and Rare Earth Salts (RES), researchers will use proprietary processes to separate rare-earth elements from coal fly ash and then purify them to make a marketable product, according to a Battelle news release.

“This is an important project to prove the viability of this approach,” Battelle research scientist Rick Peterson explains in the release. “The need to recover rare-earth elements in the United States is of national importance, since so much of the capacity to produce these critical materials lies outside the U.S.”

Coal fly ash is a by-product of coal combustion in coal-fired power plants that generate electricity. Because of its strength and environmental advantages, it has been used in place of cement to make concrete, and as a filler in multiple applications.

Battelle’s acid digestion process extracts rare earths from coal fly ash while recycling the chemicals used in the process. RES also uses an environmentally friendly process to separate and purify rare earth elements.

“We are particularly interested in recovering and purifying the magnetic rare-earth elements (such as praseodymium, neodymium, and dysprosium), but we’ll be doing work in recovery of all the naturally occurring rare-earth elements plus yttrium and scandium,” Peterson writes in an email.

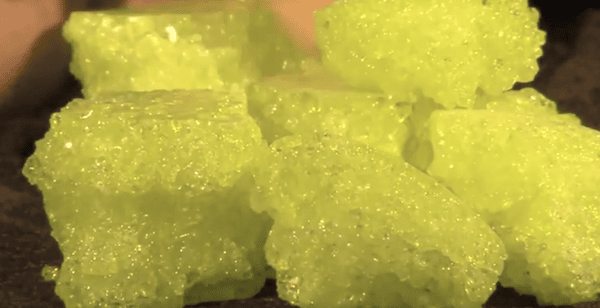

Yttrium sample. Credit: Museum für Naturkunde Berlin, Y_Yttrium_By Alchemist-hp_Wikimedia Commons; Flickr CC BY-NC-ND 2.0

With demand for coal declining due to industry regulations, the DOE projects could also benefit the coal industry. “Our technology positions us to be a primary producer of consistent, low-cost, rare-earth oxides to Western economies,” RES CEO Cameron Davies says in the release. “As we seek additional sources of domestic rare earth feedstock, coal fly ash presents a promising opportunity.”

Peterson explains that coal-based sources have a higher proportion of heavy rare-earth elements, which tend to be more scarce, making them more valuable than light rare earths.

“This project is important to ensure that we have an accessible and recoverable supply of all the rare-earth elements, which are vital to industries from ceramics to energy, electronics, and defense,” he writes.

Revitalizing the coal industry and lessening U.S. dependence on rare earth imports might be considered two positive “by-products” of the DOE’s rare-earth element projects.

To learn more about the projects, read the announcement here.

Did you find this article interesting? Subscribe to the Ceramic Tech Today newsletter to continue to read more articles about the latest news in the ceramic and glass industry! Visit this link to get started.

Author

Faye Oney

CTT Categories

- Electronics

- Energy

- Environment

- Manufacturing

- Market Insights