[Image above] Credit: FOTO Eak, Shutterstock

I recently celebrated my one-year anniversary as an aerial arts instructor, and one thing that’s become abundantly clear to me while working with students is the need to balance strength training with active flexibility.

From the very first class, students quickly discover that a lot of strength is needed to climb into the lyra (hoop) or silks. So, they initially focus on building muscle. But a deceptive amount of flexibility is required after getting on the apparatus to achieve the pretty poses seen on social media, which more seasoned students appreciate and incorporate into their training.

This differing balance in physical capabilities between new and experienced aerial students can be related to the differing properties of ceramics and metals. Ceramics, like the new students, excel at withstanding forces that push or squeeze them together (high compressive strength). On the other hand, they tend to break when subjected to pulling forces or bending motions, meaning they have low tensile and flexural strength.

Metals, meanwhile, usually demonstrate a good balance between compressive, tensile, and flexural strength. So, this material—like the advanced students—can handle tasks that require both strength and flexibility.

Because high compressive strength is considered a given for ceramics, more attention has been focused on developing methods to directly measure or indirectly assess tensile strength. However, only focusing on the weak spots and taking the innately stronger properties for granted can lead to a misunderstanding of the material’s—and athlete’s—capabilities and what stressors they can truly handle.

In a recent paper, researchers from the DEVCOM Army Research Laboratory led by ACerS Fellow Jeffrey Swab addressed this oversight in the corpus of ceramic testing methods and revealed “the most appropriate and only specimen geometry that should be used to generate compression strength values for ceramics.”

The authors begin by describing the different failure mechanisms of ceramics when subjected to either tensile or compressive loads. While tensile strength is controlled by the single largest “flaw” exposed to the applied load, resulting in the formation of a macrocrack, compressive strength and the associated fracture process are controlled by the nucleation, growth, and coalescence of microcracks.

Of the five standards currently in place to determine the quasistatic uniaxial compressive strength of ceramics, most use cuboid or cylinder-shaped test specimens. These specimens tend to form macrocracks at their ends upon loading, which then propagate into the specimen and lead to premature fracture rather than “a true manifestation of the compressive failure process,” the authors write.

This issue of tensile failure during compression tests led investigators in the 1960s and 1970s to advocate for a different specimen geometry. One of the most promising alternatives to emerge was the dumbbell geometry. Compared to the cuboid and cylinder-shaped test specimens, an early study showed a consistent and repeatable strength value for dumbbell-shaped test specimens across a range of ceramics.

Despite the success of this study, and the subsequent establishment of ASTM C1424, few other studies or standards have used dumbbell-shaped test specimens. So, the authors of the recent paper summarized the few studies that used this geometry and then reported on their own experiments using the dumbbell shape.

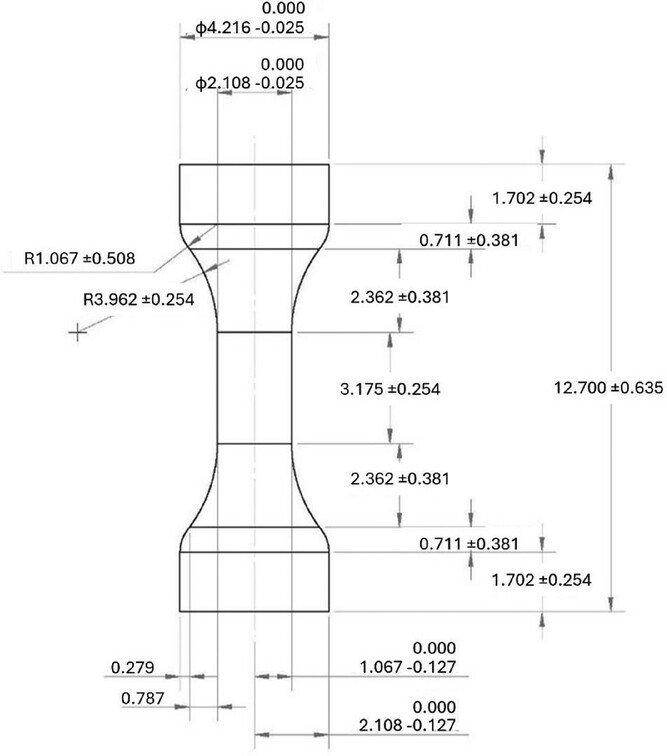

The dumbbell geometry used for specimens in the recent study. It is a scaled-down version of the specimen developed by Dunlay, Tracy, and Perrone (1989). All dimensions are in millimeters. Credit: Swab et al., Journal of the American Ceramic Society

Compressive strength data for a wide variety of advanced ceramics and two float glasses (soda-lime silicate and borosilicate) were generated for strain rates between 10−4/s and 102/s. Compared to previously reported strength data based on cuboid and cylinder-shaped test specimens, the values obtained with the dumbbell-shaped test specimens consistently yielded higher strength values with lower scatter. Additionally, the issue of macrocracks forming at the specimen’s ends was essentially eliminated.

“Based on the extensive data generated in this effort on a wide range of ceramics, it can definitively be stated that cuboids and cylinders should not be used to determine compression strength values for these brittle materials,” the authors conclude. “The only appropriate means of generating representative and ‘true’ compression strength values for advanced ceramics at strain rates between 10−4/s and 102/s is by using a dumbbell-shaped specimen.”

Be it in the laboratory or the gym, this study shows that both researchers and my students can benefit from using dumbbells to round out their testing or training regime.

The paper, published in Journal of the American Ceramic Society, is “Compression strength of advanced ceramics: An overview and data summary” (DOI: 10.1111/jace.70099).

Author

Lisa McDonald

CTT Categories

- Basic Science

Related Posts

Sports-quality ice: From pond side to precision Olympic engineering

February 12, 2026