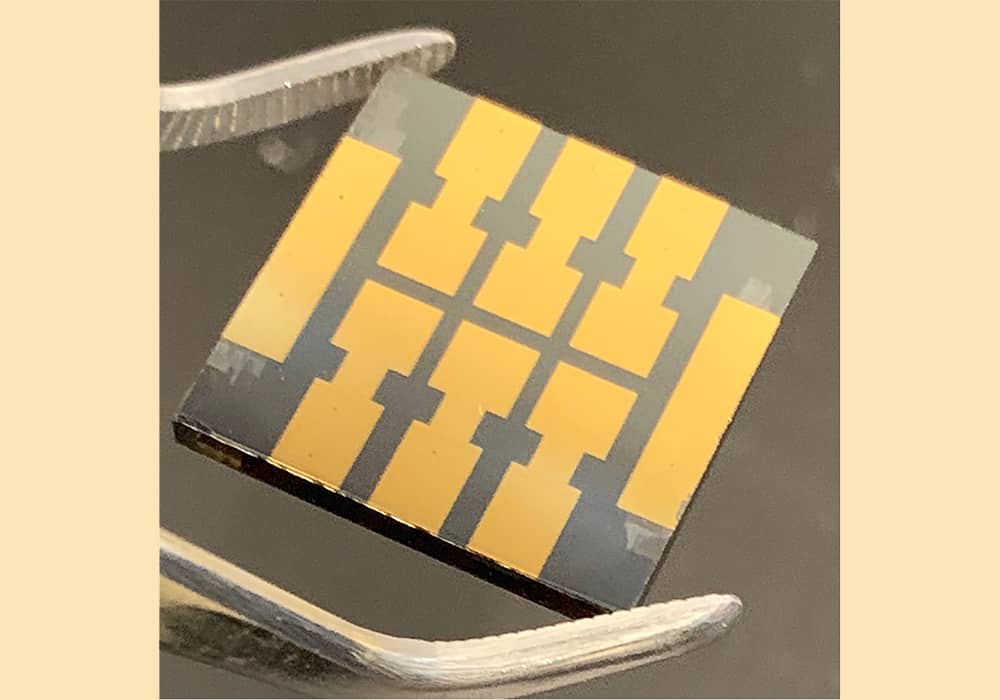

[Image above] Brown University researchers used self-assembled monolayers to toughen interfaces in perovskite solar cells, a process that made the cells more efficient, stable, and reliable. Credit: Padture Lab, Brown University

The virtual Materials Challenges in Alternative and Renewable Energy (MCARE 2021) conference is gearing up for this July, and one topic sure to receive extensive coverage is perovskites.

The term “perovskite” traditionally refers to a specific mineral—calcium titanium oxide—but the term also applies to the class of halide compounds that have the same type of crystal structure as CaTiO3.

Many energy researchers are investigating use of perovskite materials in next-generation solar cells due to their efficiency, cost, and versatility compared to traditional silicon cells. The challenge with perovskites, however, is their durability—particularly their “love–hate” relationship with the sun. Light from the sun is needed to generate electricity, yet exposing perovskites to the sun’s rays causes the material to degrade.

Improving the mechanical properties of perovskites is vital to commercializing this solar cell technology. Nitin Padture, the Otis E. Randall University Professor and Director of the Institute for Molecular and Nanoscale Innovation at Brown University, is one researcher working on this challenge.

Padture, an ACerS Fellow, has studied perovskites for solar cell applications since moving to Brown University in 2012. Last year his group published a paper on healing cracks in perovskite films after they appear, but a new study published by them in Science this month looks to prevent cracks before they occur.

In the paper, they explain that several internal and external mechanical stresses can cause perovskite solar cells to fracture. One cause for internal stress is that solar cells are made up of several layers, each having a different coefficient of thermal expansion (CTE). When the temperature changes, the layers expand and contract by differing amounts, which can lead to stress and decoupling at the layer interfaces—and a significant drop in the cell’s power conversion efficiency.

The weakest interface is the one between the perovskite film used to absorb light and the electron transport layer, which keeps current flowing through the cell. Because a “chain is only as strong as its weakest link, … If we can strengthen that, then we can start making real improvements in reliability,” Padture says in a Brown press release.

To strengthen this interface, Padture and his group began experimenting with a special type of compound called self-assembled monolayers (SAMs). “When you deposit [SAMs] on a surface, the molecules assemble themselves in a single layer and stand up like short hairs. By using the right formulation, you can form strong bonds between these compounds and all kinds of different surfaces,” Padture says.

In an email, Padture says he previously worked with SAMs in a different context, as ceramic nanowires for gas sensors. His unique background in both mechanics and solar cells, though, allowed him to put “two and two together” and apply SAMs to solar cells as well.

They chose to use an iodine-terminated trialkoxysilane SAM as the “glue” between a metal halide perovskite thin film and the underlying tin oxide electron transport layer. They chose this SAM for several reasons:

- Trialkoxysilane SAMs are known to self-assemble and cross-link readily on certain oxide surfaces, such as the tin oxide they chose for the electron transport layer.

- The “brush-like” morphology of this SAM is expected to form electrostatic bonds to the metal halide perovskite thin film.

- The short length of the alkyl chain in the SAM makes the SAM-coated surface sufficiently lyophilic, i.e., readily dispersed by a solvent, and thus easily deposited on the thin film.

- SAMs in general, and trialkoxysilane-based SAMs in particular, increase power conversion efficiency and reduce hysteresis in perovskite solar cells.

They created the solar cells in three steps: 1) depositing the tin oxide electron transport layer on indium tin oxide-coated glass substrates, 2) depositing the SAM on the electron transport layer by dip-coating at room temperature, and 3) depositing the metal halide perovskite thin film on the SAM through a variation of the solvent-engineering method. They also created cells without SAM for comparison.

The solar cells treated with iodine-terminated SAM demonstrated a dramatically increased functional life compared to cells without SAM. Specifically, while the cells without SAM retained 80% of their peak efficiency for around 700 hours, the SAM cells remained strong after 1,300 hours of testing and were projected to retain 80% for about 4,000 hours.

In the Brown press release, first author and doctoral student Zhenghong Dai says they took the unconventional step of breaking the cells open after testing to better understand the reason for this durability. “In the control cells without the SAMs, we saw all kinds of damage such as voids and cracks. But with the SAMs, the toughened interfaces looked really good. It was a dramatic improvement that really kind of shocked us,” he says.

In addition to increased functional life, SAM cells demonstrated increased power conversion efficiency, from 20.2% to 21.4%, due to the SAM eliminating tiny molecular defects that form when the two layers bond. Padture says this finding was a “nice surprise” because it meant they could improve reliability without losing efficiency. Plus, because SAMs are made from readily available compounds and are easily applied, addition of SAMs would likely add little to the production cost if the technique is commercialized.

Padture’s research group plans to expand on this research using a $1.5 million grant they won from the U.S. Department of Energy’s Solar Energy Technologies Office Fiscal Year 2020 Perovskite Funding Program. They will use the SAM technique to fortify not only other interfaces in the solar cell but the material layers themselves.

The paper, published in Science, is “Interfacial toughening with self-assembled monolayers enhances perovskite solar cell reliability” (DOI: 10.1126/science.abf5602). Free access to the full article is available here.

Author

Lisa McDonald

CTT Categories

- Energy

Related Posts

‘Fairy circles’ may help mark natural underground hydrogen deposits

September 18, 2025