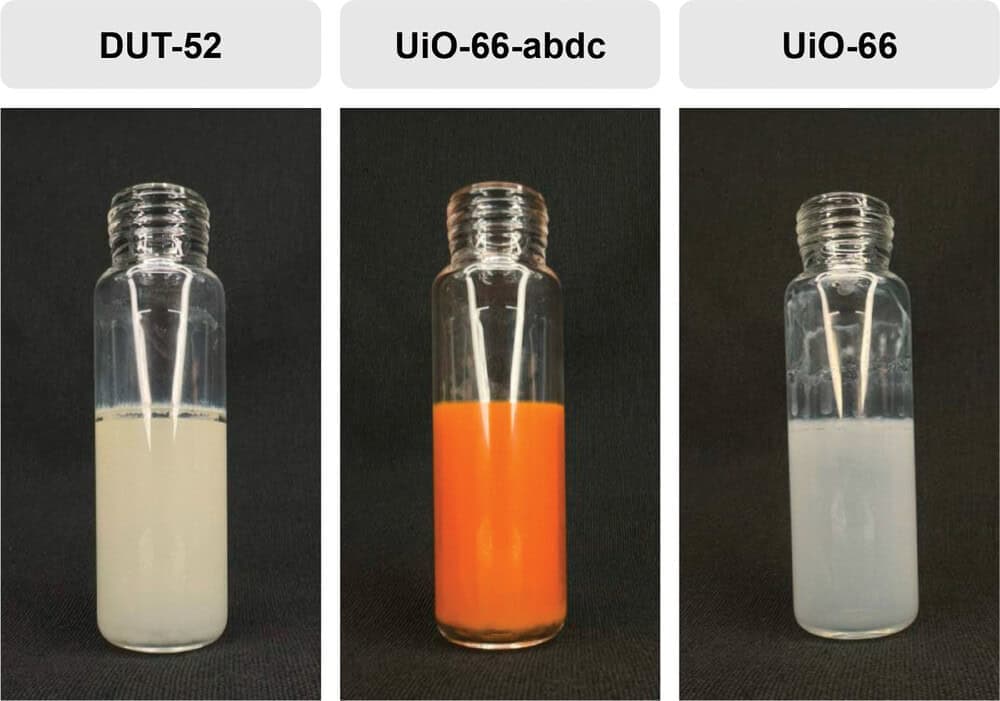

[Image above] Example of MOF-coated glass vials developed by researchers at the University of La Laguna in Spain. Credit: Taima-Mancera et al., Advanced Functional Materials (CC BY 4.0)

Access to water and sanitation are recognized by the United Nations as human rights, and the new national drinking water standards established by the U.S. Environmental Protection Agency will make this right available to millions of more people. Realizing the objectives of these standards, however, will require states to upgrade their water treatment plants to successfully test and remove the regulated chemicals from the water.

Metal-organic frameworks (MOFs) are an emerging material system for water treatment applications. These porous hybrid materials consist of metal ions or clusters interconnected by organic “linker” molecules to form highly ordered hollow structures. This structure gives MOFs a surprisingly large internal surface area, which makes the material desirable for storage, separation, and catalysis applications.

Synthesizing MOFs in bulk, however, is challenging. These materials have less robust thermal and mechanical properties than ceramics, so they do not hold up well during traditional processing techniques, thus limiting their adoption in commercial applications.

Researchers have proposed various methods for stabilizing MOFs, such as turning the structure into glass or supporting the structure with nanopillars. In an open-access paper published last month, researchers from the University of La Laguna in Spain demonstrated another way to fabricate MOFs that not only stabilizes the material but also integrates it directly into practical devices.

In the new method, MOFs are grown directly onto the inner walls of ordinary glass vials. This process allows the vial to double as both the sample container and extraction device for testing water contaminants.

Previous studies attempting to grow MOF coatings inside glass vials were unsuccessful because they relied on conventional polymer linkers that degraded when exposed to common organic solvents. In contrast, the new method uses carboxylate anchoring points rather than polymeric binders to encourage growth of MOF crystallites. This approach results in a thin MOF coating that does not degrade when exposed to different solvents.

The researchers tested their technique using three zirconium-based MOFs known for their stability and tunable pore structures. The MOF coatings successfully extracted trace contaminants from water stored in the vial, with the best result being 90% of contaminants captured in just one hour. After capture, the contaminants could be released from the MOFs in mere minutes using a simple solvent wash, allowing the preconcentrated substances to be easily analyzed.

Rigorous shaking of the vial is typically needed to encourage extraction, but the researchers showed the MOF coating captured contaminants even with only mild or no agitation. In addition, performing the extraction and desorption process dozens of times did not significantly affect the coating’s extraction efficiency, thus demonstrating the device’s robustness and reusability.

“These MOF-coated vials open a plethora of possibilities, spanning from automation to on-site analytical sample preparation while assuring highly processable devices,” the researchers write.

Even with only mild or no agitation, the MOF coating still extracted contaminants from the water. The experiments were performed in triplicate and conducted under the same experimental conditions (18 mL of aqueous standard at 20 µg L−1). Credit: Taima-Mancera et al., Advanced Functional Materials (CC BY 4.0)

In a press release, the researchers say they plan to develop MOF coatings optimized for additional contaminant types and to explore integrating the vials with portable testing systems for on-site analysis.

The open-access paper, published in Advanced Functional Materials, is “Metal–organic framework-coated glass vials: A step forward in analytical platforms” (DOI: 10.1002/adfm.202402517).

Author

Lisa McDonald

CTT Categories

- Environment

- Material Innovations