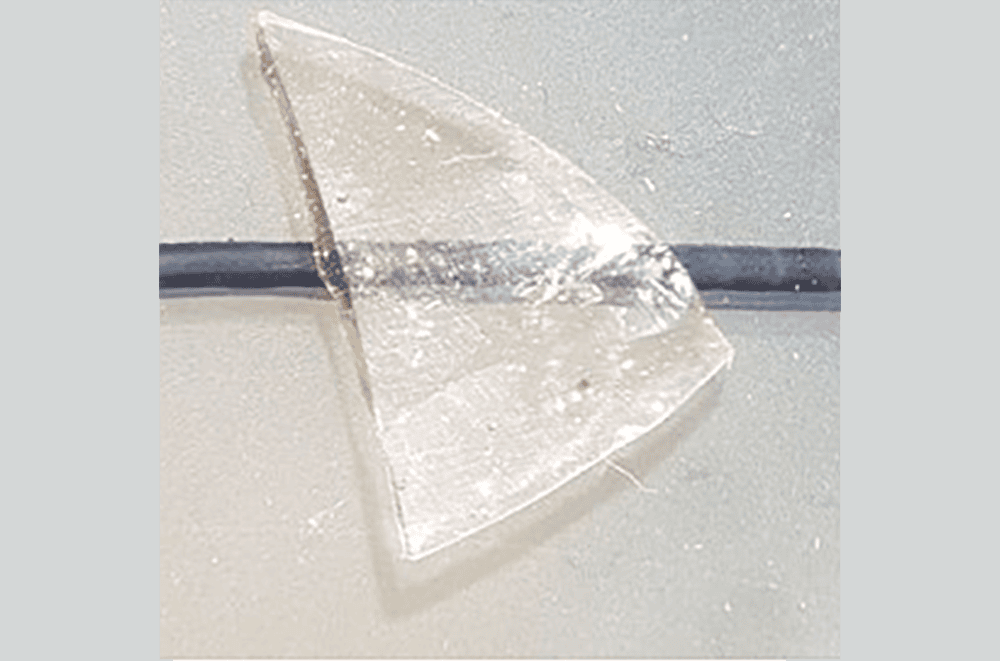

[Image above] A sample of the metal-organic framework glass ZIF-62. Credit: Morten Smedskjaer and Yuanzheng Yue

If you are a longtime reader of Ceramic Tech Today, you likely are familiar with the materials known as metal-organic frameworks (MOFs).

MOFs are porous hybrid materials that consist of a highly ordered 3D array of positively charged metal ions surrounded by organic “linker” molecules. The material’s hollow structure gives it a surprisingly large internal surface area, which makes it desirable for storage, separation, and catalysis applications.

Though MOFs have immense potential in various applications, MOFs face a significant challenge to large-scale production—they are difficult to synthesize in bulk.

“MOFs are vulnerable with respect to stability compared to the competing materials. For instance, due to the relatively weak metal–ligand coordination bonds, many MOFs are chemically unstable and have low endurance in different types of chemicals environments, e.g., acidic or basic environment,” an ACS Central Science article explains.

Thus, finding new ways to synthesize MOFs so that they are stable in bulk form is an important area of study for researchers.

We’ve covered some MOF manufacturing advances on CTT, such as here and here. But one manufacturing technique in particular stands out—the formation of MOF in a glassy phase.

In 2015, Aalborg University professor Yuanzheng Yue observed the first calorimetric glass transition of MOFs. “That was an exciting finding in terms of both fundamental science and technological application,” he says in an email. Due to the glass stability, “the discovery made it possible to make bulk materials from MOFs, or to manufacture MOF glasses having a variety of shapes and sizes.”

A team of researchers from Europe, China, and Japan, including Yue, published the first paper on MOF glasses in Nature Communications. They focused specifically on a subset of MOFs called zeolitic imidazolate frameworks (ZIFs), which exhibit higher thermal and chemical stability than other MOF subsets.

They succeeded in manufacturing bulk ZIF glasses by melt-quenching, showing “that the wide-ranging melting temperatures of zeolitic MOFs are related to their network topologies and opens up the possibility of ‘melt-casting’ MOF glasses.”

Since the 2015 study, researchers have conducted many more studies on ZIF glasses, looking to improve the manufacturing technique and to understand the structure and properties of these materials. This year, two new studies led by Yue and fellow Aalborg professor Morten Smedskjaer dive into the mechanical properties of ZIF glasses.

ZIF glasses: Indentation behavior and fracture toughness

Indentation and deformation behavior

The first study, published in Proceedings of the National Academy of Sciences, was done at Aalborg University. They investigated the indentation and deformation behavior of ZIF glasses, specifically ZIF-62.

“We chose ZIF-62 glass because it can be made in relatively large, homogeneous bulk samples for mechanical testing, and also because it has already been studied regarding its structure and various material properties,” they explain. In particular, ZIF-62 has an ultrahigh glass-forming ability and exhibits higher thermal and structural stability in the liquid state compared to other ZIFs.

In addition to these properties, ZIF-62 made a perfect case study for investigating fracture and deformation behavior because of a previous anomalous result found concerning this behavior.

“Usually, glasses with a higher Poisson’s ratio exhibit higher ductility than those with a lower ratio. However, the ZIF glass displays an anomalous behavior; that is, it features easy crack nucleation despite its high Poisson’s ratio,” the researchers explain. The reason for this anomalous behavior is what they explored in the study.

The researchers performed microindentation and nanoindentation tests on the ZIF-62 glass and made several interesting observations.

First, in terms of crack patterns, they observed both median and radial cracks, a pattern seen in many oxide glasses as well. However, “the occurrence of the median crack in ZIF glass is an abnormal behavior, since it is a high Poisson’s ratio system.” They suggest this cracking could be related to the coordinative zinc-nitrogen bonds in ZIF glasses, which are weaker than the ionic, covalent, and metallic bonds in other families of glasses.

Second, the researchers discovered the formation of shear bands in the glass under indentation. A shear band is a narrow zone of intense shearing strain, usually of plastic nature, that develops during severe deformation of materials.

They explain that shear band formation has not been found in any other fully polymerized 3D network glasses. Though similar shear bands have been observed in some chalcogenide glasses, “the microscopic origin of the shear band formation in the present ZIF glass is distinct,” they say. In particular, they attribute the formation in part to breakage of the weaker coordinative bonds in ZIF glasses (the same aspect which caused median crack patterns, as mentioned above).

In the conclusion, they note that, in addition to the study revealing the impact of bonding features and microstructure of a glass on its mechanical properties, the results are “beneficial for assessing the overall mechanical performances of MOF bulk glasses in order to find their application fields” and to understand the source of the glass brittleness in general.

The paper, published in Proceedings of the National Academy of Sciences, is “Observation of indentation-induced shear bands in a metal−organic framework glass” (DOI: 10.1073/pnas.2000916117).

Fracture toughness

The second study, published in Nature Communications, was done in collaboration with a researcher from the University of California, Los Angeles. This study also focused on ZIF-62 glass, but instead of looking at its indentation cracking patterns, the researchers looked at its fracture toughness.

Fracture toughness is a property which describes the ability of a material containing a crack to resist fracture. It is a very important property in materials design because, while the occurrence of flaws is not completely avoidable in fabrication, a material with high fracture toughness can prevent those flaws from growing out of control.

Unlike other studies on MOF glass mechanical properties, the researchers did not use indentation testing to investigate the fracture toughness. Instead, they used a single-edge pre-cracked beam method and reactive force field-based molecular dynamics simulations.

Both the experiment and simulation found low values for fracture toughness (0.104 MPa m0.5 and 0.097 MPa m0.5) and fracture surface energy (0.82 Jm−2 and 0.98 Jm−2). The researchers again attribute these findings to the breaking of weak coordinative bonds, as they did for numerous observations in the first study.

They calculated several other property values as well, including strength and modulus of elasticity (Young’s modulus). And when viewed collectively, the properties give ZIF-62 glass a “uniqueness in its fracture behavior,” they say.

“First, it features pronounced nanoductility compared to other glasses, e.g., silica, but yet it exhibits very low fracture toughness on the macroscale, similarly to that of elastomers or high-toughness foams. Moreover, with this low toughness, the ZIF-62 glass possesses a much larger Young’s modulus (E = 4–6 GPa) than foams and elastomers (E < 1 GPa),” they explain.

Ultimately, “These characteristics positions the MOF glass in a hitherto unoccupied region of the Ashby KIc vs. E plot,” they state.

In the conclusion, the researchers say the results have a “far-reaching implication” for understanding fracture behavior and mechanical properties in other MOF glasses as well. The results are also important for finding the solutions to overcome the brittleness of MOF glasses.

The open-access paper, published in Nature Communications, is “Fracture toughness of a metal-organic framework glass” (DOI: 10.1038/s41467-020-16382-7).

Ashby plot of the relation between fracture toughness (KIc) and Young’s modulus (E) for a range of materials. ZIF-62 glass occupies a previously unoccupied region of the plot. Credit: To et al., Nature Communications (CC BY 4.0)

In an email, Smedskjaer says they would like to study the indentation behavior and fracture toughness of other MOF glasses. “However, in most cases, the samples are currently too small to allow for mechanical testing,” he says.

Regardless, Smedskjaer looks forward to investigating MOF glasses in other ways as well. “In recent studies, a high degree of structural disorder even at short length scales has been found, as well as an abnormal higher thermal conductivity of MOF glass relative to crystal. As such, there are likely many interesting phenomena waiting to be explored in this new glass family,” he says.

Author

Lisa McDonald

CTT Categories

- Basic Science

- Glass