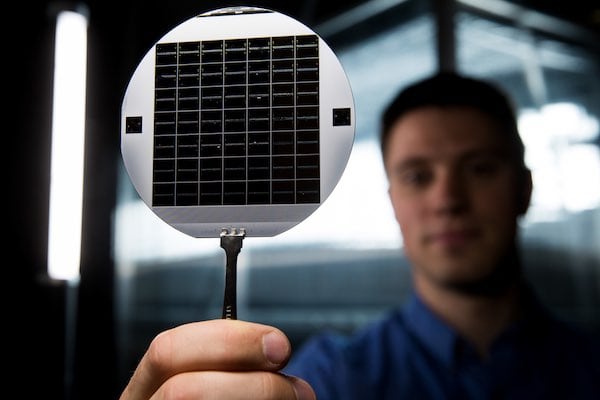

[Image above] Brigham Young University graduate student John Stout holds a flexible glass lab-on-a-chip device. Credit: Jaren Wilkey; BYU Photo

You know, medical diagnostics have come a long way.

But—in an age where driverless cars, robots that can read your mind, and Star Wars-esque holograms are reality—shouldn’t some of those diagnostics be, well, better?

Think about most standard laboratory blood tests—they usually require you to part with several vials of your blood, can take weeks to provide results, and can come with a pretty hefty price tag.

Instead, imagine a blood test that could deliver results almost instantly, at a fraction of the cost, and with only a few drops of your precious blood.

Sure—it sounds a lot like what biomedical startup Theranos promised consumers over the past few years. And it turns out that those claims were bogus.

But that doesn’t mean that such diagnostics are out of reach. In fact, some such tests are already fully within grasp. They’re called lab-on-a-chip—tiny devices that shrink the components of a full laboratory down to a tiny scale. And they’re incredibly valuable because lab-on-a-chip devices reduce the equipment, consumables, resources, sample quantity, and personnel required for laboratory-based diagnostic tests.

“With a lab-on-a-chip you can do a quick diagnostic test and get information right there, which is very useful when somebody’s got a disease that’s got a very short timeline to be treated,” says Mark Morrison, CEO of the Institute of Nanotechnology in Stirling, U.K., in an article on The Guardian. “What it effectively does is miniaturizes and compacts all the different processes that a researcher or a technician in the diagnostic lab uses.”

And with the help of some new research, more of these types of rapid medical diagnostics might soon become reality by incorporating one of our favorite materials—glass.

Researchers at Brigham Young University have devised a technique that incorporates glass to build tiny lab-on-a-chip devices, or flexible glass nanoelectromechanical systems (NEMS).

And although current lab-on-a-chip devices function on the microscale, these new devices shrink the scale even further—to the nanoscale. Such a small operating scale means that they open up the possibility to work with even smaller diagnostic units, such as individual proteins, viruses, and DNA.

Using common manufacturing processes (translation: good potential for scaling up to commercial quantities while keeping costs low), the researchers fabricated thin and flexible glass chips, layer by layer.

Starting with a thermal oxide base layer grown on a silicon substrate, they built microfluidic channels and then coated those channels with layers of silicon dioxide, adding thin metal electrodes on top to complete the chips.

Credit: Jaren Wilkey; BYU Photo

Credit: Jaren Wilkey; BYU Photo

But why glass you ask?

The wonder material offers structural support and yet is also inert, nontoxic, and easy to clean (i.e., stuff doesn’t stick to it very well).

“Glass is clean for sensitive types of samples, like blood samples,” graduate student and lead author John Stout says in a a BYU press release. “Working with this glass device will allow us to look at particles of any size and at any given range. It will also allow us to analyze the particles in the sample without modifying them.”

Although they’re made with glass, that doesn’t mean the chips are brittle. Designing the channels and the thickness of the glass layer with the right proportions allowed the researchers to create chips that bend and flex without breaking.

“If you keep the movements to the nanoscale, glass can still snap back into shape,” BYU electrical engineering professor and senior author Aaron Hawkins says in the release. “We’ve created glass membranes that can move up and down and bend. They are the first building blocks of a whole new plumbing system that could move very small volumes of liquid around.”

The promise of lab-on-a-chip devices is that they offer quick diagnostics, on site, at low cost. In addition to efficiency, however, they also can extend diagnostics to areas where full laboratory testing is impossible, such as in the field or in less-developed and resource-poor regions.

In addition, the flexible glass NEMS devices have potential applications beyond medical diagnostics, too—and could be used as diagnostic sensors for various other fields where detection of small amounts of particles is needed.

The paper, published in AIP Applied Physics Letters, is “Electrostatically actuated membranes made from silica thin films” (DOI: 10.1063/1.4975369).

Author

April Gocha

CTT Categories

- Glass

- Manufacturing

- Nanomaterials