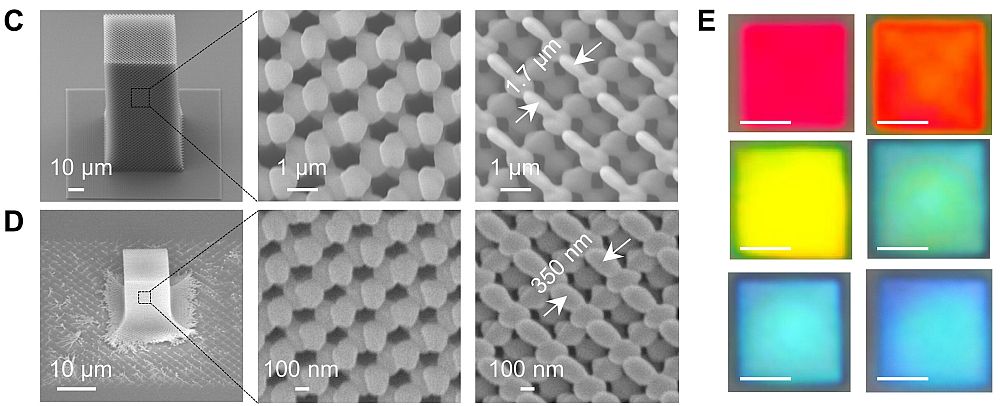

[Image above] Scanning electron microscope images of the as-printed (C) and sintered (D) glass photonic crystals. (E) Optical micrographs of the sintered glass photonic crystals with different feature sizes. Scale bars are 5 μm. Credit: Zhang et al., Science Advances (CC BY-NC 4.0)

Glass is an ideal material for many optical applications because of its high transparency, chemical and thermal stability, and mechanical properties. However, when it comes to manipulating light on the nanoscale, materials with a higher refractive index, such as gallium arsenide and silicon nitride, have typically been used instead.

Fortunately, advancements in nanofabrication techniques have opened the door to engineering glass structures on previously unimaginable scales. This expanded control over glass design can aid the development of nanoscale glass-based optical components.

Intricate glass shapes on the macroscale have been created using the 3D printing technique of stereolithography. This technique works by using light to solidify hybrid resins composed of silica nanoparticles and photocurable monomers.

Achieving microscale precision with conventional stereolithography is difficult, however. To achieve microscale structuring, two-photon polymerization uses a multi-photon laser rather than single photon source to achieve highly localized solidification of the hybrid resin.

Glass structures with submicrometer features have been printed using two-photon polymerization. However, fabricating glass structures with submicrometer features in all three dimensions remains a challenge.

Recently, a team of researchers from China, Denmark, and Singapore successfully fabricated glass structures with periodicities as small as 260 nm using two-photon polymerization. These structures, in addition to demonstrating an advancement in submicroscale glass processing, also exhibited breakthrough nanoscale light manipulation properties.

An organic–inorganic hybrid resin dubbed Glass-Nano, created by the authors, was the basis for this innovation. The resin contains an acryloxy-propyl polyoctahedral silsesquioxanes cage mixture as the silicon precursor. The multibranched acrylate groups in this mixture can be directly polymerized, dispersing the silicon elements throughout the polymer structure upon curing.

Two cross-linkers were also added to the resin: bisphenol A ethoxylate diacrylate, to increase the refractive index, and pentaerythritol triacrylate, to promote polymerization and enhance the mechanical properties of the printed structures. Toluene was used as a solvent to dissolve the polymerization initiator.

Two-photon polymerization of the resin resulted in glass photonic crystals with a low refractive index. The structures were then sintered in air at 650°C to remove all the organic components and convert the remaining material into silica glass.

The sintering temperature of 650°C was chosen because above 625°C, no further mass reduction was observed, indicating the complete removal of the organic components. The glass’s features shrunk slightly more up to 650°C, after which no further shrinkage occurred until 900°C.

Sintering resulted in an about 4.9-fold reduction per linear dimension and about 118-fold shrinkage in volume. This heat-induced shrinkage allowed for the submicroscale dimensions to be achieved while retaining high resolution of the printed structures.

Analysis of the glass structures using several spectroscopy and microscopy techniques confirmed

- The high purity of the sintered materials compared to standard glass,

- A uniform distribution of silicon and oxygen in the sintered structure, and

- The amorphous state of the sintered glass.

Optical testing of the 3D-printed glass photonic crystals showed that they exhibit nearly 100% reflectance in the visible spectrum, depending on the size of the features, which is much higher than the reflectance typically observed from similar structures in low–refractive index materials. Achieving such a high reflectance was possible thanks to both the large number of repeat units (>20) and extremely high degree of structural uniformity that this fabrication method and novel hybrid resin allow.

Numerical simulations of the glass structures also revealed that the “high-reflectance region coincided with a partial bandgap in the projected band structure, which inhibits light propagation in the photonic crystals across a wide range of incidence angles,” the authors write. “This partial bandgap is affected by the symmetry and geometry of the photonic crystal design.”

In a press release, first author Wang Zhang, research fellow at Singapore University of Technology and Design, notes that “Historically, low-index materials like silica were seen as optically weak for this purpose.”

“But our findings show that with enough uniformity and structural control, [low-index materials] can outperform expectations—and even rival high-index materials in reflectance,” he says.

Ultimately, the researchers conclude the paper by writing “These findings open opportunities for the development of high-performance optical devices using low-refractive index materials,” for instance, flexible optical sensors with improved signal strength and optical waveguides with better light confinement.

The open-access paper, published in Science Advances, is “Nanoscale 3D printing of glass photonic crystals with near-unity reflectance in the visible spectrum” (DOI: 10.1126/sciadv.adv0267).

Author

Laurel Sheppard

CTT Categories

- Glass

- Nanomaterials

- Optics