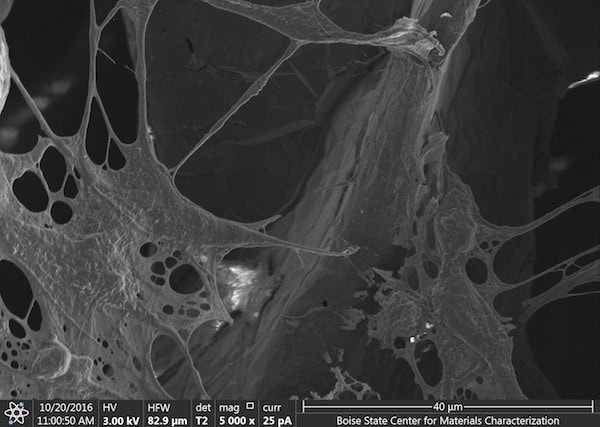

[Image above] Credit: David Estrada, Boise State University

Graphene in 3-D form has made several appearances in the news in the past couple of years. Last year Rice University researchers created graphene foam using powdered sugar and nickel powder.

Other researchers from Kansas State University broke a world record when they created graphene aerogel in a 3-D printer.

Another study found that a graphene foam composite displayed superior properties for deicing aircraft.

Now, with new research from scientists at Boise State University, graphene foam soon could play a crucial role in joint replacement and treatment of osteoarthritis pain.

Led by Ph.D. student in the Micron School of Materials Science and Engineering, Katie Yocham, and codirector of the Boise State University’s Advanced Nanomaterials and Manufacturing Laboratory, David Estrada, researchers mixed graphene foam with animal cells (ATDC5) to build “bioscaffolds,” to replace cartilage destroyed by osteoarthritis, according to a Boise State news release.

“If we could take graphene foam, adhere a patient’s own stem cells on it then and inject that into someone’s knee to regrow their own cartilage, that would be the ‘pie in the sky,’” Estrada says in the release.

Graphene foam is strong, flexible, and highly conductive, which makes it suitable for helping nerve cells transmit information, the researchers say. Graphene also drives stem cell production of biomolecules secreted by cells within connective tissue, according to a Newswise article.

“In tissue engineering, graphene represents a unique material with structure property processing correlations that can be used to design bioscaffolds to communicate electrically and mechanically with adhered stem cells, driving their differentiation down various pathways,” Estrada adds in the article.

The researchers plan to continue to investigate various types of graphene and their impact on stem cell fate, Estrada writes in an email and says that chemical exfoliation is one area they plan to study. “Graphene can be synthesized by chemical exfoliation, via chemical vapor deposition, and sublimation of Si from SiC surfaces,” he explains. “This results in very different structure–property–processing correlations and our preliminary data shows this has a significant impact on the performance of graphene as a bioscaffold.”

Estrada and a colleague have already formed a company to commercialize some of their research conducted at the Advanced Nanomaterials and Manufacturing Laboratory at the university.

This work builds on previous research where Estrada and a team previously demonstrated using graphene foam as a scaffold for growing muscle tissue to regenerate tissues and organs for human implants.

In addition to treating arthritis, their research could be used in the military in combat to treat musculoskeletal injuries.

According to the Centers for Disease Control and Prevention, an estimated 54.4 million adults in the U.S. suffer from arthritis. Over 30 million U.S. adults have been diagnosed with osteoarthritis, the most common form. And the numbers will only increase as the population ages.

Sounds like Estrada’s and Yocham’s research could not have come at a better time.

The paper, published in Advanced Engineering Materials, is “Mechanical Properties of Graphene Foam and Graphene Foam—Tissue Composites” (DOI: 10.1002/adem.201800166).

Want to read more articles like this? Subscribe to the Ceramic Tech Today newsletter to continue to receive the latest news in the ceramic and glass industry right in your inbox! Visit this link to get started.

Author

Faye Oney

CTT Categories

- Basic Science

- Biomaterials & Medical

- Material Innovations

- Nanomaterials