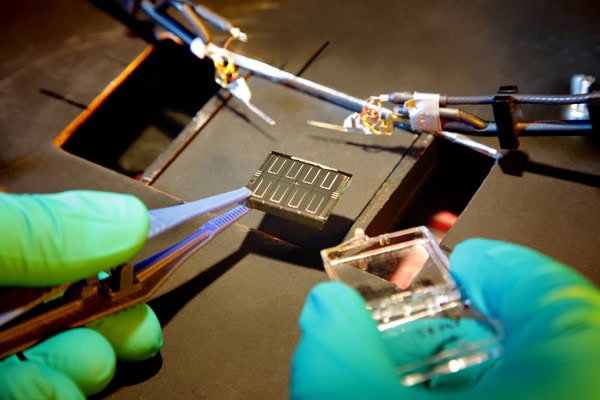

[Image above] Researchers from the University of Luxembourg and TDK have developed a highly conductive oxide film that will help solar cells harness more of the sun’s energy. Credit: Susanne Siebentritt; University of Luxembourg

Progress is sometimes slow, often painful, but almost always worth it.

Likewise, advancements in photovoltaic research, though often slow and painful, will eventually pay off, leading to LEDs, touch screens, and solar cells that absorb more sunlight and are more efficient.

Researchers from the University of Luxembourg and Japanese electronics company TDK report that such progress is being made and that they’ve developed a highly conductive oxide film that will help solar cells harness more of the sun’s energy.

Their undoped zinc oxide film boasts increased infrared transparency and creates a higher current that could make for those more efficient devices.

According to a university news release, their findings, published in Progress in Photovoltaics, represent the first time these films were prepared in a one-step process and are stable in air.

“The films made at the University of Luxembourg have been exposed to air for one and half years and are still as conductive as when they were fresh prepared,” says Susanne Siebentritt, professor and head of the photovoltaics lab at the University of Luxembourg, in the release. “It is a fantastic result, not only for solar cells, but also for a range of other technologies.”

In previous attempts to create a more conductive solar film, impurities—such as aluminum and its free electrons—were added to pure zinc oxide. But additional electrons mean more absorption of infrared light, and less light means less solar energy can pass through the film to generate current.

The Luxembourg–TDK team modified the process so that the pure, undoped zinc oxide film would have fewer, faster-moving free electrons even without the addition of aluminum.

“Our multidisciplinary team, benefitting from the exchange of knowledge across countries, had the idea to add an additional component—another gas plasma—in the so-called sputter process. This makes the material conductive even without aluminium,” says Siebentritt.

The team used low-voltage radio frequency (RF) biasing during deposition to make the films more conductive. “The films prepared with additional RF biasing possess lower free-carrier concentration and higher free-carrier mobility than Al-doped ZnO (AZO) films of the same resistivity, which results in a substantially higher transparency in the near infrared region (NIR),” states the paper’s abstract. “Furthermore, these films exhibit good ambient stability and lower high-temperature stability than the AZO films of the same thickness.”

The result is a pure film with conductivity comparable to those that contain aluminum, but with better transparency and fewer electrons standing in the way of absorption, says lead author Matěj Hála.

The paper is “Highly conductive ZnO films with high near infrared transparency” (DOI: 10.1002/pip.2601).

Author

Jessica McMathis

CTT Categories

- Electronics

- Energy

- Material Innovations

Related Posts

Sports-quality ice: From pond side to precision Olympic engineering

February 12, 2026

Solid-state batteries turn heads at CES 2026

January 29, 2026