Air Force researchers are investigating ways to boost the performance of aerospace mirrors, while cutting in half the cost and time required to manufacture them. No wonder! It takes about two years and nearly one million dollars to produce a one-meter, lightweight glass aerospace mirror, according to the AF Research Lab’s Materials and Manufacturing Directorate. The MMD has responsibility for developing, producing and maintaining materials used in AF aircraft, missiles, rockets and ground-based military systems.

Aerospace mirrors are key components of everything from surveillance-and-reconnaissance systems to transformational communications networks, directed-energy technology, laser-radar devices and large, high-powered telescopes. Hence MMD’s concern with manufacturing these mirrors in the most efficient and cost-effective way. Until recently, “state-of-the-art” mirror manufacturing meant using monolithic glass. Appealing because of its ability to be bent into diverse shapes, precisely ground and “polished to an angstrom-level surface finish,” monolithic glass also possesses another important asset – a “coefficient of thermal expansion that can be chemically tailored to be near zero ppm/°C,” say MMD’s Lawrence Matson and Pete Meltzer Jr. This coefficient of thermal expansion “minimizes distortion of the optical surface caused by thermal excursions during service,” Matson and Meltzer explain. This advantage has enabled MMD to form mirrors with an areal density of about 15 kg/m2, an accomplishment that took place during MMD’s Advance Mirror System Demonstrator Program.

During this program, MMD was able to achieve a 50 percent reduction in mirror weight and fabrication costs compared with those required for construction of the Hubble Space Telescope. Today, however, it appears MMD researches have maxed-out the benefits of monolithic glass. It’s unlikely any more weight or cost reductions can be squeezed from monolithic glass because its structure offers low-elastic modulus, strength and fracture toughness,” say Matson and Meltzer. “Continued lightweighting would result in very fragile structures that would be difficult to polish and would fail catastrophically with a single handling mishap or during launch.” And, so, like fickle fans abandoning an aging superstar, AF researchers are abandoning monolithic glass in favor of new material up-and-comers.

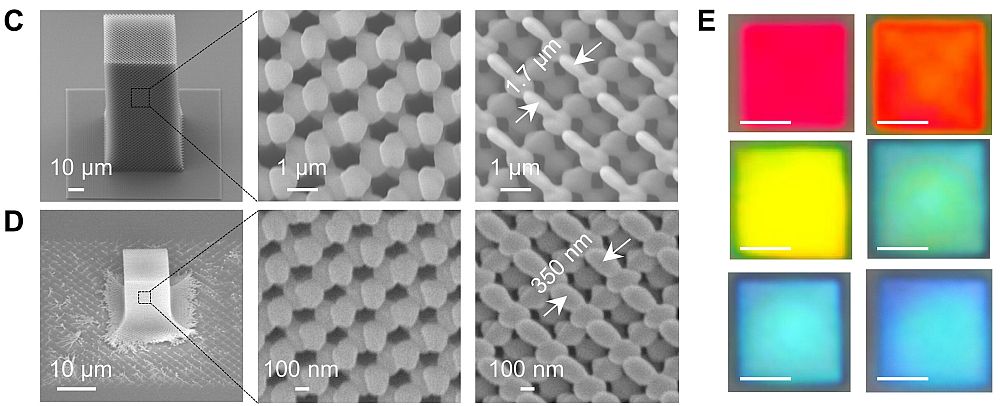

To date, the most promising of these have been ceramic, metal and polymer hybrids and composite materials produced in one of two ways – by using either replicated nanolaminate foil technology pioneered by government labs or by sol-polymer-spinning technology. In either case, Matson and Meltzer say CTE matching is mandatory for success. “Both of these approaches require materials that are CTE-matched in order to obtain and keep the correct contour and smoothness of the optical surface during fabrication and operation,” they advise, indicating MMD’s focus on finding new foil chemistries with CTEs in the zero to 3ppm/°C range. MMD researchers also have discovered that replicated nanolaminate hybrid/composite mirror systems require “CTE-tailored bonding agents” to connect the replicated foil to unpolished structural substrates. To solve this problem, MMD researchers are creating “nanosized, negative CTE particles that can be uniformly dispersed in potential bonding medium, such as organic and inorganic polymers, aero gels and glass sols [and] could also be used to spin an optical surface of visible quality onto unpolished structural substrates,” the researchers said. The two have found they must use nano-sized powders to assure “uniform dispersion and to minimize print-through distortions on the optical surface.” With material solutions in the works, the MMD research team is now turning its attention to finding uniform, stress-free, reflective coatings and dielectric stacks for large mirror systems. It believes the result will be lighter, better, cheaper and faster-to-make aerospace mirrors suitable for any DOD or NASA application.

CTT Categories

- Material Innovations

- Nanomaterials