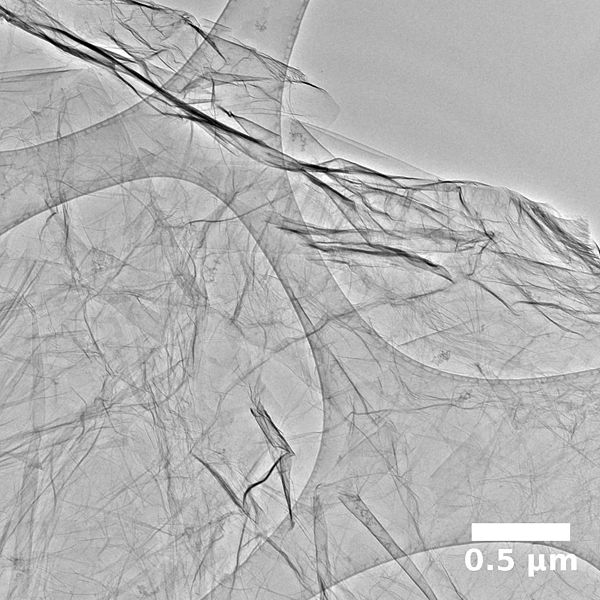

[Image above] Graphene viewed through high resolution transmission electron microscopy (HRTEM). Credit: materialesnano.com; Wikimedia CC BY-SA 3.0

The race to find the answer for manufacturing cost-effective, commercially viable graphene might have just reached a new level.

As the time-to-market gap for commercially viable graphene in electronic applications continues to shrink, researchers at National Cheng Kung University in Taiwan have developed a simple, cost-effective approach to produce graphene in a way that they say broadens the material’s potential commercial applications—they’re calling it ‘defective’ graphene.

The method is electrochemical exfoliation—an “electrochemical approach, which allows defects to intentionally be created in the graphene, altering its electrical and mechanical properties and making the material even more useful,” according to a news release from the Institute of Physics about the research.

According to the paper’s abstract, the process starts with solvent intercalation, which influences thickness of the resulting graphene. The team then uses electrochemical water decomposition to bubble gas through graphite, exfoliating individual graphene sheets.

Varying the voltage allows researchers to control graphene’s thickness, flake area, and number of defects. These all alter properties of graphene and increase the material’s potential for a broader range of commercial applications.

“Graphene is basically a metal, so it’s somewhat boring,” explains Mario Hofmann, a researcher at National Cheng Kung University, in the release. “But when you start adding defects you begin to get interesting effects.”

Mario Hoffmann holds an example set up of the electrochemical synthesis. Credit: Mario Hoffmann; IOP Publishing

The researchers use a “system of pulsed instead of continuous voltages, allowing them to unravel the exfoliation mechanism,” the release explains. Just by monitoring the solution’s transparency, the team found it could gather “quantitative information on the efficiency and onset of exfoliation.”

By having precise control over the types of defects, Hoffman and his team say this could uncover more potential uses for graphene in not just electronic applications, but drug delivery, too.

And Hoffmann and his team aren’t the only ones on a mission to develop graphene that can be used in a broader range of commercial applications.

The National Physical Laboratory’s Quantum Detection Group recently published research that examines the hydrophobicity of epitaxial graphene, which could pave the way for developing new methods to better tailor graphene coatings to applications in medicine, electronics, and more.

The ‘defective’ graphene paper, published in IOP Science’s Nanotechnology, is “Controlling the properties of graphene produced by electrochemical exfoliation” (DOI: 10.1088/0957-4484/26/33/335607).

The NPL paper, published in the American Chemical Society’s ACS Nano, is “Thickness-dependent hydrophobicity of epitaxial graphene” (DOI: 10.1021/acsnano.5b03220).

Author

Stephanie Liverani

CTT Categories

- Manufacturing

- Material Innovations

- Nanomaterials