Surfaces of artificial implants that mimic natural structures are expected to improve biocompatibility by enhancing the connection between the living bone and the surface. The challenge is to create such multiscaled surfaces with common production facilities. Particular laser process parameters may be one way to the desired surface structure.

Anil Kumar Kurella and Narendra Dahotre from the Department of Materials Science and Engineering at the University of Tennessee now report calcium phosphate CaP–TiO2 coatings with multiscale features on Ti alloys via laser surface engineering for enhanced biocompatibility. The authors have deposited a layer of CaP tribasic material onto a Ti alloy surface by air spraying. Laser processing at multiple speeds on these surfaces generates coatings of different morphology and chemistry.

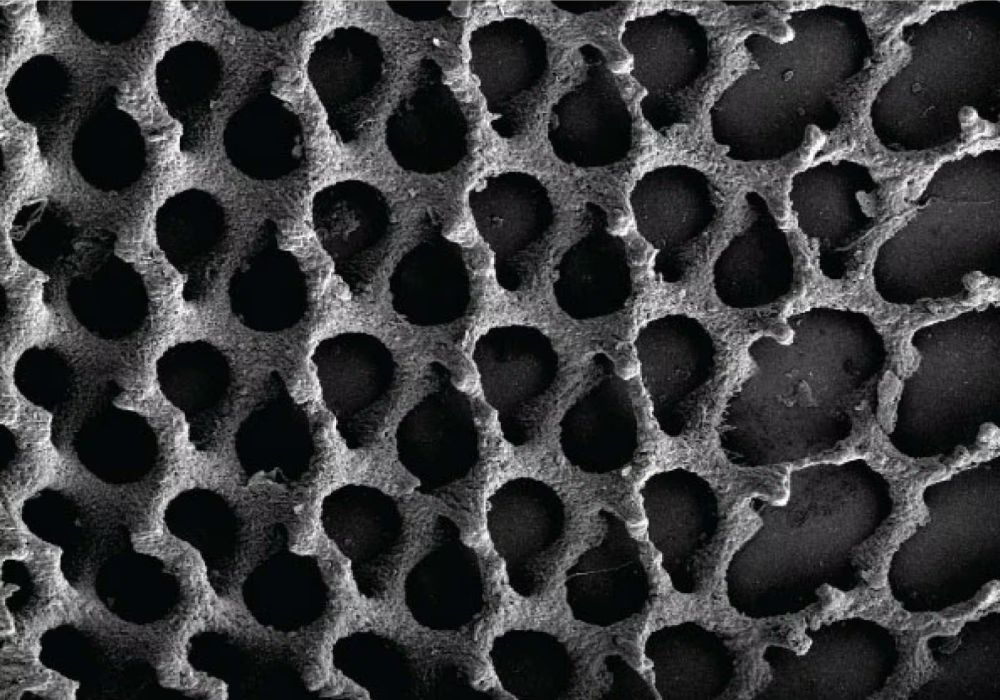

Scanning electron microscopy shows the porous nature of the laser-processed surfaces. The nature of porosity varies with processing speeds: At lower speeds TiO2 is the abundant phase, while at medium and higher speeds CaTiO3 and CaP are the preferred phases. CaP–TiO2 features self-assembled into circular rings; CaTiO3 evolved into star-shaped features at the center of these circular rings.

The authors correlate the different morphologies arising from the different processing speeds with biomimetic precipitation of hydroxyapatite on these multi-scaled features, an indirect indication of the biocompatibility of the modified surface. For medium processing conditions, Kurella and Dahotre suggest surfaces with multiscale features, similar to those seen in natural environments. In comparison, a lower processing speed results primarily in porous surfaces of cuboid features and star-shape particles inside. Faster laser-processing conditions produce a mix of reacted and unreacted zones. The latter two are unlike natural structures, this has a negative influence on biocompatibility.

The study shows that a simple modulation of the laser process parameters can improve biocompatibility of artificial implants.

Editor’s note: Martin Grolms is a writer for Material Views

CTT Categories

- Biomaterials & Medical