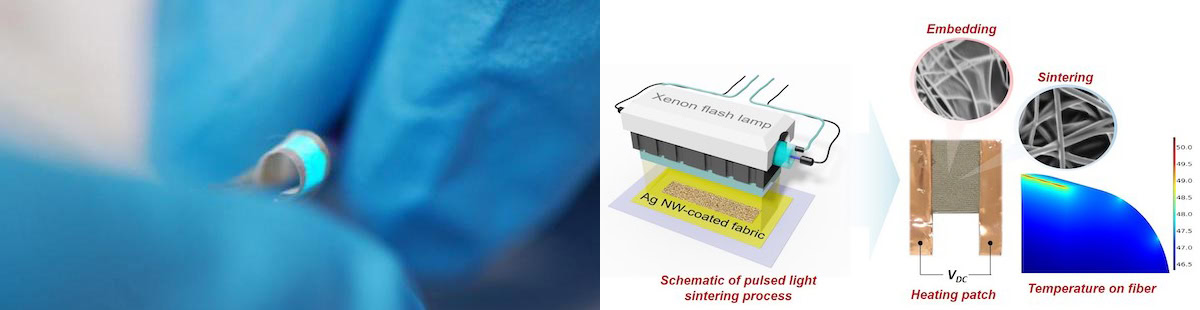

[Image above] Credit: Left, Professor Craciun lab, University of Exeter; Right, Hyun-Jun Hwang and Rajiv Malhotra/Rutgers University-New Brunswick

Wearables are the subject of much research in the past few years. According to Juniper Research, in comparison to conventional activity trackers like Fitbit and Garmin that are expected to increase 20 percent over the next four years, clothing- and ear-based fitness wearables are expected to grow from 4.5 million units in 2018 to nearly 30 million in 2022—an increase of more than 550 percent! Additionally, connected clothing will experience a 102 percent CAGR over the next two years.

Most wearable technology that provides metrics for health and fitness-related activities are designed to be worn as accessories, mainly on the wrist. But in recent years, scientists have been working to incorporate the technology into clothing.

Last year, we reported on clothing that can generate power for military and health care applications, and a study demonstrating carbon nanotube yarns could generate electricity when pulled, stretched, or twisted. Earlier this year, we highlighted experiments with MXenes and polymers on a variety of substrates, including cloth, that show promise for wearables.

As this year comes to a close, here are two new examples of research in wearable tech.

Graphene fibers replace bulky wearable devices

In a collaboration between the University of Exeter engineering department, the Centre for Graphene Science at the University of Exeter, the Universities of Aveiro and Lisbon in Portugal, and CenTexBel in Belgium, researchers developed electronic fibers out of graphene that can be woven into fabric.

What makes this research different from current technology is that the electronic fibers are actually integrated into the material, rather than attached at the surface. “For truly wearable electronic devices to be achieved, it is vital that the components are able to be incorporated within the material, and not simply added to it,” University of Exeter professor in nanoscience and nanotechnology and lead researcher Monica Craciun says in a University of Exeter news release.

The researchers wove graphene fibers into polypropylene fibers to create a material that eliminates the need for electrodes or wires in the semi-flexible devices that have typically been used to create wearable electronic devices.

“This new research opens up the gateway for smart textiles to play a pivotal role in so many fields in the not-too-distant future,” research scientist and former Ph.D. student of Craciun at Exeter Elias Torres Alonso suggests in the release. “By weaving the graphene fibres into the fabric, we have created a new technique to [allow] the full integration of electronics into textiles. The only limits from now are really within our own imagination.”

The team believes their research could not only revolutionize the creation of everyday wearable electronic devices, but could also be used for health monitoring, such as heart rates and blood pressure, and medical diagnostics.

The open-access paper, published in Flexible Electronics is “Graphene electronic fibres with touch-sensing and light-emitting functionalities for smart textiles” (DOI: 10.1038/s41528-018-0040-2).

Silver nanowires heat the body, save energy

If we could heat our clothes instead of buildings, we could save a lot of energy—and money—that goes toward fueling a furnace. That is the thinking behind a new study in Scientific Reports. Researchers from Rutgers and Oregon State University developed heating patches that can be attached to essential areas on clothing that keep people warm, reducing the need to heat entire buildings.

According to the study, heating a building takes nearly half (47 percent) of the energy in the world, and a little over 80 percent of that energy goes toward heating empty spaces in buildings rather than people. “This is important in the built environment, where we waste lots of energy by heating buildings—instead of selectively heating the human body,” Department of Mechanical and Aerospace Engineering assistant professor at Rutgers University–New Brunswick Rajiv Malhotra explains in a Rutgers Today news release.

To create the patches, the researchers fused silver nanowires to polyester fibers using an intense pulsed-light sintering process. The patches are flexible and inexpensive, according to the researchers, and also maintained their durability after being exposed to high temperatures, humidity, bending, and laundering.

The researchers plan to continue their work with other smart fabrics to determine the best locations on the body to place the patches for maximum comfort.

Perhaps our clothing will someday monitor our health and keep us warm(er) while lowering indoor heating costs.

The open-access paper, published in Scientific Reports is “Rapid Pulsed Light Sintering of Silver Nanowires on Woven Polyester for personal thermal management with enhanced performance, durability and cost-effectiveness” (DOI: 10.1038/s41598-018-35650-7).

Author

Faye Oney

CTT Categories

- Material Innovations