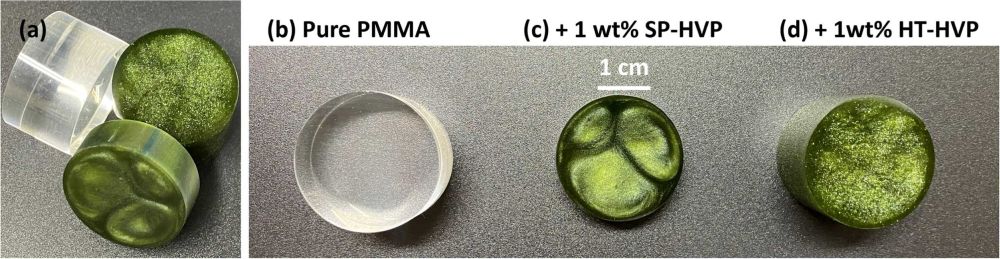

[Image above] a) Photographs of HVP pearlescent pigments dispersed in a poly(methyl methacrylate) (PMMA) matrix. b) Pure PMMA. c) PMMA composites with 1 wt.% HVP (37 μm). d) PMMA composites with 1 wt.% HVP (147 μm). Credit: Cheng et al., Journal of Alloys and Compounds (CC BY 4.0)

Speed, hardness, durability—materials engineers have unlocked unprecedented performance in modern technologies thanks to the careful design of advanced materials. These developments are not just functional—art and fashion have benefited from material advancements as well.

Take, for example, pigments. Pigments are one of the main forms of colorant in today’s world, and researchers have successfully developed more extreme and novel versions of various colors by using chemical and structural design principles to produce new pigments.

Luster is another aesthetic property that researchers have improved using material design principles. Luster describes the gentle sheen or soft glow that is inherent to pearls, and manufacturers in industries ranging from cosmetics to automotives rely on pearlescent pigments to mimic this desirable optical effect in their products.

Pearlescent pigments consist of plate-like particles called platelets, which reflect and refract light between the various platelet layers. Typically, mica and titanium dioxide are used as the base and surface layer platelets, respectively, but the manufacturing process is costly due to specialized equipment and complex chemical procedures.

Substrate-free pearlescent pigments, which are made of single-component platelets without a base layer, exist as well. But only a few materials are known to crystallize into plate-like particles suitable for use as substrate-free pigments, and this limited variety restricts their broader applications.

In a recent open-access study, researchers at Tohoku University in Japan investigated the potential of certain vanadium phosphates to serve as single-component platelets for pearlescent pigment design.

Vanadium phosphates have rich structural diversity due to vanadium’s ability to exist in three oxidation states and the various ways in which phosphate tetrahedra and vanadium polyhedra link together. Of the various compounds, yellow vanadium phosphate dihydrate [VOPO4·2H2O, or VOP] and its hydrated green phase [H0.6(VO)3(PO4)3(H2O)3·4H2O, or HVP] have plate-like morphologies with a high ability to intercalate, which “indicate its potential as a candidate for substrate-free pearlescent pigments,” the researchers write.

The Tohoku researchers used a hydrothermal process to synthesize VOP and HVP that involved hydrogen peroxide, which ensured the vanadium phosphate formed with larger plate-like crystal grains (larger particles are expected to enhance the pearlescent effect).

Analysis of the new VOP and HVP pigments revealed they demonstrate high gloss units and striking iridescent colors comparable to commercial mica-based pearlescent pigments. Unlike the mica-based pigment, though, the VOP and HVP pigments were created in a straightforward and low-cost process.

Based on these results, “We believe that both VOP and HVP are promising candidates for use as substrate-free pearlescent pigments,” the researchers conclude.

A Tohoku press release reports that the researchers plan to improve this process by expanding the color range and improving the stability of the pigments.

The open-access paper, published in Journal of Alloys and Compounds, is “Synthesis of novel colored substrate-free pearlescent pigments of vanadium phosphates with large-size layered platelet morphology” (DOI: 10.1016/j.jallcom.2024.177735).

Author

Lisa McDonald

CTT Categories

- Manufacturing

- Material Innovations