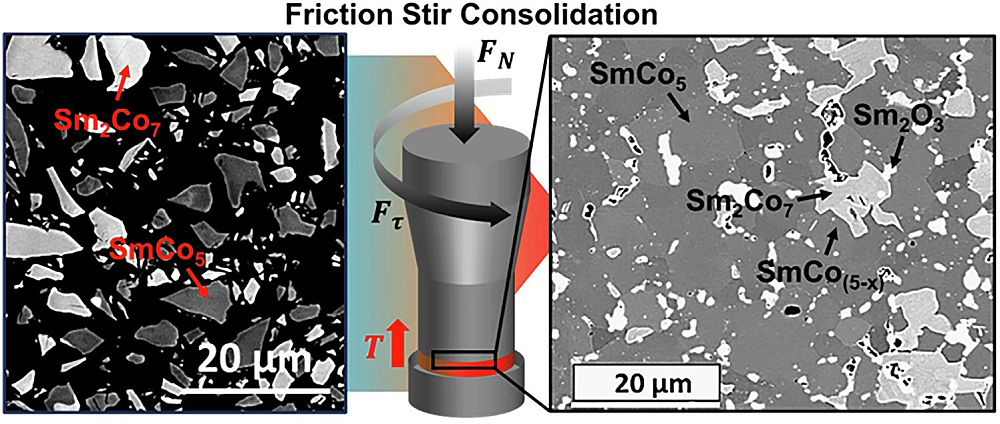

[Image above] Schematic of the friction stir consolidation process and setup, demonstrating change from initial segregated samarium cobalt powder particles into a consolidated sample. Backscattered electron images depict different phases that are present in both steps. Credit: Malakar et al., Nature Communications (CC BY-NC-ND 4.0)

My first experience with magnets was hanging comic strips on the fridge that I cut from the daily newspaper. It was frustrating when some magnets slid down the door once the paper was placed under them, and I wondered how something with such a weak force could ever have applications beyond decorative uses.

An incident in college changed my perspective, however. I was in the physics lounge as several classmates debated if the magnets for an outreach demonstration were as strong as the professor said. They decided to stack the magnets against the professor’s advice, and only after much effort did they successfully pry the magnets apart again—after which they kept the magnets well away from each other to avoid future mishaps.

While the demo magnets were magnitudes more powerful than the fridge magnets, they still barely scratched the surface of how strong permanent magnets can be. Take MRI machines, for example, which generate magnetic fields strong enough to pull oxygen tanks or wheelchairs across the room.

To create the strong magnets that are used in everything from wind turbines to junkyard scrap sorters, manufacturers typically sinter metal alloy powders into a bulk solid at high temperature and under high pressure. But this process is complex and time consuming, and it often results in the creation of flawed magnets due to uneven distribution of porosity and oxidation throughout the magnetic material.

In a recent open-access paper, researchers from North Carolina State University and Pacific Northwest National Laboratory developed a single-step, energy-efficient processing method to create high-performance permanent magnets.

The new method is based on friction stir consolidation, a solid-phase manufacturing technique that is primarily used to recycle metal machining scraps. In this process, metal powders, scraps, or chips are placed in a chamber under relatively low pressure and heated to a temperature just below the melting point. The softened material then can be stirred with a rotating tool and eventually cooled to form solid blocks.

“Because the metal is not exposed to high heat and doesn’t actually melt, this process results in less oxidation and unwanted phase transitions in the material,” says Bharat Gwalani, corresponding author and assistant professor of materials science and engineering at NC State, in a press release. “Also, while we are applying pressure, it’s less than one megapascal (MPa), whereas conventional magnet manufacturing techniques apply more than 100 MPa.”

The researchers investigated the possibility of using friction stir consolidation to process brittle magnetic particles by creating samarium cobalt magnets, which are known for their corrosion resistance and maintaining their magnetic properties at high temperatures (up to 300°C). These magnets can also form multiple intermetallic phases with a range of magnetic responses, which is why the fact this processing method avoids unwanted phase transitions is especially beneficial.

When conducting microstructural analysis of the samarium cobalt magnets, the researchers discovered another exciting benefit of this manufacturing method—it significantly reduced porosity in the magnetic material.

“This [reduction in porosity] is because conventional techniques apply pressure in only one direction, which means the pressure is applied largely to the top and bottom of the material, forcing porosity into the center,” Gwalani says in the press release. “Because our technique involves rotating the material as pressure is applied, that pressure is distributed throughout the material.”

Additionally, while conventional techniques require an external heat source, the new processing approach relies on frictional heating caused by the metal alloy powder particles rubbing together. As a result, heat is generated exactly where it is needed, and the targeted heating—along with the even distribution of pressure—results in the reduction of porosity. Consequently, the magnets demonstrate improved mechanical properties as well.

With the efficacy of this processing technique’s applicability to magnet manufacturing confirmed, the researchers are now experimenting with developing magnets that incorporate non-magnetic binder agents.

“We want to make low-density, tougher magnets that are less reliant on difficult-to-obtain rare-earth materials,” Gwalani says in the press release.

The open-access paper, published in Nature Communications, is “In-situ thermo-mechano-chemical transformation and consolidation of Sm–Co powders via a single-step route for bulk magnet fabrication” (DOI: 10.1038/s41467-025-62804-9).

Author

Lisa McDonald

CTT Categories

- Manufacturing