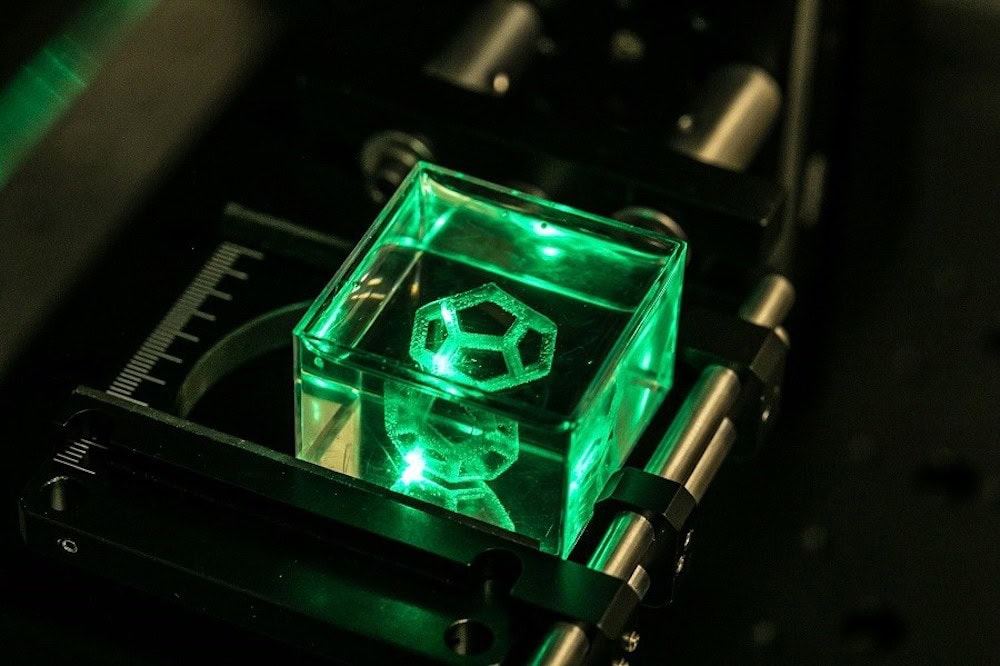

[Image above] A picture of the developed 3D printing laser system based on two-photon polymerization. The laser source is a commercial femtosecond diode pumped ytterbium amplified laser. Credit: Laurent Gallais, The Fresnel Institute and École Centrale de Marseille

If you have attended Ceramics Expo at all in the past few years, you know that additive manufacturing is a topic of big interest for the industry.

Additive manufacturing, or 3D printing, is a group of manufacturing techniques that fabricate three-dimensional objects from computer models. Selective laser sintering, fused filament fabrication, and binder jetting are just a few of the many techniques that fall under the additive manufacturing umbrella.

Plastic and metal additive manufacturing are both well-established markets, and ceramics additive manufacturing is gaining ground in certain industries, especially the medical and dental fields. In contrast, glass additive manufacturing remains a long way from market, due in part to challenges the material presents to traditional additive manufacturing techniques, such as a high melting point.

The last few years saw significant advances in development of 3D printing processes for glass structures, and we featured a three–part series on CTT on different techniques in 2019. However, the door to developing new and better processes remains wide open, and three researchers in France recently took the opportunity to explore another method that has not previously been covered on CTT.

Two-photon polymerization process for 3D printing glass

Laurent Gallais, researcher and associate professor at the Fresnel Institute and École Centrale de Marseille in France, and his colleagues Thomas Doualle (École Centrale de Marseille) and Jean-Claude Andre (University of Lorraine) published a recent paper in Optics Letters that explores the use of two-photon polymerization to 3D print glass.

Polymerization is a process of reacting monomer molecules together in a chemical reaction to form polymer chains or 3D networks. Researchers have exploited photopolymerization-induced phase separation of hybrid resins or hybrid ceramic precursors that can undergo both the photopolymerization reaction and a sol-gel process to create transparent silica parts.

However, “The common approach in these works … is to create multiple two-dimensional (2D) slices and then stack these slices to form 3D objects. This layer-by-layer process has numerous limitations: manufacturing time, mechanical anisotropy properties, shrinkage, shear stress, robust implementation time of layers of constant thickness, need for the creation of supports for complex parts and their elimination in a post-processing operation, etc.,” the researchers write.

They argue that most of these drawbacks are linked to the layer-by-layer procedure. Direct creation of 3D structures would therefore overcome these limitations, and that is exactly what two-photon polymerization offers.

“[In two-photon polymerization], polymerization is activated by the simultaneous absorption of two photons of an intense laser radiation, only taking place at high laser intensity within a spatially localized focal spot in the monomer with a photosensitive initiator,” they write. “Then, with the [two-photon polymerization] technique, it is possible to polymerize volumes inside the polymer liquids contrary to the conventional one-photon-based process (such as stereo-lithography), in which polymerization takes place only on the liquid surface or close to it.”

To test the potential of 3D printing glass through two-photon polymerization, the researchers mixed a high-viscosity transparent resin and loaded it with silica nanoparticles until the dispersion reached 50 wt. % of nanoparticles of silica. A photoinitiator (1 wt. %) then was added to absorb the laser light and initiate two-photon polymerization.

The researchers used a commercial femtosecond diode pumped ytterbium amplified laser to trigger two-photon polymerization of the dispersion. Then, the solidified structures were rinsed with isopropyl alcohol and underwent thermal post-treatments to transform the polymerized green parts into silica glass.

(A video of the laser used to polymerize the dispersion is available on The Optical Society website.)

The final silica glass parts did not show any cracks or breakages, and the measured density of the samples was 2.18 g/cm3, which is close to the theoretical value of amorphous silica. These results illustrate that the researchers “optimized the thermal post-treatments and showed the importance of them on the success of the global process.”

A press release by The Optical Society notes that the researchers are working to make the technique more practical and reduce cost by experimenting with less expensive laser sources, for example. However, the results already show that “Our approach could potentially be used to produce almost any type of 3D glass object,” Gallais says.

The paper, published in Optics Letters, is “3D printing of silica glass through a multiphoton polymerization process” (DOI: 10.1364/OL.414848).

Author

Lisa McDonald

CTT Categories

- Glass

- Manufacturing

- Material Innovations

Related Posts

Sports-quality ice: From pond side to precision Olympic engineering

February 12, 2026