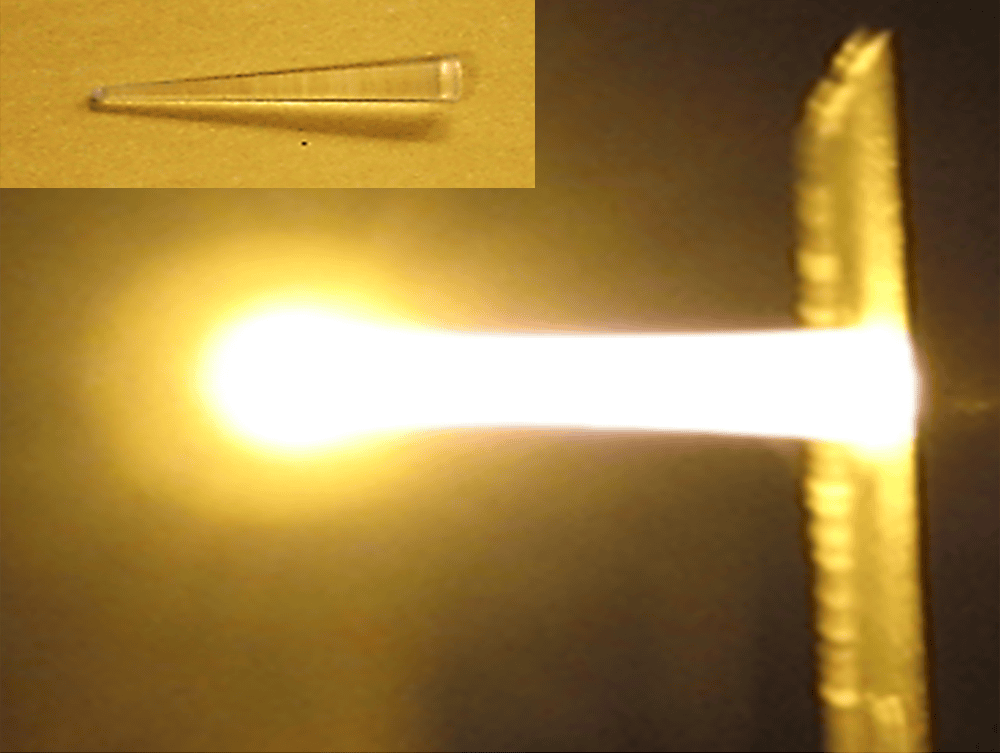

[Image above] Example of the transparent yttria alumina garnet ceramic cone used in a new ultrafast photonic heating system, which can reach temperatures of up to about 1,900°C in approximately 200 milliseconds. Credit: Ikesue, Aung, and Kamimura

In the past year, one topic I’ve come to learn a lot more about is transparent ceramics.

Transparent ceramics are polycrystalline ceramics in which the microstructure is finely tuned to minimize scattering of visible light, thus allowing light to pass through. These materials “have emerged as promising candidates to replace their single-crystal counterparts because of their outstanding advantages, which include low cost, large-scale production, malleability, and high mechanical strength,” a recent open-access review article explains.

Several ceramic compounds in particular have received a lot of attention as transparent ceramics, including aluminum oxynitride for armor applications and yttria alumina garnet (YAG) as a host material for solid-state lasers.

In regard to YAG, investigation of this compound as a host material for lasers really kicked off in the 1990s with the work of ACerS Fellow Akio Ikesue.

Ikesue is a Japanese researcher and founder of World Lab. Co., a company that develops special ceramics such as ceramic Faraday rotator elements for fiber laser isolators and optical communication isolators. He is renowned in the field of transparent laser ceramics because his YAG-based lasers were the first to achieve laser performances close to single crystals, as described in a Journal of the American Ceramic Society 1995 article.

Ikesue has continued to publish extensively on the use of transparent ceramics in lasers, but today’s CTT focuses on his use of YAG in a different application—a photonic heating system.

Photonic heating—light is the new heat

Next to convection and conduction, thermal radiation is the third method by which heat is transferred from one place to another.

Thermal radiation is the term for electromagnetic radiation that is emitted by an object as a function of its surface temperature. It results from the acceleration of electrons when particles in the object collide due to random motions.

All matter with a temperature greater than absolute zero emits thermal radiation, and on Earth, thermal radiation is most often emitted in the infrared region of the electromagnetic spectrum (i.e., roughly 700 nm to 1 mm). However, thermal radiation can be emitted in the visible part of the UV spectrum as well. For example, our sun emits thermal radiation principally in the visible spectrum.

We can detect thermal radiation with various instruments to learn more about the objects emitting the radiation, such as one photodetector I described last month. However, in recent years, scientists have become interested in harnessing thermal radiation to generate heat in a controlled fashion—in other words, to create heating systems based on photon energy.

Traditionally, such an idea was viewed as impracticable due to Planck’s law, which forms our basic understanding of thermal radiation. This law sets an upper limit for radiative heat transfer between bodies at different temperatures, meaning it limits how much heat a photon-based heating system could produce.

However, Planck’s law was derived under the assumption that all dimensions involved in a thermal problem are much longer than the thermal wavelength. But in recent years, our advances in nanomaterials and engineered nanostructures means the Planckian limit can be greatly overcome—making the idea of a photonic heating system feasible.

To date, no commercial photonic heating systems exist. But Ikesue hopes to help change that with his latest research.

Ultrafast heating system by photon energy

Ikesue explains in an email that he established the photonic heating technology described in his recent research brief around 25–30 years ago, but he did not share it at a conference nor submit a technical paper. However, because the concept of flash heating has become “hot news” lately, he started looking into photonic heating with renewed interest.

In the recent brief Ikesue wrote with colleagues Yan Lin Aung (World Lab. Co.) and T. Kamimura (Osaka Institute of Technology), they describe a YAG-based photonic heating system that Ikesue says has a heating rate about 100 times faster than the ultrafast high-temperature ceramic sintering method I described in mid-May.

Schematic diagram of the wireless photonic heating system and (b) rapid flashing after irradiation of photonic energy to the ceramic heating element. Credit: Ikesue, Aung, and Kamimura

In their photonic heating system illustrated above, photons are produced at the “photon generator.” In this study, a semiconductor laser diode was used as the generator, but Ikesue says they plan to use light emitting diodes in the future.

Photons then are sent through an optical fiber and focusing lenses to the transparent YAG (Y3Al5O12) ceramic. The ceramic can be either rod-shaped or cone-shaped, but the researchers note cone-shaped ceramics allow for finer and more accurate localized heating, as the tip can be reduced to about 10 μm.

Almost 100% of the photon energy passes through the ceramic to the tip, which is doped with a special element for heat generation. The tip’s temperature increases rapidly—the time required to reach 1,000ºC is about 100 milliseconds, and the heating rate reaches 10,000ºC per second.

Despite the intense heat, the system requires very little power to operate.

“Photon intensity is only a few W class,” Ikesue says. “If you reduce the hot spot size, it will generate intense heat even with the mW class input.”

In the video below, you can see how a cone-shaped tip allowed the researchers to pattern a 50-μm-wide groove on the surface of an acrylic plate used for LED lighting.

Credit: Ikesue, Aung, and Kamimura

Ikesue says they have not yet done much testing for lifetime durability, but the transparent ceramic heating element should remain stable if used below the ceramic’s melting point. Thus, “If you just use it as heating up, it may last for thousands of hours,” Ikesue says.

There still is much unknown about the full potential of the photonic heating system, and Ikesue and his colleagues are continuing to investigate different system components. For example, they showed a wired system, in which the optical fiber is connected directly to the ceramic, demonstrates comparable performance to the wireless system. They also are testing other transparent ceramics besides YAG, such as sapphire, and the wavelength of light used.

“The wavelength [in this study] is 800 to 950 nm, depending on the type of heat generating part. I plan to use wavelengths in the 450-nm band in the future,” Ikesue says.

If you are interested in learning more about this research or wish to collaborate on future studies, contact Ikesue at poly-ikesue@s5.dion.ne.jp or Yan Lin Aung at poly-yan@r2.dion.ne.jp.

Author

Lisa McDonald

CTT Categories

- Energy

- Material Innovations