Thanks to researchers at Rensselaer Polytechnic Institute in Troy, N.Y., scientists now have a way to measure nanomaterials as they grow. According to an RPI press release, the newly discovered technique is expected to aid in the creation of superior nanomaterials and may lead to the development of more efficient solar panels and magnetic data storage.

Details of the discovery have been published in a paper entitled, “Surface Texture Evolution of Polycrystalline and Nanostructured Films: RHEED Surface Pole Figure Analysis,” in the Journal of Physics D: Applied Physics. Gwo-Ching Wang, head of physics, applied physics and astronomy at Rensselaer, is one of the technique’s discoverers. She says the new technique is based on reflection high-energy electron diffraction, explaining that conventional RHEED systems create an interference pattern on a nanomaterial’s surface. This pattern, she notes, only provides partial information and offers “only a snapshot in time” of the nanomaterial’s growing surface. Wang says the Rensselaer team has modified the traditional RHEED technique by rotating the substrate on which the nanomaterial is grown. In doing so, the team produced “a diagram containing the complete information on the crystal orientation distribution of the growing surface.”

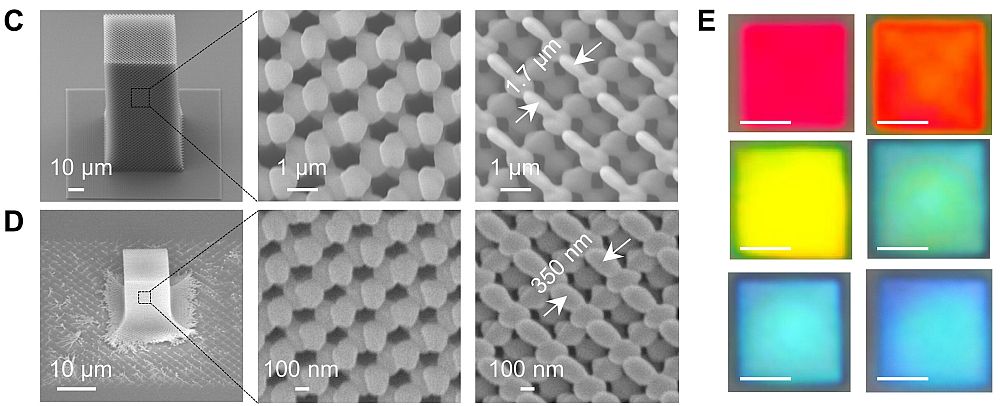

According to the RPI press release, the creation of surface crystal-orientation diagrams is important for revealing the nature of the growth of such nanostructures as nanodots, nanorods, and nanoblades. “These structures have strong energy and data-storage capabilities, but their orientation can change dramatically over time, making their use in consumer products problematic because of their unpredictability,” the release states. Wang says the newly developed technique differs from other common techniques, including X-rays, which measure the entire piece of material and the substrate it is grown on. In contrast, the Rensselaer’s technique provides more detail and data because it maps only a few nanometers’ growth at a time. “The problem with creating high-quality polycrystalline materials is that you need a powerful technique to monitor them in nanocscale dimensions as they grow, so you can quickly work on recreating the material to maximize its efficiency,” Wang comments. “The new RHEED technique really allows researchers to create a material, see how it formed and, then, turn around and recreate the most ideal version of that material without extensive experimentations,” she claims.

In addition to Wang, the Rensselaer’s research team included Toh-Ming Lu, a professor of physics, applied physics and astronomy, and Fu Tang, a postdoctoral research associate. The team has presented their findings to DOE, the American Vacuum Society and at various conferences throughout the world. “Everywhere we go, people have become more excited about the possibilities that it [the new technique] opens up for them in their own research,” Wang notes, indicating the technique can easily be replicated.

CTT Categories

- Material Innovations

- Nanomaterials