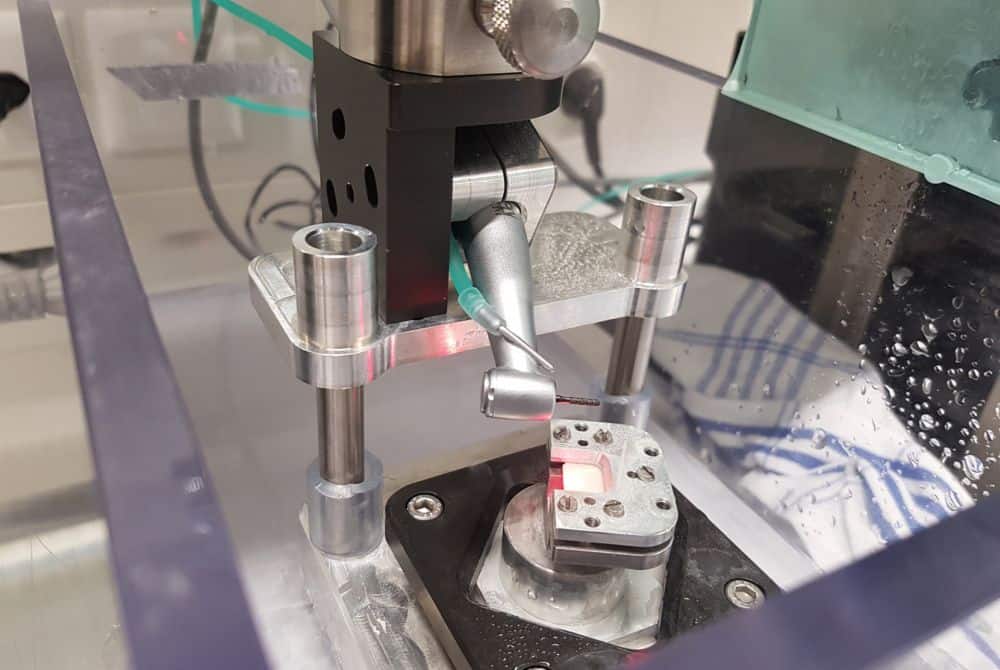

[Image above] Custom-made holder connected with universal testing machine. Handpiece with water cooling positioned parallel to zirconia specimen. Credit: Hunziker et al., The Journal of Prosthetic Dentistry (CC BY 4.0)

Ceramics are ubiquitous in the dental industry, with applications in prosthetics, fillings, orthodontic appliances, cosmetic products, process materials, preventive products, toothpaste, and more.

All-ceramic crowns, such as alumina, lithium disilicate, and yttria-stabilized tetragonal zirconia, are some of the most readily recognized examples. They are the most common crown type because of their strength, ease of fabrication, and aesthetics.

However, their strength can be a double-edged sword when it comes time to replace the crowns, particularly those made from zirconia.

“Because of their high strength, the removal of zirconia restorations is challenging and time consuming, taking up to 1.5 to 7 times longer than for lithium disilicate ceramic or leucite ceramic,” researchers write in a recent open-access paper.

The researchers come from the University Center for Dental Medicine at the University of Basel, Switzerland. They explain that ceramic restorations typically are removed by sectioning the buccal (cheek-side) and lingual (tongue-side) surfaces of the restoration with diamond rotary instruments.

When cutting harder materials such as zirconia, dentists tend to increase the applied load to improve cutting efficiency. But increasing the load causes more heat to develop during the process, which in extreme cases may result in thermal injury to bone tissues around the restoration.

While studies show that water cooling can mitigate heat development, the benefits of a different approach—using diamond rotary instruments marketed specifically for cutting zirconia—are much less clear.

“…. cutting efficiency [of these zirconia removal diamond rotary instruments] is similar to or less than that of conventional diamond rotary instruments,” the researchers write.

More studies are needed, though, to truly compare these instruments. For example, the researchers note that studies to date operated the handpieces at high speeds of 150,000 to 200,000 rpm but not at the slower 40,000 rpm often used in Western Europe.

Additionally, previous studies focused on removing 3 mol% yttria-stabilized tetragonal zirconia polycrystal. While this formulation dominates the market due to its high strength, zirconia with higher yttria percentages are used as well due to better aesthetics, despite their diminished strength.

In the new study, the researchers tested cutting performance of three different diamond rotary instruments on specimens made of 3 mol% yttria-stabilized tetragonal zirconia polycrystal (3Y-TZP) and 4 mol% yttria-stabilized zirconia polycrystal (4Y-PSZ). The instruments included two marketed specifically for zirconia removal (JOTA Zir Cut Z838L and Intensiv ZirconCut Zr02/10) and one conventional course-grit diamond rotary instrument (Intensiv FG 334/6).

Cutting speeds of 40,000 rpm using two different load applications (2 N and 6 N) were examined, along with the maximum temperatures reached at the tip of the diamond rotary instruments, change in surface roughness parameters of the diamond rotary instruments, and composition. A water cooling rate of 90 mL/min was used for testing, higher than the manufacturer’s recommendation of 50 mL/min (Intensiv SA).

Overall, the conventional diamond rotary instrument Intensiv FG demonstrated the best performance. At a 6 N load, the overall mean cutting time was 35 seconds through 3Y-TZP and 28 seconds through 4Y-PSZ. In contrast, JOTA Z838L gave the slowest performance, with mean cutting times of 340 seconds through 3Y-TZP and 293 seconds through 4Y-PSZ at a 2 N load.

All diamond rotary instruments showed higher temperature development with a 6 N load compared with a 2 N load. The highest maximum temperature was observed with JOTA Z838L at a 6 N load for 4Y-PSZ (37.3°C), while the lowest was observed with the Intensiv ZirconCut on 3Y-TZP with a 2 N load (24.6°C).

A higher cutting efficiency also resulted in increased surface wear of the diamond rotary instruments. Before use, the Intensiv ZirconCut and Intensiv FG had similar surface roughness values, which were higher than for JOTA Z838L. But after use, especially with the 6 N load, diamond particles wore off and even fractured from the embedding material, thus excluding the instruments from reuse.

The researchers propose the varying performance of the diamond rotary instruments may be attributable to the composition of the diamond particles and the embedding material.

“Diamond particles of IZC [Intensiv ZirconCut] and IFG [Intensiv FG] displayed a high carbon content, while diamonds of JOT [JOTA Z838L] demonstrated impurities of hafnium and nickel. The impurities may have reduced the hardness of the diamonds and, consequently, the cutting performance,” they write.

Regarding embedding material, the JOTA Z838L and Intensiv FG diamond rotary instruments used nickel alloys. Nickel is the leading contact allergen in most industrialized countries worldwide.

“The actual risk to patients from diamond rotary instruments containing nickel has yet to be determined. Nevertheless, exposing patients with high allergy potential to diamond rotary instruments with nickel alloys is not recommended,” the researchers write.

In contrast, the Intensiv ZirconCut featured a resin-based embedding material, which “may be a valuable alternative to nickel alloys in the future,” they suggest.

Overall, based on these results, the researchers reaffirmed that diamond rotary instruments marketed for cutting zirconia do not perform better or generate less heat than conventional diamond rotary instruments.

The open-access paper, published in The Journal of Prosthetic Dentistry, is “Evaluation of diamond rotary instruments marketed for removing zirconia restorations” (DOI: 10.1016/j.prosdent.2022.08.009).

Author

Lisa McDonald