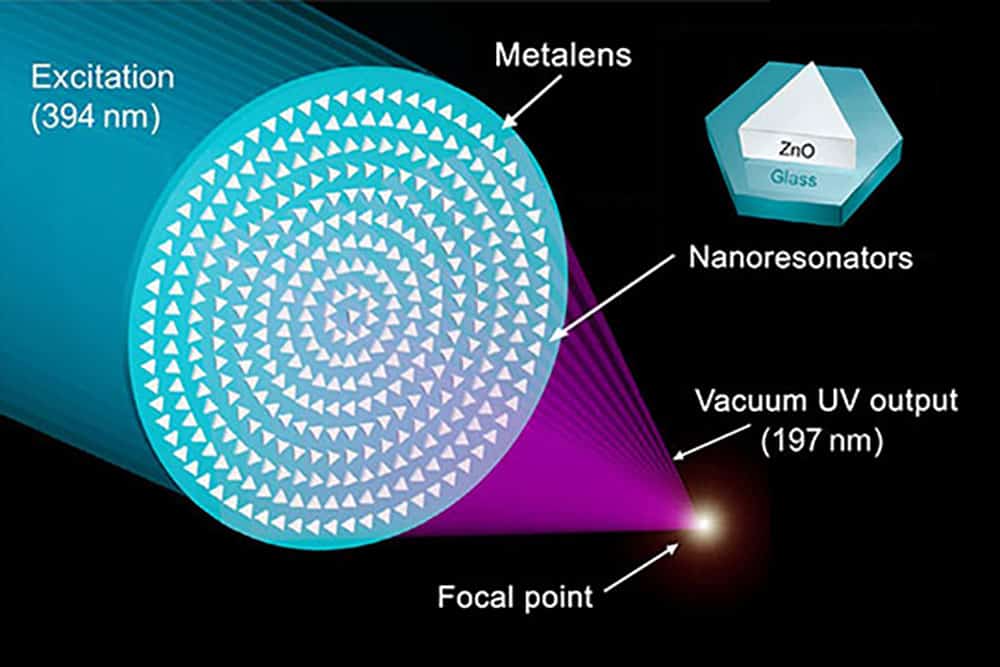

[Image above] A new metalens developed by Rice University photonics researchers can both generate and manipulate vacuum UV light. Credit: M. Semmlinger, Rice University

It is entering the time of year during which I must remember sunscreen or risk turning into a bright red (and painful) tomato whenever I go outside. Yet while ultraviolet light is often identified as the culprit behind sunburns, not all UV light is equally culpable.

Just as visible light can be divided into different colors based on its wavelength, the UV radiation spectrum is divided into four regions: UVA, UVB, UVC, and vacuum UV. UVA and UVB are the main culprits behind sunburns. UVA consists of the longest wavelengths (320–400 nm) and is associated with skin aging. UVB consists of slightly shorter wavelengths (280–320 nm) and is associated with skin burning.

UVC (200–280 nm) and vacuum UV (<200 nm) have more energy than UVA and UVB, which technically makes them more hazardous. However, these wavelengths are readily absorbed by many gases in the atmosphere and so rarely make it past the ozone layer to reach the Earth’s surface.

While it is fortunate for our skin that UVC and vacuum UV light are largely absent from our lower atmosphere, these types of UV light are not all bad. Their tendency to be readily absorbed makes UVC and vacuum UV light useful as a disinfectant by triggering beneficial photochemical reactions. They are also useful in nanoscale processing for this same reason.

The use of vacuum UV light in these applications is limited, however, due to the difficulty of generating and manipulating this shortest of UV wavelengths. Vacuum UV light is typically generated by nonlinear processes in gases, which is not the most convenient or easily integrated approach.

Additionally, once vacuum UV light is generated, focusing it is difficult because almost all types of glass used for conventional lenses will absorb this light. The few vacuum-UV-transmittable materials used for lenses, such as CaF2 and MgF2, are comparably fragile, placing practical limits on thin lens fabrication and design.

So, “New approaches to both VUV [vacuum UV] light generation and manipulation are clearly needed to advance our utilization of this region of the electromagnetic spectrum,” researchers write in a recent open-access paper.

The researchers are led by photonics researchers from Rice University and include colleagues in Taiwan and Hong Kong. In their paper, they propose that a newly designed metalens could solve both vacuum UV challenges.

Metalenses are a specific type of metasurface, or artificially nanostructured interface with subwavelength thickness, that is used to control light. These flat, engineered lenses are constructed of nanoscale arrays of columns or fin-like structures and can focus light without causing a type of image distortion called chromatic aberrations, which conventionally require multiple lenses to correct.

Researchers at the Harvard School of Engineering and Applied Sciences (SEAS) first demonstrated the efficiency of metalenses in 2016. Since then, various research groups have made numerous advancements in metalens design.

In 2018, the Rice University researchers and their colleagues demonstrated that a metasurface made from zinc oxide can convert UVA light into vacuum UV light through a frequency-doubling process called second-harmonic generation. Now, their new work explores whether a metalens made from the same material would be able to both generate and manipulate vacuum UV light.

The researchers used finite-element analysis to design and simulate the metalens’ performance before patterning the actual sheet of transparent zinc oxide using electron beam lithography and reactive ion etching. The pattern consists of concentric circles studded with tiny triangles.

Like the metasurface, the metalens successfully converted 394-nanometer UVA light into 197-nanometer vacuum UV light. In addition, the metalens focused its 197-nanometer output onto a spot measuring 1.7 microns in diameter, increasing the power density of the light output by 21 times.

Though it is too early to say whether the technology can compete with state-of-the-art vacuum UV systems, Naomi Halas, Stanley C. Moore Professor of Electrical and Computer Engineering and director of Rice’s Smalley-Curl Institute, says this work is particularly promising in light of recent demonstrations that chip manufacturers can scale up production of metasurfaces with CMOS-compatible processes.

“This is a fundamental study, but it clearly points to a new strategy for high-throughput manufacturing of compact VUV optical components and devices,” she says in a Rice University press release.

The open-access paper, published in Science Advances, is “Vacuum ultraviolet nonlinear metalens” (DOI: 10.1126/sciadv.abn5644).

Author

Lisa McDonald

CTT Categories

- Material Innovations

- Nanomaterials

- Optics