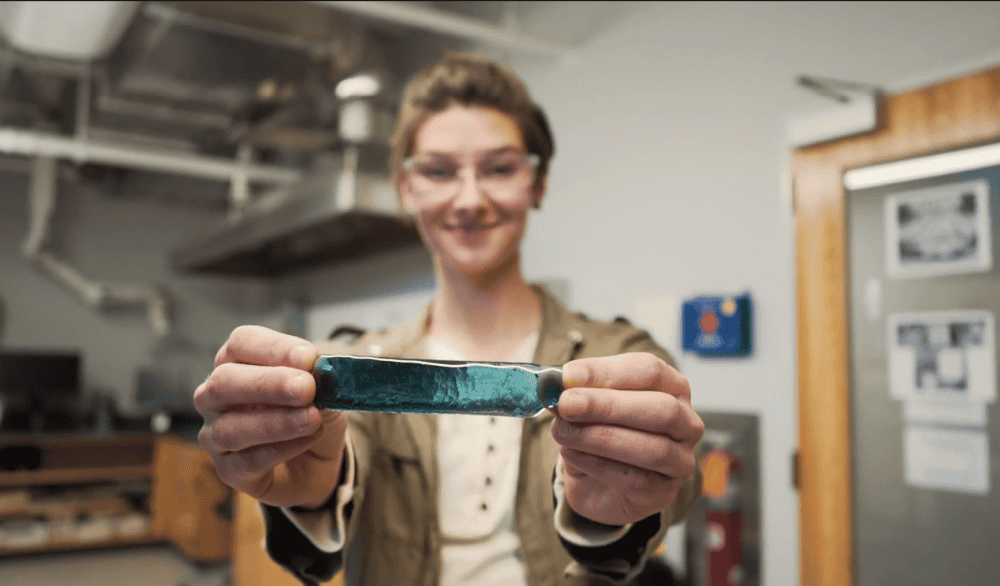

[Image above] Katy Gerace, previously a doctoral student at The Pennsylvania State University and now research and development senior engineer at Vitro Architectural Glass, holds a piece of glass created from recycled bottles. She led research at Penn State in collaboration with Philadelphia-based Remark Glass on the technical feasibility of reusing mixed container glasses of different colors. Credit: PennStateMatSE, YouTube

[Image above] Katy Gerace, previously a doctoral student at The Pennsylvania State University and now research and development senior engineer at Vitro Architectural Glass, holds a piece of glass created from recycled bottles. She led research at Penn State in collaboration with Philadelphia-based Remark Glass on the technical feasibility of reusing mixed container glasses of different colors. Credit: PennStateMatSE, YouTube

In the September 2024 Bulletin that published online last week, the cover story discussed an increasingly pressing environmental challenge in the United States—glass waste.

While the European Union has achieved an impressive more than 80% recycling rate for glass containers, the United States has struggled, reporting just barely more than 30%. A conflux of challenges contributes to this lack of glass recycling in the U.S., but at its core, economics plays the leading role—typically it is not profitable to overcome the existing challenges.

Take single-stream recycling, for instance. In this system, all consumer recyclables are mixed in one bin rather than separated based on material or color. Mixing the recyclables reduces transportation costs and increases collection rates, but it places a burden on material recovery facilities to sort and clean the now-contaminated recyclables.

Some waste streams are so contaminated with metals or organics that manufacturers would rather send the comingled glass to landfills than pay the hefty cost of transforming it into pure single-stream feed stock for new glass melts. But even in cases where recycling is economically favorable, the presence of multicolor glass in the waste stream can introduce compositional differences in the cullet that prevents its use in products with more stringent quality tolerances, such as flat glass.

Adopting dual-stream or multiple-stream recycling, which requires consumers to separate recyclables into different bins based on material and color, would help mitigate this contamination issue. The cost of implementing such a system, however, is still often considered too expensive for municipalities and solid waste companies. (Though the fact that the recycled materials are cleaner and more marketable is swaying some cities.)

As such, many researchers overcome the contamination issue by reusing waste glass for products that can handle high levels of contamination, such as foam glass and supplementary cementitious materials. But the reuse of waste glass may be unnecessarily limited based on a misconception of what counts as “contaminated,” according to researchers at The Pennsylvania State University.

The researchers are Katy Gerace, previously a Penn State doctoral student and now research and development senior engineer at Vitro Architectural Glass, and ACerS Fellow John Mauro, Dorothy Pate Enright Professor of materials science and engineering. In their recent open-access paper, they argue that container glass, which has less stringent quality tolerances than flat glass, can accommodate mixed colored glass waste more easily than previously believed.

Glass is colored by adding different metal oxides to the composition. But as Gerace and Mauro showed in their paper, the main difference between glasses of different colors is not the presence nor absence of certain oxides but rather the amount of each oxide.

“For example, cobalt oxide was identified in each bottle composition; however, the amount of cobalt oxide in cobalt blue bottles (648.6 ppm) was two orders of magnitude larger compared to clear bottles (8.3 ppm) and one order of magnitude larger compared to amber bottles (23 ppm),” they write.

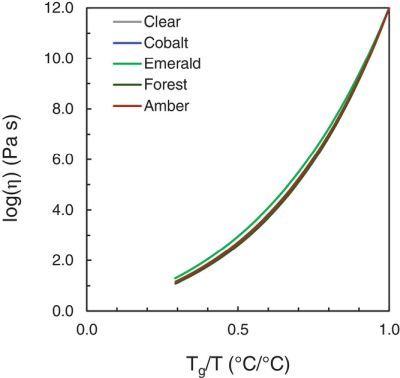

Besides these small differences in the colorants and some fining agents, the average base glass composition of soda–lime silicate was nearly the same across clear, cobalt blue, emerald green, forest green, and amber bottles. This extreme similarity meant the glasses demonstrated a consistent viscosity profile between the different color families, which is necessary for efficient melting and processing.

As such, “color contamination is not a technical risk, but instead, an economic risk as color contamination impacts the optical properties and aesthetic of the final product,” they explain.

Bottle glass viscosity for each color family modeled using the MYEGA equation. Credit: Gerace and Mauro, International Journal of Ceramic Engineering & Science (CC BY 4.0)

Though stringent color profiles may be necessary for some container manufacturers, for companies such as Remark Glass, a Philadelphia-based glass reuse business that partnered with Gerace and Mauro on this project, the focus is on keeping glass waste out of landfills more so than exact color matches. But even if the reused colored glass is not an exact shade, a homogenous (consistent) color can still be achieved by adjusting the particle size of the cullet and the temperature and time of the remelting process.

Ultimately, what this study shows is that the major risk of reusing glass from single-stream recycling systems is not the compositional variation among bottle brands but the level of non-glass contamination. This understanding can help improve the rates of glass waste reuse in container manufacturing, “demonstrating the value of keeping glass as part of a circular economy,” Gerace and Mauro conclude.

The open-access paper, published in International Journal of Ceramic Engineering & Science, is “Characterization of soda–lime silicate glass bottles to support recycling efforts” (DOI: 10.1002/ces2.10217).

Author

Lisa McDonald

CTT Categories

- Glass

- Manufacturing