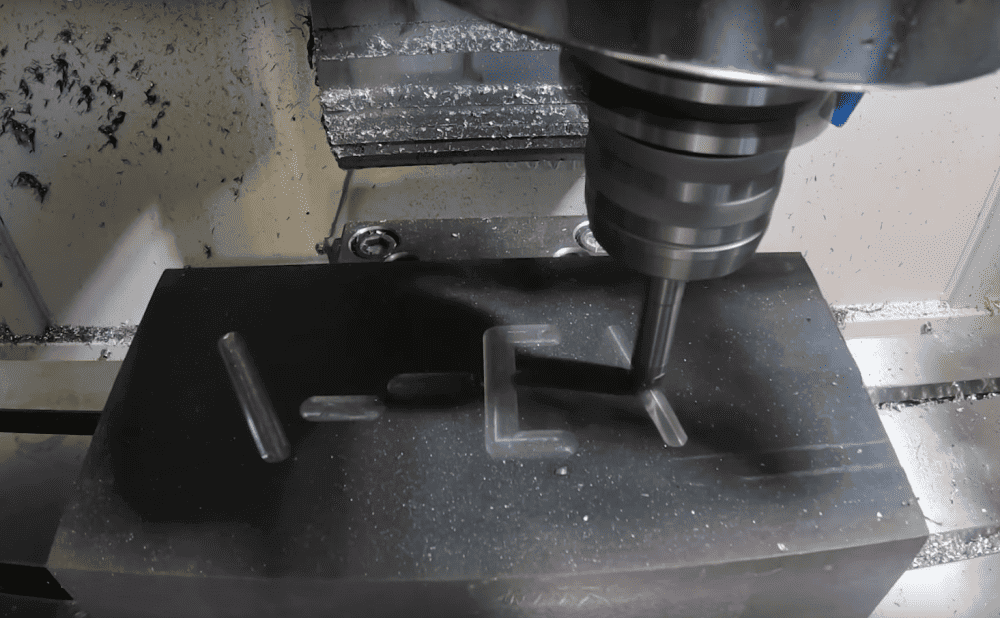

[Image above] Demonstration of the new Seco X-Head exchangeable cemented carbide milling heads. Researchers at Seco proposed a new model for predicting the thermal properties of cemented carbides. Credit: Seco Tools, YouTube

Though most details have since escaped my mind, I do remember studying diligently for the stage crew test in high school so I could become a certified member of the theater club.

Fortunately, passing the test meant receiving the almighty Backstage Handbook, an illustrated almanac of technical information. So even though I no longer can tell you all the types of knots and their uses, I can pull this book from my shelf and quickly refresh on the details.

The ability to quickly check a book or database for information on a given topic is a sometimes underappreciated ability in today’s world of internet search engines. But behind each reference set are researchers who poured their time and resources into confirming the information so that it can prove useful to others.

Today’s CTT spotlights the work of two researchers in Sweden, who just published a paper on the thermal properties of cemented carbides. The paper is a valuable resource for anyone debating which cutting tool will work best for their machining purposes.

The authors are Vitaliy Kazymyrovych and Vyacheslav Kryzhanivskyy, researchers at Seco Tools AB. The company, which is headquartered in Fagersta, Sweden, is part of Sandvik Machining Solutions, the tooling business area of the Sandvik Group.

In their paper, they note how, during metal cutting, temperatures up to 1,000°C can be generated at the interface between the cutting tool and the workpiece.

“Such high temperatures could lead to the degradation of tool material properties and, as a consequence, a premature wear or failure of the tool,” they write. “Naturally, a good thermal conductivity of the tool material, which allows rapid heat transfer from the cutting zone, is of great importance for the integrity of the tool during machining.”

Cemented carbides are the most common type of cutting tool materials. These metal matrix composites usually consist of tungsten carbide grains immersed in a cobalt binder, though researchers are exploring alternative materials to replace the cobalt.

The Steco researchers explain that several studies (such as here, here, and here) have investigated the thermal properties of cemented carbides. All agree that thermal conductivity increases with coarser tungsten carbide grain size and lower cobalt content.

Using this knowledge and several other parameters, the previous studies predicted thermal conductivity of cemented carbides with varying degrees of success. The Steco researchers suggest there are likely several reasons for the lower success rates, but the lack of reliable conductivity data is a main factor.

“The main weakness of the models that use conductivities of separate phases and their interfaces to estimate the overall material’s conductivity is the lack of reliable conductivity data for those components and dependence of that data on specific for each particular material factors, such as, for instance, content of other elements in [cobalt] phase or presence of grain growth inhibitors at the interfaces,” they write.

Additionally, the models rely on accurate determination of the average tungsten carbide grain size. Determining this information is not a trivial task because results depend heavily on the measurement method used and operator’s skills, for example.

Instead of relying on unreliable conductivity data or time-consuming grain size measurements, “in this study the emphasis is put on predicting thermal conductivity from reliable, readily available, or easily measurable material characteristics, such as chemical composition, coercivity, density, etc.,” the researchers write.

They selected 20 cemented carbide grades with a variety of tungsten carbide grain sizes and cobalt and cubic carbides content. Thermal properties were investigated by performing light (laser) flash analysis on flat circular samples using the Netzsch LFA 467 HT HyperFlash system.

For all investigated grades, thermal conductivity decreased with increased temperature, though the rate of decrease varied from grade to grade. Generally, conductivity of the samples with small tungsten carbide grain size and/or high cubic carbides content was less sensitive to the temperature.

Using this experimental data, the researchers formulated a set of regression equations based on reliable material parameters to predict thermal conductivity in the range of room temperature to 800°C. They achieved the most accurate predictions when the parameters formed a linear equation, with an average 4% difference between calculated and measured values.

They emphasize this accuracy was achieved using only the material’s chemical composition and coercivity.

“These [parameters] are usually readily available material data or could otherwise be determined with high precision,” they emphasize.

They caution that the predictions become less accurate for cemented carbides with cobalt content above 15 wt% and completely inaccurate at low temperatures for grades with nanosized tungsten carbide grains.

Regardless, “Reasonable correlation between measured and calculated conductivity was observed for most materials and temperatures,” they conclude.

The paper, published in International Journal of Refractory Metals and Hard Materials, is “Thermal properties of cemented carbides used for metal cutting” (DOI: 10.1016/j.ijrmhm.2022.106097).

Author

Lisa McDonald

CTT Categories

- Manufacturing

- Modeling & Simulation