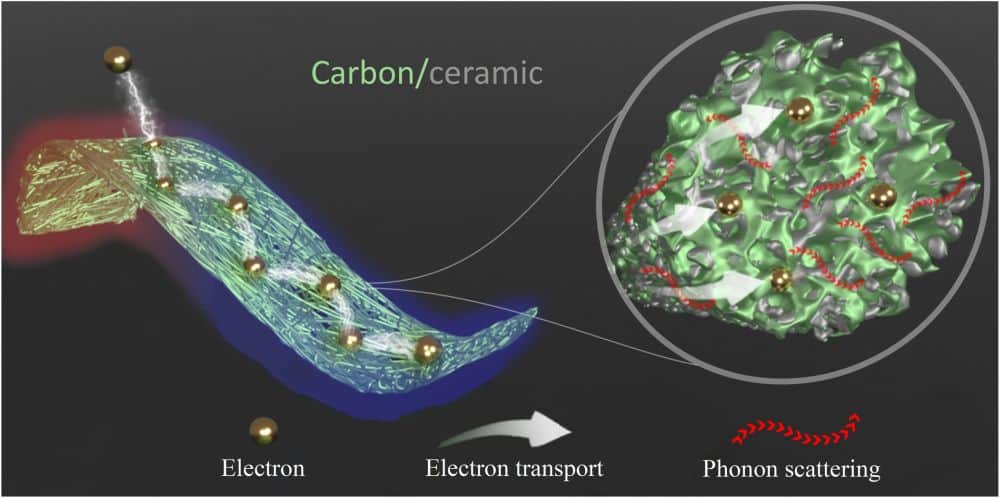

[Image above] Schematic of a flexible carbon/silicon nonwoven composite created at the University of Bayreuth that exhibits low thermal and high electrical conductivities. Credit: Liao et al., Science Advances (CC BY 4.0)

From interior decorators to software developers to mechanical engineers, all these professions share the same mantra—simple design is the best design.

Products based on simple designs are generally easier to understand, cheaper to make, and faster to fix than ones based on more complex designs. So, aiming for streamlined design is a goal for most designers.

Multifunctional materials are desirable building blocks for designers because they can serve several roles in a system, thereby reducing the number of necessary components. And thanks to advancements in fabrication and characterization techniques, designing materials with specific properties is more easily done than ever before.

In a recent open-access study, researchers at the University of Bayreuth in Germany demonstrated the truth of the above statement by fabricating a new multifunctional material using a readily industrialized production process.

The material they created is increasingly desired for new energy conversion and miniaturized electronic systems—it exhibits both extremely low thermal and high electrical conductivities.

Realizing such a capability is extremely difficult in metals. In metals, both electric current and heat transfer are primarily carried by electrons. Because both thermal and electrical conductivity are based on the same transport mechanism, they proportionally increase or decrease together as the temperature changes.

In contrast, ceramics primarily conduct heat through the transport of quantized atomic lattice vibrations called phonons. Because the conductivities are based primarily on different transport mechanisms, there is greater potential for realizing nonproportional values.

Some low-density porous carbon materials are known to exhibit low thermal conductivity and high electrical conductivity, but their thermal stability is not very good. This property limits their application in emerging high-temperature devices, such as solid oxide fuel cells.

In the new paper, the University of Bayreuth researchers overcame the thermal instability of carbon by combining it with a nanosized silicon-based ceramic. They created the flexible carbon/silicon nonwoven composite in three steps.

- Commercial polyacrylonitrile copolymer (PAN) and different amounts of oligosilazane (OSZ) were electrospun to create nonwoven fibers.

- The fibers were stabilized via a step-wise temperature program or by directly heating from 20° to 250°C under the air atmosphere.

- The stabilized fibers were then subjected to a carbonization/ceramization heat-treating process in an inert nitrogen atmosphere at 1,000°C for 1 hour, yielding the carbon/silicon nonwoven composite.

The carbon/silicon nonwoven composite featured a sea–island structure, in which the nanosized ceramic phase was homogeneously distributed alongside the carbon phase in every fiber.

The carbon phase modulated the electronic transport, while the ceramic phase induced phonon scattering. Together, these behaviors resulted in low thermal and high electrical conductivities.

In addition to low thermal and high electrical conductivities, the researchers showed that the carbon/silicon nonwoven composite is flame resistant and very thermally stable. Specifically, it withstood and maintained fiber form even in a 100% O2 atmosphere during limiting oxygen index tests.

During limited oxygen index tests, a pure carbon nonwoven material was easily ignited and burned out as the oxygen content went up to 80%, while the carbon/silicon nonwoven composite withstood and maintained the fiber form even in a 100% O2 atmosphere. Credit: Liao et al., Science Advances (CC BY 4.0)

“The unique multifunctional properties of this textile-like material combine the best properties of various material classes, such as polymer-foam rivaling thermal insulation, ceramic-like fire retardance and nonflammability, and high electric conductivity,” the researchers write.

The open-access paper, published in Science Advances, is “Extremely low thermal conductivity and high electrical conductivity of sustainable carbon–ceramic electrospun nonwoven materials” (DOI: 10.1126/sciadv.ade6066).

Author

Lisa McDonald

CTT Categories

- Material Innovations

- Thermal management