[Image above] Some people (and materials) make achieving extremes look easy, but the right technique can help others reach such levels as well. Credit: Great Big Story, YouTube

When I say “beach party,” what do you imagine? A cookout, some volleyball, a piña colada in hand? That sounds like a pretty nice, relaxing time. But if you’re like me, I immediately think of the one competition that is the bane of my existence at such parties—limbo.

Few people can achieve the limbo levels attained by Guinness World Record holder Shemika Campbell (I certainly cannot). However, if the right technique is used, many people can achieve lower levels than they previously thought possible—a concept that applies to materials as well.

For example, few materials are able to function properly in extremely thin layers like the 2D material graphene. The key to graphene and other 2D materials functioning at only a couple atoms of thickness is their anisotropic nature.

Anisotropic materials have different values when measured in different directions. For example, wood is stronger along the grain than across it. In the case of graphene and other 2D materials, in-plane bonding is significantly stronger than out-of-plane bonding, meaning bonds within a layer are stronger than bonds between layers. This fact makes it easy to pull a single layer from a bulk anisotropic material and have it retain desirable properties.

Most crystalline materials, though, are isotropic—they have the same strength in all directions. These materials therefore easily form as 3D objects because bonding in-plane and out-of-plane are equally strong, but trying to pull a single layer from the bulk material is hard.

For these crystalline materials to reach quasi-2D levels, a different technique must be used. Instead of pulling 2D layers from a bulk material, these materials are deposited as thin films on a substrate.

Perovskite oxides are one type of crystalline material that reaches quasi-2D levels through deposition. Scientists are interested in perovskite oxides because they display a wide assortment of potentially useful physical effects, including multiferroic behavior and magnetoresistance. Obtaining these properties in a monolayer format would open the door to new device possibilities.

Unfortunately, a previous study on perovskite oxides appeared to reveal a barrier to achieving 2D perovskites. Although the researchers could create ultrathin films of perovskite oxides, once removed from the substrate, the lattice structure collapsed if it was below a critical thickness.

While a lot can be gained through studying ultrathin perovskite layers on a substrate, certain properties, such as nanoscale elasticity, can only be studied in freestanding films.

So was the proposed critical limit as low as researchers could go to study freestanding films? According to a new study published in Nature, this limit does not appear to exist—you just need the right technique.

Unlike the study suggesting a critical limit, which used pulsed laser deposition (PLD), researchers from Nanjing University, the University of Nebraska–Lincoln, and the University of California, Irvine used molecular beam epitaxy (MBE) to create their perovskite oxide films.

In PLD, a laser beam evaporates and ionizes material from the surface of a target. The vaporized material then expands in a “plasma plume” and lands on a substrate. In contrast, an MBE process heats starting materials until they reach a sublimation point, and then the vaporized material is released to diffuse onto a substrate.

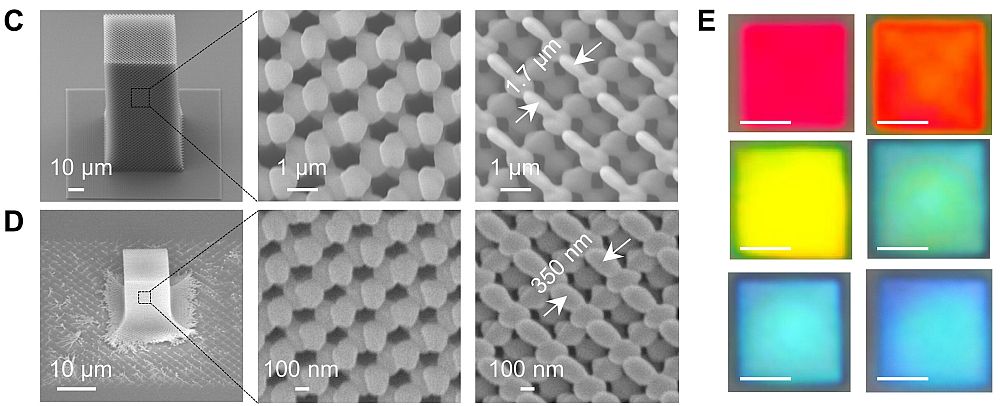

As a Nature News & Views article on the recent study explains, “The [researchers] used MBE to ‘spray paint’ ultrathin epitaxial layers of a perovskite and a water-soluble buffer layer onto a substrate, so that the buffer layer is sandwiched between the perovskite oxide and the substrate.” The researchers then dissolved the buffer layer with water and removed the freestanding perovskite oxide film, which they could then transfer onto a variety of other substrates.

The researchers demonstrated their method works on the perovskite oxides strontium titanate (SrTiO3) and bismuth ferrite (BiFeO3), but more studies will need to determine how broadly applicable the method is to other oxides. Also, now that one method has proved ultrathin freestanding perovskite oxides are possible, there may be other methods for making such films as well.

Just as research on 2D perovskite oxides benefitted from a new technique, maybe a different limbo method will help me achieve new lows!

The paper, published in Nature, is “Freestanding crystalline oxide perovskites down to the monolayer limit” (DOI: 10.1038/s41586-019-1255-7).

Author

Lisa McDonald

CTT Categories

- Nanomaterials