[Image above] Researchers at Indiana University–Purdue University Indianapolis showed titanium carbide MXene flakes undergo a phase transformation upon sintering to become a stable, bulk 3D crystal. Credit: Babak Anasori, Indiana University–Purdue University Indianapolis

From aerospace to energy storage, numerous fields desire advanced materials capable of operating at ultrahigh temperatures.

Usually, ultrahigh-temperature materials are created from early transition metal carbides, nitrides, and borides because of their high melting points (>3,000°C), high hardness, and good resistance to oxidation. However, like other ceramics, ultrahigh-temperature ceramics (UHTCs) can suffer from intrinsic brittleness.

To improve the strength and fracture toughness of UHTCs, researchers have explored using 2D materials as reinforcement because of their generally outstanding mechanical, electrical, and thermal properties. There are some studies using the popular 2D materials graphene and hexagonal boron nitride for this purpose, but another category of 2D materials may prove even more effective—MXenes.

MXenes are a family of 2D transition metal carbides, carbonitrides, and nitrides that are made by selectively etching MAX phases. Like their bulk carbide and nitride counterparts, MXenes are inherently considered UHTCs.

Titanium carbide (Ti3C2Tx) is the most studied layered carbide from the MXene family. It is known to have impressive material properties, including high in-plane mechanical stiffness (330 ± 30 GPa), high electrical conductivity (10,000–20,000 S·cm-1), and high temperature phase stability (up to 800°C under inert environments).

Recently, researchers have investigated using titanium carbide MXenes as additives in metal and ceramic matrix composites to endow the composites with improved in-matrix mechanical and electrical properties. However, this application faces a slight obstacle—these composites require processing at relatively high temperatures, and titanium carbide MXenes exhibit variable rates of oxidation and degradation when exposed to high temperatures in the presence of oxygen.

Technically, “all the ultrahigh-temperature ceramics (carbides, nitrides, and borides) get oxidized in air. But the oxide shell is too thin (at relatively low temperatures) that we don’t discuss them,” explains Babak Anasori, assistant professor at Indiana University–Purdue University Indianapolis, in an email. “But if we make UHTCs at 1-nm size [as is the case with MXenes], then oxidation becomes a major issue.”

Processing in low-oxygen environments offers a partial solution, but researchers still need to consider the possible effect of high temperatures on the MXene’s electrical, catalytic, and mechanical properties. In particular, early studies have established that titanium carbide MXenes undergo a three-stage phase transformation process from a 2D flake to a 3D crystalline structure when annealed at high temperatures:

- Low-temperature annealing up to 200°C results in loss of water molecules trapped between the MXene layers.

- Medium-temperature annealing causes desorption of functional groups. Specifically, temperatures of 300–500°C result in removal of –OH groups, –F groups desorb at 500–750°C, and complete desorption of all –F and –OH groups occurs above 800°C.

- High-temperature annealing above 800°C causes partial phase transformation to cubic TiCy, while full transformation occurs at temperatures above 1,200°C.

Processing at temperatures above 800°C is required for many metal and ceramic matrix composites, yet detailed characterization of the phase transformations at these temperatures is not complete. Fortunately, a new study published in Journal of Physics: Condensed Matter looks to fill this gap in knowledge.

The researchers come from Indiana University–Purdue University Indianapolis, School of Engineering and Technology. They are led by Anasori, who recently coedited a book on MXenes with Yury Gogotsi, Distinguished University and Charles T. And Ruth M. Bach Professor at Drexel University.

The researchers explain that titanium carbide MXenes offer a unique advantage compared to other 2D materials when it comes to investigating the material properties. “Fundamentally, Ti3C2Tx is a nano-lamellar titanium carbide, which means that Ti3C2Tx has compositional similarity to the bulk crystalline three-dimensional (3D) nano-lamellar transition metal carbides that have been studied for the past >50 years,” they write. As such, “We can use previously established literature on the bulk carbides as a guide on the potential phase transformation behavior of Ti3C2Tx during high-temperature annealing.”

Based on what is known about bulk carbides, the researchers hypothesized that titanium carbide MXenes would have two main ranges of phase transition:

- Low-temperature phase transition to a mix of 3D crystalline Ti2C + TiCy at temperatures of 700–1,000°C.

- High-temperature phase transition to purely TiCy at temperatures above 1,000°C.

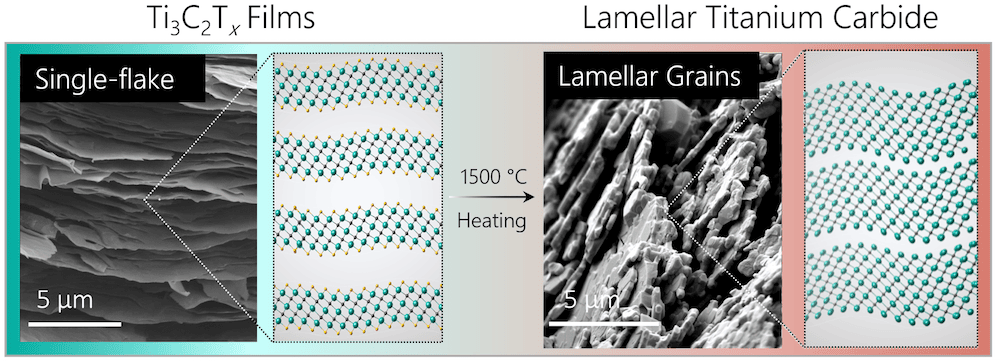

The researchers used wet chemical selective etching to synthesize two different forms of titanium carbide MXene films for their experiments: nondelaminated multilayer stacks (clay) and delaminated single-to-few layers of flakes (single-flake). Then, they investigated the phase transformations using in-situ heated X-ray diffraction paired with a 2D detector (up to 1,000°C) and ex-situ methods using tube furnace and spark plasma sintering for high-temperature annealing (up to 1,500°C).

The results confirmed their original hypothesis. In particular, they found that the titanium carbide MXene keeps its 2D layered structure up to 600°C, after which stable 3D crystalline phases of Ti2C and TiCy are formed. These phases remain stable up to annealing temperatures of 1,000°C in both single-flake films and multi-layer clay films, after which there is a subsequent transition to cubic TiCy above 1,000°C.

In an email, Ph.D. student Brian Wyatt explains why confirmation of this transition from a 2D to 3D crystalline phase is an important finding. Generally, the layers of 2D materials are held together by weak van der Waals forces. For 2D materials such as graphene or hexagonal boron nitride, the van der Waals bonds can become weak spots in the composites.

“In contrast, we can turn MXenes’ inter-flake van der Waals bonds to primary bonds through high-temperature sintering,” Wyatt says. This transformation will allow the MXene to “behave as a type of ‘glue’ within UHTCs to improve the bonding between ceramic grains, and thus form fracture and thermal shock resistance UHTCs with improved oxidation properties.”

Anasori’s group is already working on forming MXene UHTC composites using different ceramic materials and exploring their mechanical and oxidation properties. “We believe MXenes for the extreme environment will become a new and fast-growing research area,” Ph.D. student S. Kartik Nemani says in an email.

The paper, published in Journal of Physics: Condensed Matter, is “High-temperature stability and phase transformations of titanium carbide (Ti3C2Tx) MXene” (DOI: 10.1088/1361-648X/abe793).

Author

Lisa McDonald

CTT Categories

- Basic Science

- Nanomaterials

Related Posts

Sports-quality ice: From pond side to precision Olympic engineering

February 12, 2026