[Image above] Researchers in Japan grew a carbon nanotube forest of record length by combining aspects of previous research studies. Credit: Hisashi Sugime, Waseda University

If you are a fan of high-end vehicles, then you’re likely aware of the carbon fiber trend in recent years.

Carbon fiber is a strong, stiff, lightweight material composed almost exclusively of carbon atoms. When combined with other materials like plastic to form composites, these composites can replace steel in certain applications, such as the body panels of high-end cars.

As strong as carbon fibers are, however, there is another carbon-based material with even better tensile strength—carbon nanotubes.

Carbon nanotubes look somewhat like mini versions of carbon fibers—their average diameter of 0.4–40 nanometers is a thousand times smaller than the average 5–10-micrometer diameter of carbon fibers. However, the arrangement of carbon atoms within the nanotube structure is different from in fibers, which is why the nanotubes are so much stronger—they exhibit tensile strength between 100–200 GPa compared to the average 3–5 GPa for commercial carbon fibers.

If we could create and bundle together a lot of carbon nanotubes, we could theoretically produce a superbly strong material that may replace current carbon fibers. Unfortunately, accomplishing this task is extremely difficult in practice.

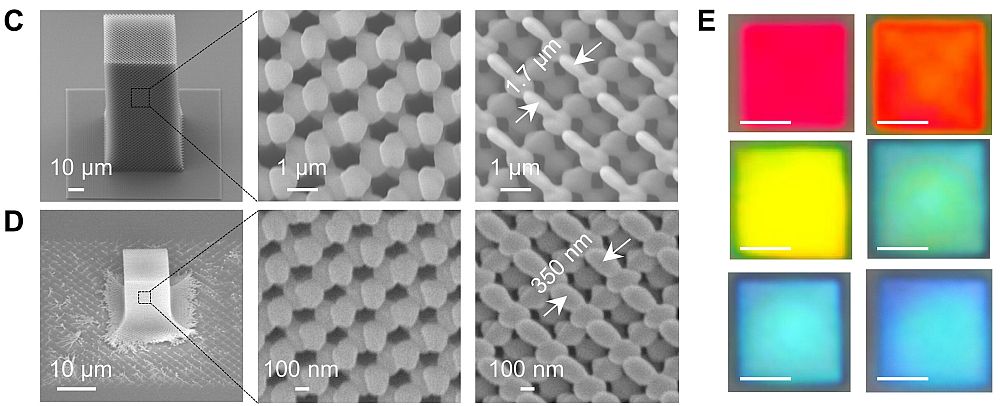

One factor hindering the realization of mass-produced carbon nanotube fibers is that there is a length limit when growing carbon nanotubes in groups. As I explained in an earlier CTT on this topic, carbon nanotubes are fabricated typically through chemical vapor deposition (CVD), a process that involves flowing gaseous carbon-containing molecules over a substrate containing catalytic particles. The catalysts decompose the carbon-containing gas, freeing carbon atoms to build up in vertical tubes.

Studies using the CVD method succeeded in growing individual carbon nanotubes about 50 cm in length. However, the maximum length of carbon nanotubes is drastically reduced to only a couple centimeters when the nanotubes are grown in arrays, or “forests.”

“To date, several groups have reported the growth of centimeter-scale [carbon nanotube] forests, and the maximum length that has been reached is ~2 cm using an iron-gadolinium (Fe-Gd) catalyst on an aluminum oxide (Al2O3) support. Nevertheless, with the conventional approaches, there seemed to exist a ceiling preventing growth beyond ~2 cm,” researchers write in a recent paper.

The researchers come from Waseda University and Shizuoka University in Japan. And in their study, they demonstrate a new method for carbon nanotube fabrication that breaks through the supposed group growth ceiling.

They explain that in the conventional CVD process, gradual structural changes in the catalyst cause growth to stop. In particular, Ostwald ripening and subsurface diffusion are seen as the main changes that terminate growth because they lead to depletion of active catalysts on the substrate surface.

“Therefore, it is essential to establish a method that alleviates these problems simultaneously, since even one factor can terminate the growth by deactivating the catalysts,” they write.

To address these problems, the researchers combined the following approaches they had researched in previous studies.

New catalyst featuring gadolinium

Based on their findings in a November 2019 paper, they added a gadolinium layer to the conventional iron-aluminum oxide catalyst coated onto a silicon substrate. “This [gadolinium] layer prevented the deterioration of the catalyst to a certain extent, allowing the forest to grow up to around 5 cm in length,” a Waseda University press release says.

Custom-made CVD chamber

To further prevent catalyst deterioration, they placed the catalyst-containing substrate in a custom-made CVD chamber that they initially reported on in a July 2012 paper.

They fixed the substrate to a pair of electrodes (tungsten wires) to apply voltage and quickly ramped up temperature of the substrate to 750°C by Joule heating with a direct current. Then they flowed a carbonaceous gas containing iron and aluminum ions over the substrate and waited.

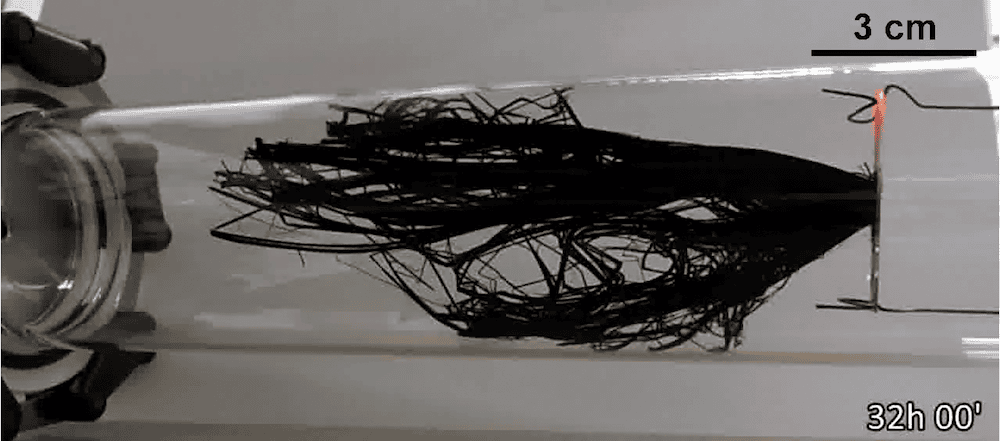

Growth behavior of the carbon nanotubes was recorded by taking pictures at 1-minute intervals using a digital camera. The above video compiles these images to demonstrate the growth. Credit: Hisashi Sugime, Waseda University

Over a growth lifetime of 26 hours, the carbon nanotube forest reached 14 cm in length, averaging a growth rate of 1.5 μm per second. Microscopy and spectroscopy observations of the carbon nanotubes at different growth periods show they are high-purity.

Tensile measurements revealed the carbon nanotubes demonstrate highest tensile strength at the top of the nanotube (nominally 0.54 GPa), which gradually decreases toward the bottom of the forest due to a drop in mass density of the nanotubes.

Though this strength may sound low compared to the more than 100 GPa achieved by single nanotubes, it is an expected result because “the larger numbers of [carbon nanotubes] in the specimens lead to the increase of the fatal defects, which resulted in lower strength and modulus,” the researchers explain in the paper.

In the press release, lead author and assistant professor at Waseda University Hisashi Sugime says the development of this fabrication process will benefit more than just researchers who study carbon nanotubes.

“This simple but novel method that drastically prolongs catalyst lifetime by supplying ppm-level vapor sources is insightful for catalyst engineering in other fields such as petrochemistry and nanomaterial crystal growth,” he says. “The knowledge herein could be pivotal to making nanomaterials a ubiquitous reality.”

The paper, published in Carbon, is “Ultra-long carbon nanotube forest via in situ supplements of iron and aluminum vapor sources” (DOI: 10.1016/j.carbon.2020.10.066).

Author

Lisa McDonald

CTT Categories

- Nanomaterials