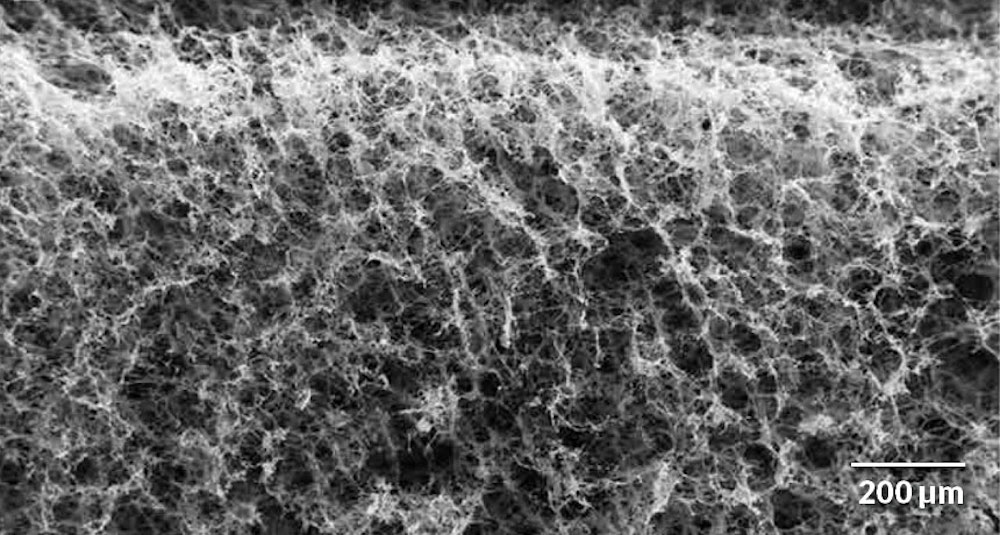

[Image above] Many materials become brittle at cold temperatures, but researchers from Nankai and Rice universities found their 3D cross-linked graphene foam retained its elasticity at temperatures near absolute zero. Credit: Kai Zhao et al., Science Advances 5(4), 2019 (CC BY-NC 4.0)

A staple of almost any science demo is ice cream—liquid nitrogen ice cream, that is.

At -196°C (-320°F), liquid nitrogen is an extremely cold substance. When it comes into contact with cream, it causes the water and fat particles to rapidly freeze and remain small, resulting in ice cream with a very creamy texture.

While ice cream is definitely the yummiest way to demonstrate liquid nitrogen’s freezing abilities (be careful when eating it though!), another liquid nitrogen demo shows how cold affects objects in a more dramatic manner—submerging a racquetball in liquid nitrogen. A racquetball, being made of rubber, is quite bouncy, but after being doused in liquid nitrogen, it becomes brittle and shatters.

Liquid nitrogen ice cream is a yummy demonstration of how exposing materials to extreme cold can change their physical properties. Credit: Rosanna Pansino, YouTube

This tendency to become brittle when exposed to extreme cold is not unique to rubber (think of all the yearly winter articles warning about burst pipes). Of course, materials do exist that can handle frigid temperatures without breaking, but elasticity and ductility are generally compromised at these lowered temperatures.

Materials that can respond elastically to a force at low temperatures are needed in many industries, from aerospace to medical to oil and gas. One group of materials that has been suggested for these applications is carbon nanomaterials.

“Carbon nanomaterials, such as carbon nanotube (CNT) and graphene, have been thought as suitable building blocks for making temperature-invariant elastic materials because of their extraordinary mechanical properties, flexibility, and exceptional thermal stability,” researchers explain in a recent paper. “However, it has been a great challenge to realize these intrinsic properties in the bulk material scale, because restacking and/or agglomeration of nano-individuals (graphene sheets or nanotubes) severely diminish or weaken most of their intrinsic properties.”

The researchers, led by professors Yongsheng Chen of Nankai University and Pulickel M. Ajayan of Rice University, note that previous studies have demonstrated 3D graphene materials can retain their ability for large and reversible deformation in liquid nitrogen. However, studies for these mechanical properties at deep cryogenic temperatures, i.e., in liquid helium (-270°C, or just above absolute zero), have not been conducted.

“[A]lmost all materials would behave quite differently and, in some cases, might demonstrate unexpected properties at deep cryogenic temperatures, as compared to that at [room temperature] or even at liquid nitrogen temperature,” the researchers explain in their paper. “Therefore, studies for the properties (including mechanics) at such deep cryogenic temperatures should be important, and some unexpected properties might be observed.”

So, using a 3D cross-linked graphene foam they had previously developed, the researchers investigated the mechanical properties of graphene foam in liquid helium using a homemade in situ large-strain mechanical analysis system. Their system could continuously monitor material deformations from “deep cryogenic temperature at 4 K [-270°C] to a high temperature of 1,273 K [1,000°C]” without breaking the vacuum seal.

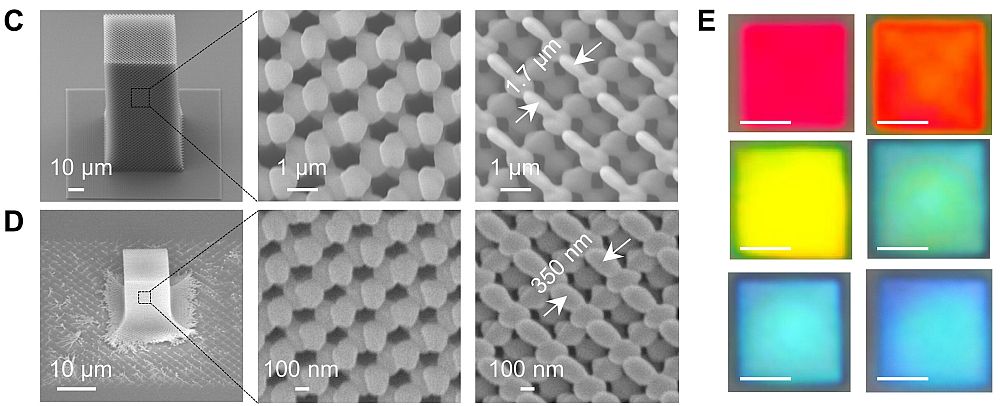

The researchers’ 3D graphene foam retained its elasticity at temperatures near absolute zero thanks to its unique cross-linked graphene network architecture. Credit: Kai Zhao et al., Science Advances 5(4), 2019 (CC BY-NC 4.0; located in supplementary materials)

Their results are impressive—there were almost no differences in mechanical properties between graphene foam in liquid helium compared to room temperature, including nearly fully reversible superelastic behavior of up to 90 percent strain (after being compressed to one-tenth its original thickness), unchanged Young’s modulus, near-zero Poisson’s ratio, and great cycle stability.

“These unique behaviors have never been reported for any other material,” the researchers state.

In their study, the researchers compared experimental results with simulated reactions to determine that these unprecedented behaviors are due to the foam’s unique cross-linked graphene network architecture and graphene’s temperature-independent mechanical properties.

In the future, the researchers say that if similar bulk materials could be made from other 2D materials using the same assembly strategy, then “some unexpected and fascinating properties, not only the mechanical aspect, might be discovered.”

Now that it is possible to grow large-area single-crystal domains of borophene, maybe it will be the next 2D material to test!

The open-access paper, published in Science Advances, is “Super-elasticity of three-dimensionally cross-linked graphene materials all the way to deep cryogenic temperatures” (DOI: 10.1126/sciadv.aav2589).

Author

Lisa McDonald

CTT Categories

- Material Innovations

- Nanomaterials