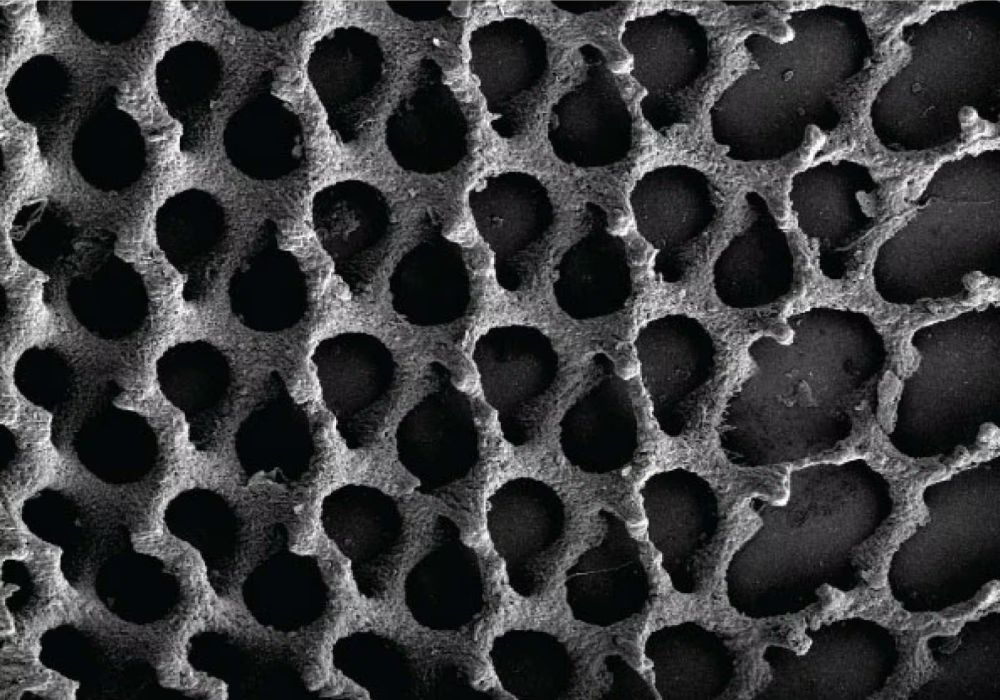

[Image above] This scanning electron micrograph shows the silica-based nanocapsules formed after removing gold nanoparticles and polystyrene beads, leaving behind an opening that can be used to fill the capsules with a payload. Credit: Jichuan Qiu, Georgia Tech

When my friend was preparing this summer for a big cross-country move for university, the biggest thing on their mind was not what classes they would take nor what Greek organization they would join. It was instead how they would move all their things there.

My friend does not have a car, and so I helped them research the cost of various moving options, from mailing things through a freight service to renting a U-Haul. Each method of delivering their items to university came with pros and cons, and at times made me wish transporters were real.

Doctors regularly make decisions about delivery methods as well, but instead of moving furniture, what they often move are drugs into a person’s body to treat illness and disease.

One challenge doctors face in drug delivery is how to deliver the drug directly to where it is needed in the body, rather than dispersing it throughout the whole system. Phase change materials (PCMs) are a potential solution to that challenge.

PCMs are substances that absorb and release thermal energy (heat) during the process of changing phase, such as going from solid to liquid (melting) or liquid to solid (solidifying). PCMs have received attention in recent years because of the materials’ ability to serve as a temperature-controlled “smart matrix.” Drugs and other payloads trapped within a solid PCM can be quickly released when the PCM melts in response to increased temperature.

Natural fatty acids are an attractive PCM for drug dispersal because of their biocompatibility and biodegradability, diversity, abundance, and low cost. However, nanoparticles made from fatty acids tend to aggregate into larger particles and float on the surface of aqueous solutions, and they often pre-degrade in vivo, leaking the drugs before reaching a target destination.

These challenges can be addressed by encapsulating the drug-containing fatty acids in a nanoscale carrier, which protects the PCM from bodily fluids until it has reached its destination. Finding a good material for the nanoscale carrier, though, is an ongoing research question.

In June, researchers from the Georgia Institute of Technology and Shandong University in China published a paper in Angewandte Chemie describing a way to effectively deliver drug-containing fatty acids into the body.

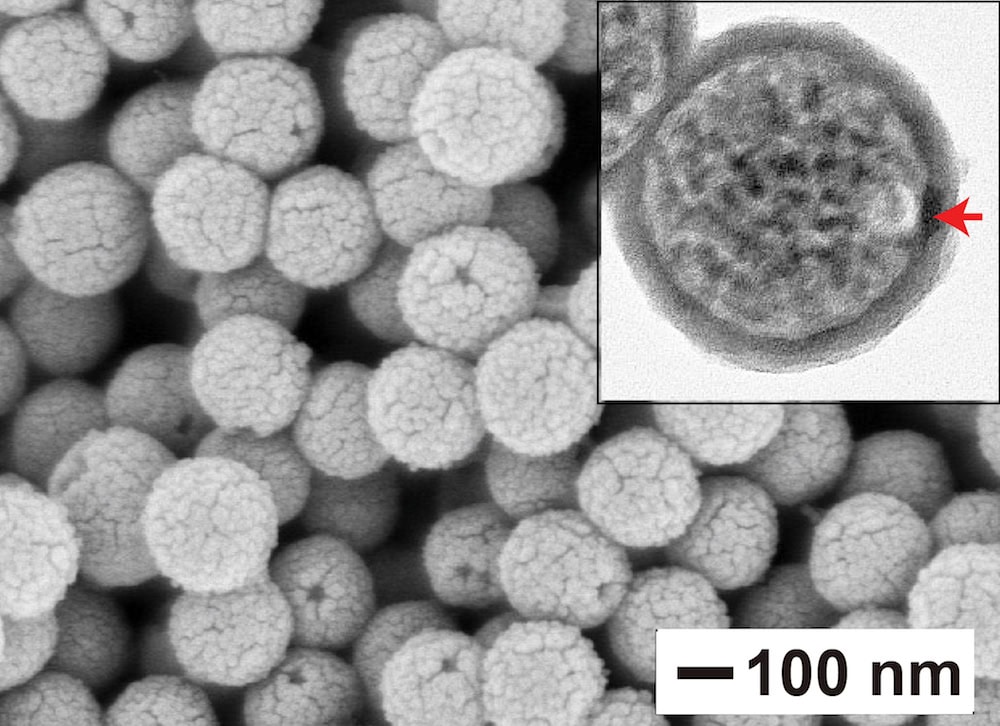

For their study, the researchers tested the efficacy of silica-based nanocapsules as a carrier for fatty acids. To create the nanocapsules, the researchers first fabricated spheres out of polystyrene with a small gold nanoparticle embedded in its surface. They then coated the spheres with a silica-based material everywhere except where the gold nanoparticle was embedded. After removing the gold and polystyrene, only a hollow silica sphere with a small opening remained.

The researchers loaded the nanocapsules with a mixture of fatty acids, a near-infrared dye, and an anticancer drug. They then placed the nanocapsules in water and used a near-infrared laser to heat the dye while tracking concentration of the released therapeutic.

“The test confirmed that without the use of the laser, the medicine remains encapsulated. After several minutes of heating, concentrations of the therapeutic rose in the water,” a Georgia Tech press release states.

In the release, Jichuan Qiu, a postdoctoral fellow at Georgia Tech, explains the usefulness of their finding. “This controlled release system enables us to deal with the adverse impacts associated with most chemotherapeutics by only releasing the drug at a dosage above the toxic level inside the diseased site,” he says.

The paper, published in Angewandte Chemie, is “Encapsulation of a phase-change material in nanocapsules with a well-defined hole in the wall for the controlled release of drugs” (DOI: 10.1002/anie.201904549).

Author

Lisa McDonald

CTT Categories

- Biomaterials & Medical