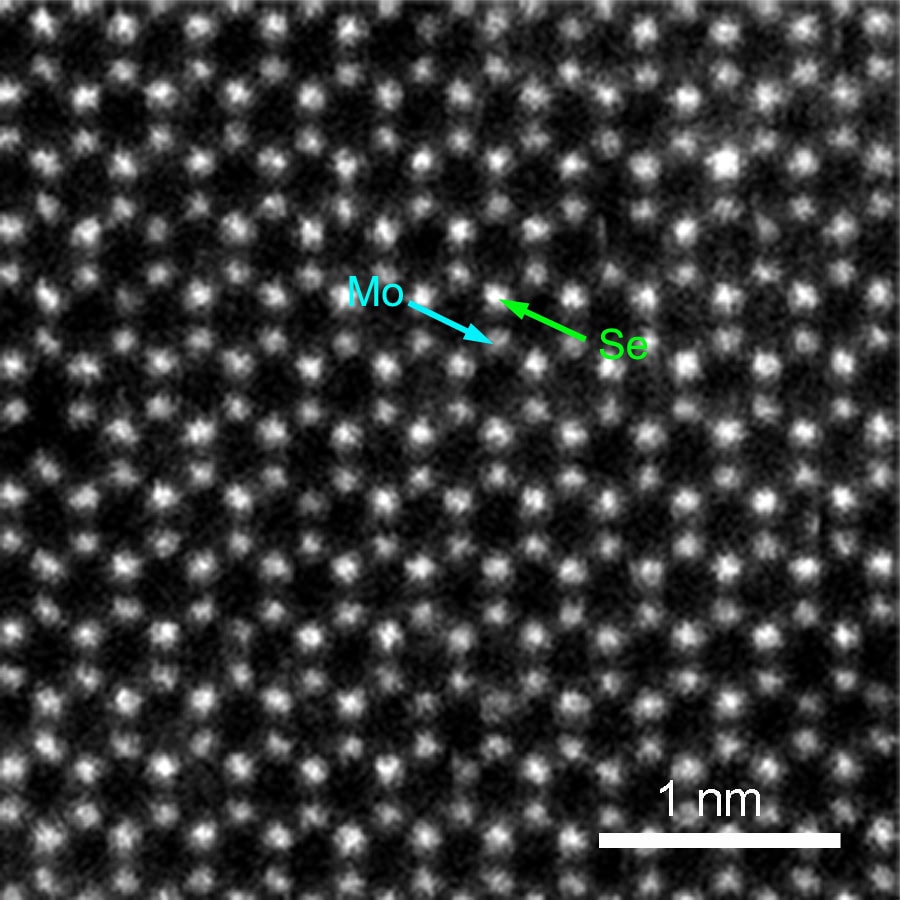

[Image above] When seen from above, the atoms in 2-D molybdenum diselenide resemble a hexagonal grid, like graphene. But in reality, the darker molybdenum atoms are sandwiched between top and bottom layers of selenide atoms. Rice University researchers tested the material for its tensile strength. Credit: Lou Group; Rice University

When it comes to developing next-generation flexible electronics, researchers see major potential in 2-D materials to help us get there.

The time-to-market gap for commercially viable graphene keeps shrinking, with promising new developments every day that aim to manufacture graphene to produce faster, higher-performing, more efficient electronics and other applications.

And graphene has a lot going for it.

The material’s single-layer thickness, toughness, and mechanical and thermal properties make it an ideal choice for developing electronic, optoelectronic, and electromechanical devices and sensors.

It also effectively teams up with glass to boost electronic properties; it’s a metal that behaves like water; and it can interact safely with brain neurons, which broadens the material’s biomedical applications.

Another promising 2-D material for use in future electronics, molybdenum diselenide, has been considered alongside graphene for use in flexible electronics and next-generation optical devices.

But can it hold up under strain?

Researchers at Rice University (Houston, Texas) recently found that 2-D semiconducting molybdenum diselenide’s tensile strength is more brittle than expected, due to the material’s inherent flaws—as small as one missing atom can crack the material under strain, according to a university press release.

Jun Lou, materials scientist at Rice who led the study, says this finding could cause the industry to take a more scrupulous look at the properties of 2-D materials before incorporating them into new technologies.

“It turns out not all 2-D crystals are equal,” Lou says in the release. “Graphene is a lot more robust compared with some of the others we’re dealing with right now, like this molybdenum diselenide. We think it has something to do with defects inherent to these materials.”

And because defects can be a single atomic vacancy in the crystalline structure, “It’s very hard to detect them,” Lou adds. “Even if a cluster of vacancies makes a bigger hole, it’s difficult to find using any technique. It might be possible to see them with a transmission electron microscope, but that would be so labor-intensive that it wouldn’t be useful.”

A nanomechanical device designed by Rice University scientists is used to measure the strength of 2-D nanomaterials like molybdenum diselenide, the subject of a recent Rice study that found it far more brittle than graphene. Credit: Lou Group; Rice University

Molybdenum diselenide is a semiconducting material with a hexagonal array similar to graphene, but it’s actually a sandwich of metallic atoms between two layers of chalcogen atoms (selenium, in this study), the release explains. Researchers are testing the material’s effectiveness in transistors and technologies like next-generation solar cells and electronic and optical devices.

Lou and his team “measured the material’s elastic modulus, the amount of stretching a material can handle and still return to its initial state, at 177.2 (±9.3) gigapascals,” the release explains. The found that graphene is more than five times as elastic than molybdenum diselenide. Its fracture strength, the amount of stretching a material can handle before breaking, was measured at 4.8 (±2.9) gigapascals. Graphene is nearly 25 times stronger, the team says.

Watch molybdenum diselenide crack under pressure in the short video below.

Credit: Rice University; YouTube

“The important message of this work is the brittle nature of these materials,” Lou says. “A lot of people are thinking about using 2-D crystals because they’re inherently thin. They’re thinking about flexible electronics because they are semiconductors and their theoretical elastic strength should be very high. … But in reality, because of the inherent defects, you rarely can achieve that much strength.”

The study, published in Advanced Materials, is “Brittle fracture of 2D MoSe2” (DOI: 10.1002/adma.201604201).

Author

Stephanie Liverani

CTT Categories

- Electronics

- Manufacturing

- Material Innovations

- Nanomaterials