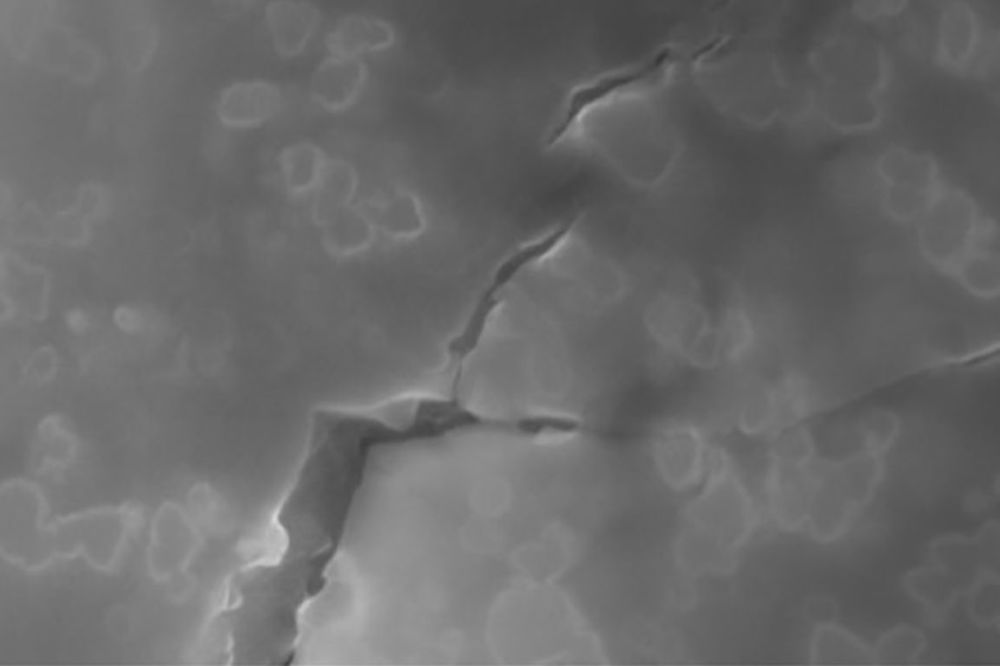

[Image above] An electron micrograph of a new, tougher glass developed at the University of California, Los Angeles, showing how nanoparticles (rounded, irregular shapes) deflect a crack and force it to branch out. Credit: SciFacturing Lab, UCLA

What has high transparency, low thermal conductivity, and is prone to break?

If you guessed oxide glasses, you would be right!

The inherent brittleness of oxide glasses is a well-known fact, and one that scientists are actively trying to circumvent. Many researchers have successfully used external treatments like chemical coatings to reduce brittleness, but these treatments can be costly and mainly protect against fracture rather than change the inherent brittleness of the glass.

Creating intrinsically crack-resistant oxide glasses would be ideal, and a recent CTT post looked at how researchers from Denmark and the United States increased an oxide glass’s microductility by hydrating the atomic network. Now, researchers from the University of California, Los Angeles, have presented another way to increase an oxide glass’s crack resistance—by infusing the glass with nanoparticles.

“While nanoelements may be added into glasses and ceramics to form nanocomposites with enhanced properties, it is extremely difficult to distribute and disperse them inside the liquid glass/ceramic matrix in traditional processing methods,” the researchers write in the paper.

However, nanoparticles have been successfully dispersed in molten metals before, so the researchers decided to see if this method worked for molten glasses as well.

They added silicon carbide nanoparticles into molten glass made from cordierite (2MgO•2Al2O3•5SiO2) and B2O3 at 1,650°C (3,000°F). This process caused the nanoparticles to evenly disperse.

The researchers attribute the resultant stabilization mechanism to three major factors:

- Energy barrier due to the wettability between nanoparticles and ceramic melt

- Attractive van der Waals potential between nanoparticles in the melt

- Thermal energy (kT)

When tested, samples with 30 vol% SiC nanoparticles (SC-30 samples) showed fracture toughness of 6.66 MPa m1/2, which is about five times higher than glass without SiC nanoparticles. The researchers say the nanoparticles act as roadblocks to potential fractures, forcing fractures to branch out into tiny networks rather than taking a straight path.

The SC-30 samples also showed a stress-modulus relationship close to E/14, which is close to the theoretical value of E/10. This value is far closer to the theoretical limit than many other inorganic glasses, single crystal ceramics, and nanocrystalline ceramics reported so far. For example, single crystal silicon nitride is around E/32, and nanocrystalline boron carbide is around E/30.

A UCLA press release notes that the glass used in the experiment was somewhat milky rather than clear. However, Xiaochun Li, principal investigator and professor of materials science and engineering at UCLA, says the process could be adapted to create clear glass.

The paper, published in Advanced Materials, is “Strong and tough glass with self-dispersed nanoparticles via solidification” (DOI: 10.1002/adma.201901803).

Author

Lisa McDonald

CTT Categories

- Glass

- Nanomaterials