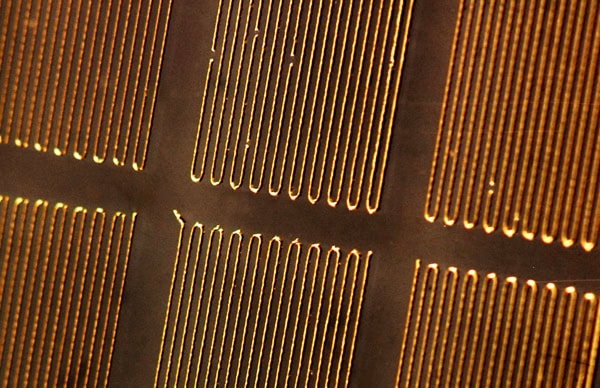

Purdue researchers have developed a technique to produce machines made of elastic materials and liquid metals by embedding a liquid-alloy pattern inside a rubber-like polymer to form a network of sensors. Credit: Rebecca Kramer; Purdue University

We’ve previously established that elasticity is a benefit to pants, but it’s also proven to be vital to the advancement of everything from robots to electronics.

(Just don’t try to have those robots care for grandma, because we’ve also determined that while we’re generally okay with scientific advances, Americans just aren’t cool with letting these small wonders care for the elderly.)

Though such flexibility would be critical in (as-yet-to-be-realized) sensory-skinned robots and garments that allow the wearer to interact with their PC, there isn’t a practical way to manufacture these “soft machines”—at least, there wasn’t, until now.

Led by Rebecca Kramer, researchers at Purdue University have developed a new manufacturing technique that will help make the commercial production of machines made of elastic materials and liquid metals more practical.

According to a Purdue news release, by using a 3D printer to create strain gauges—devices that measure how far a material will stretch—“the researchers embedded liquid-alloy devices into a rubber-like polymer called polydimethylsiloxane, or PDMS, a silicon-based ‘elastomer.’ The liquid gallium-indium alloy was used to create patterns of lines to form a network of sensors.”

“It has some odd properties,” says Kramer, assistant professor of mechanical engineering. “Gallium oxidizes really quickly and forms a thick gallium-oxide skin, which is challenging to work with using typical liquid-processing techniques.”

But just as celebrities like Cindy Crawford have transformed blemish to beauty, rather than cower in the face of the alloy’s oxidized skin, the team developed a manufacturing method that capitalizes on it.

“We exploit this oxide skin by using it for structural stability. This means you can print liquid on a surface and it will maintain stable structures without moving around,” she says. “Once you print it you can flip it over or turn it on its side, because the liquid is encased by this oxide skin. We use this finding to embed our electronics in elastomer without ruining or altering the printed structures during the processing steps.”

Conventional strain gauges made of metal film are rigid and break after reaching about 1-percent deformation. Not so with the soft strain gauges, which stretch right alongside the material, measuring 100 percent of its strain.

Kramer notes that the soft strain gauge can measure just about any material—including the skin that surrounds our joints, which means it could find immediate application in the development of soft and stretchable wearable technology that needs to bend and give with elbows, knees, and wrists.

She adds, “If you want to achieve a strain gauge device and you want the traces to be a certain width or height, we can tell you with our paper exactly what parameters you should choose, including the flow rate of the liquid, the speed of the stage, and the standoff distance of the nozzle from the substrate. We have created a design strategy for 3D printing liquid metals.”

Their findings, published in Advanced Functional Materials, show that unlike the liquid alloy, the oxide skin adheres easily to the PDMS.

“Most sensors made from these materials are prototyped individually and limited to the millimeter-scale,” Kramer says in the release. “Our process enables digital fabrication of the sensors on the micro-scale. While this is a huge step forward, we need to continue to decrease scale and increase density to develop sensors and electronics that are comparable to traditional, rigid devices and that mimic the functionality of human skin.”

The team, which also includes postdoctoral research associate J. William Boley, doctoral student Edward L. White, professor of mechanical engineering George T.C. Chiu, believes the process could be used not only in the production of soft machines, but also in producing pressure sensors, capacitors, and conductors.

The paper is “Direct Writing of Gallium-Indium Alloy for Stretchable Electronics,” (DOI: 10.1002/adfm.201303220).

Author

Jessica McMathis

CTT Categories

- Basic Science

- Manufacturing