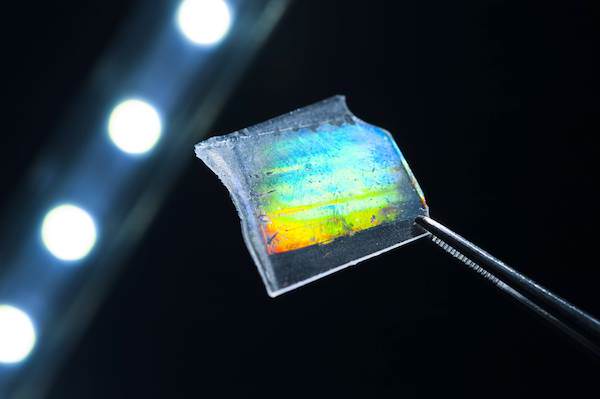

[Image above] Glassomer can be milled, turned, lasered, or processed in CNC machines – just like a conventional polymer Credit: Markus Breig, KIT

Glass is one of those unique materials that has been the subject of much discussion in the glass science commnity.

I mean, in what other scientific disciplines can you find experts who are still passionately debating their favorite material?

Glass research has advanced to the point where glass material can now be 3-D printed. Last year, scientists at Karlsruhe Institute of Technology (KIT) demonstrated 3-D printing of glass components using stereolithography with silica nanocomposite ink.

And earlier this year, researchers from Lawrence Livermore National Laboratory printed small glass pieces made from silica and silica-titania inks.

Now, KIT scientists have taken their glass research a step further. Head of the NeptunLab interdisciplinary research group of KIT’s Institute of Microstructure Technology Bastian Rapp and his research team have developed a process for fabricating pure quartz glass that opens up possibilities for industrial use.

“It has always been a big challenge to combine highly pure quartz glass and its excellent properties with a simple structuring technology,” Rapp says in a KIT news release.

“Glasses, and especially high-purity fused silica glasses are extremely difficult to structure,” team member Dorothea Helmer states in an Advanced Materials video.

Rapp and his research team actually created a hybrid of sorts, by mixing glass with a polymer to fabricate a solid silica nanocomposite. Called (what else?) “Glassomer,” the new material offers the strength of glass while behaving like a polymer.

The researchers mixed quartz glass particles 40 nm in size with a liquid polymer, forming a consistency similar to sponge cake, according to the release. Next, they solidified it using heat and light exposure, resulting in a 60/40 ratio of glass and polymer. The polymers bond the glass to maintain its shape—which makes it a perfect consistency to form highly-detailed objects.

Glassomer can be processed in machines “just like a conventional polymer” the release states, enabling smaller, more intricate and detailed structures to be produced. Rapp’s team fabricated small nuts, bolts, and diffractive optical elements.

For highly pure quartz glass structures, the researchers have to remove the polymer by heating it to between 500–600oC (932–1,112oF) and then sintering at 1,300oC (2,372oF). The researchers state that Glassomer can be “milled, turned, laser-machined, or processed in CNC machines just like a conventional polymer.”

The researchers’ technology makes pure glass material suitable for applications in the optical, biotech, microelectronics, and medical engineering industries.

“Our process is suited for mass production,” Rapp adds in the release. “Production and use of quartz glass are much cheaper, more sustainable, and more energy-efficient than those of a special polymer.”

The paper, published in Advanced Materials, is “Glassomer—Processing Fused Silica Glass Like a Polymer” (DOI: 10.1002/adma.201707100).

Watch the video below to learn more about the process.

Want to read more articles like this? Subscribe to the Ceramic Tech Today newsletter to continue to receive the latest news in the ceramic and glass industry right in your inbox! Visit this link to get started.

Author

Faye Oney

CTT Categories

- Basic Science

- Biomaterials & Medical

- Environment

- Glass

- Manufacturing

- Material Innovations

- Nanomaterials

- Optics