[Image above] A new laser-based synthesis process could enable scalable, energy-efficient manufacturing of ultrahigh-temperature ceramics for aerospace applications. Credit: Yuri Hoyda, Shutterstock

Just like their intended aerospace applications, the development of ultrahigh-temperature ceramics (UHTCs) has raced ahead in recent years at high speeds.

UHTCs are a class of materials comprised of borides, carbides, and nitrides of transition metals with very high melting points, generally above 2,000°C. Some of these materials already have established industrial uses, such as electronic components and cutting tool additives. But research on UHTC borides and carbides with melting points above 3,000°C is growing due to their potential use as leading edges, nose caps, and other high-stress parts in hypersonic aircraft and shuttles.

In general, there are two methods employed for the commercial processing of UHTC powders: solid-state reactions and thin film deposition. Solid-state reactions are an effective way to produce a large quantity of UHTC powders, but achieving high purity can be difficult due to incomplete reactions. On the other hand, thin film deposition can produce UHTC powders with very high purity, but this process is more expensive and not meant for large-scale production.

A scalable manufacturing method that produces high-quality powders is needed to facilitate the widespread adoption of UHTCs in the aerospace industry. Such a method may now exist thanks to some innovative work out of North Carolina State University.

The new method, which is described in an open-access paper, was developed by NC State professors Cheryl Xu and Tiegang Fang, as well as postdoctoral researcher Shalini Rajpoot and Ph.D. student Kaushik Nonavinakere Vinod. It involves using a laser as the heat source in polymer-derived ceramics (PDC) processing.

PDC processing is a well-established technique for producing ceramics that are conventionally very difficult to shape, such as silicon carbide. It involves the conversion of preceramic polymers into solid ceramics through pyrolysis, i.e., thermal decomposition of the polymer, which leaves behind ceramic materials that can be further densified through sintering.

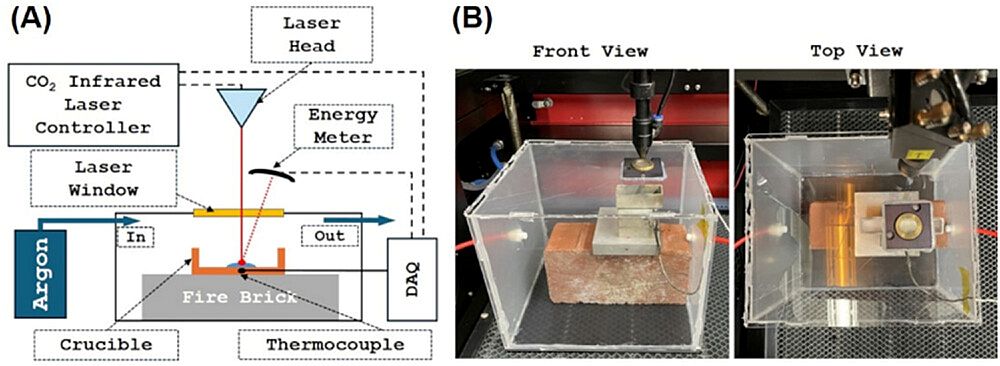

Traditionally, pyrolysis of the preceramic polymer takes place in a hot furnace with an inert atmosphere. But pyrolysis can also be triggered by lasers, which allow for faster and more controlled heating.

The laser-based PDC approach proposed by the NC State researchers uses a 120-watt CO2 laser to create localized heating above 2,000°C in roughly 30 seconds. Full conversion of the preceramic polymer into a solid ceramic occurs in under 5 minutes.

What makes this laser-based PDC processing method unique is that it combines both pyrolysis and cross-linking into a single step. Usually in PDC processing, before pyrolysis occurs, the preceramic polymer undergoes light- or thermal-based curing to link the material’s polymer chains and enhance its structural integrity. In the NC State process, however, the laser is applied to the surface of a liquid preceramic polymer, causing it to crosslink and immediately undergo pyrolysis in essentially a one-step process.

A) Schematic illustration of the laser-based PDC processing setup, showing the CO2 laser system, environmental chamber, argon gas flow, and data acquisition components. B) Photos of the experimental setup, displaying the front and top views of the environmental chamber. Credit: Rajpoot et al., Journal of the American Ceramic Society (CC BY 4.0)

The researchers used this process to successfully synthesize phase-pure hafnium carbide (sub-40 nm grain size), which has the highest melting temperature of any UHTC. The maximum yield of preceramic polymers to hafnium carbide was 54%, which is 18% higher than the yield reported for a furnace-based PDC process.

Taking this process a step further, the researchers used the laser-based PDC method to create hafnium carbide coatings on carbon-fiber-reinforced carbon composites. The coatings demonstrated strong adhesion, uniform coverage, and potential as a thermal- and oxidation-resistant layer, all beneficial properties for aerospace applications.

“We are excited about this advance in ceramics and are open to working with public and private partners to transition this technology for use in practical applications,” says Xu in a press release.

In an email, Xu says they are beginning to explore the creation of compositionally graded structures with this method by spatially varying the preceramic polymer.

The open-access paper, published in Journal of the American Ceramic Society, is “Synthesis of hafnium carbide (HfC) via one-step selective laser reaction pyrolysis from liquid polymer precursor” (DOI: 10.1111/jace.20650).

Author

Lisa McDonald

CTT Categories

- Manufacturing

- Thermal management