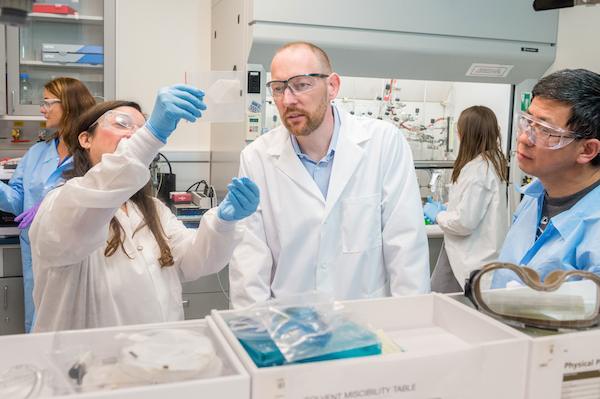

[Image above] Argonne’s Tijana Rajh explains recently synthesized metal oxide nanoparticle samples with controlled amounts of structural defects to NDW Director Andreas Roelofs and fellow researcher Xiao-Min Lin. Also pictured are Argonne researchers Elena Rozhkova (left) and Elena Shevchenko. Credit: Argonne National Lab

The U.S. national labs attract some of the top scientific talent to solve some of the biggest challenges. Those 17 labs, run by the Department of Energy, house some of the best and most advanced scientific instrumentation and techniques available, thanks to a hefty budget that annually surpasses $11 billion.

Argonne National Lab in Argonne, Ill., is no exception—its grounds house the Advanced Photon Source, a huge supercomputing facility, a superconducting linear accelerator, and much more.

The equipment, setup, or extensive use of those advanced instruments is often so expensive that it is not feasible for many organizations to purchase them independently. And yet the information that those techniques provide can be critical to develop new disruptive products for the market—like brand new batteries, next-gen solar cells, or revolutionary materials.

“Recognizing the power of these technologies and seeking to accelerate their impact, the U.S. DOE’s Argonne National Laboratory has created two new collaborative centers that provide an innovative pathway for business and industry to access Argonne’s unparalleled scientific resources to address the nation’s energy and national security needs,” according to a recent ANL press release. “These centers will help speed discoveries to market to ensure U.S. industry maintains a lead in this global technology race.”

The collaborative centers focus on two broad areas of research with high potential to impact new products and developments. ANL’s new Nano Design Works (NDW) will enable collaboration with business partners focusing on nanotechnology R&D. And the Argonne Collaborative Center for Energy Storage Science (ACCESS) will pinpoint advances in energy storage technologies.

Hear more about each center in these short videos from ANL.

Credit: Argonne National Laboratory; YouTube

Credit: Argonne National Laboratory; YouTube

The centers will foster bidirectional collaboration—NDW and ACCESS will allow businesses to leverage ANL’s expertise and capabilities, but will also create a pathway for ANL’s fundamental research to build avenues towards product development, according to the press release.

Collaboration with NDW and ACCESS will be open to all companies, although “a strong emphasis will be placed on helping small businesses and startups, which are drivers of job creation and receive a large portion of the risk capital in this country,” according to the release.

Andreas Roelofs and Jeff Chamberlain will lead NDW and ACCESS, respectively. Both directors have previous experience creating startups, providing them with unique insights to direct these collaborative centers.

“Where ACCESS and NDW will differ from the conventional approach is through creating an efficient way for a business to build a customized, multi-disciplinary team that can address anything from small technical questions to broad challenges that require massive resources,” Chamberlain says in the release. “That might mean assembling a team with chemists, physicists, computer scientists, materials engineers, imaging experts, or mechanical and electrical engineers—the list goes on and on. It’s that ability to tap the full spectrum of cross-cutting expertise at Argonne that will really make the difference.”

Read more about the expertise and possibilities for collaboration with each center at the NDW and ACCESS websites.

Collaborative efforts that blur the boundaries between the academia, industry, and government lines seem to be a trend to tackle some of the world’s biggest problems. Earlier this year we reported on a new program at DOE to strengthen lab–industry partnerships, for example. And NSF just doled out some serious cash to build its own big data brain trust.

ACerS also sees the potential of bringing together minds from various institutions, as evidenced by the NIST AMTech grant it scored earlier this year to form the Functional Glass Manufacturing Innovation Consortium (FGMIC). FGMIC will bring together academic and government research experience to help solve glass manufacturing challenges important in industry. More about that here.

Author

April Gocha

CTT Categories

- Energy

- Manufacturing

- Material Innovations

- Nanomaterials

Spotlight Categories

- Member Highlights