[Image above] Ferroelectric single-crystal-architecture-in-glass (SCAG) optical fibers could revolutionize optical data transmission technology. Credit: Groman123, Flickr

During this year’s polar vortex that had people barricading themselves indoors, many likely took the opportunity to catch up on Game of Thrones (only two months until the final season premiere!), call friends to complain about the weather, and scroll endlessly through meme pages on Facebook and Instagram. These three activities have more in common than just distractions from the bitter cold—all three activities rely on optical fibers to work.

Fiber-optic communication represents the primary application for photonic integrated circuits (PICs), devices that send information via pulses of light rather than electrons. In addition to revolutionizing communication technologies, PICs also greatly impact biomedical and computing fields.

To control light direction in fiber-optic cables, a basic optical fiber consists of a cladding and core, each with a different refractive index. While this approach works fine for general transmission of data, some PIC applications require more than just controlling direction of light—they require waveguides that can modify fundamental characteristics of optical signals, such as wavelength.

While basic fiber optic cables can send light down a long path, some photonic integrated circuit devices require specific waveguides for fine-tuned control over light direction. Credit: Gringer, Wikimedia

Various techniques can fabricate waveguides within optical fibers, but one area of extensive research looks to create single crystals within a glass fiber. Single-crystal waveguides could modify fundamental optical signal characteristics, but they cannot be created in glass during initial processing.

To create single crystals, most processes use a liquid-solid transformation, in which material is melted and then re-solidified into a single-crystal state. However, there are drawbacks to using liquid-solid transformations—single crystals cannot be created from melts if they have a composition that decomposes, transforms into an undesirable phase, or melts incongruently on heating.

Scientists hypothesized that signal crystals could be formed via solid-solid transformation if a glassy material was heated locally by a laser to just its crystallization temperature—but is this process feasible in real life?

It is, and new research demonstrates just how advantageous solid-solid transformation can be.

In 2016, researchers at Lehigh University successfully performed the solid-solid fabrication process, called single-crystal-architecture-in-glass (SCAG), using antimony-sulfur-iodine glasses. Himanshu Jain, ACerS Fellow and professor of materials science and engineering, and Volkmar Dierolf, ACerS member and professor of physics, oversaw the research. In new research published in December, they and lead author Keith Veenhuizen, assistant professor of physics at Lebanon Valley College, collaborated with Oak Ridge National Laboratory and Corning Inc. to further explore single crystals fabricated using SCAG—with a focus on ferroelectrics.

“A ferroelectric waveguide, which cannot be a glass, allows, in addition to guiding [light] along its length, the manipulation of light by [an] electric field,” Jain writes in an email. However, Jain explains that ferroelectric ceramics are generally used as freestanding pieces, and constraining them mechanically can suppress ferroelectric behavior. “At the outset it was unclear to us if such a crystal when grown and physically constrained inside the glass would be able to retain its ferroelectric behavior and corresponding active properties,” Jain adds.

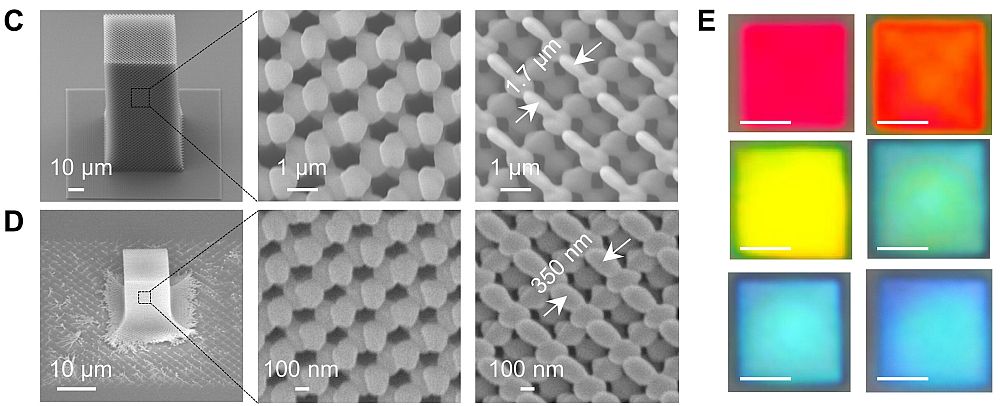

The researchers performed electron backscatter diffraction and piezoresponse force microscope (PFM) measurements on lithium niobosilicate glass to generate theoretical and experimental piezoresponse maps, respectively, for comparison. They found that, except for a specific region near the grain boundary, both maps agreed with each other and showed what the researchers were hoping for—a ferroelectric domain structure.

“The PFM maps indicate the as-grown crystals possess a non-uniform ferroelectric domain structure consisting of oppositely oriented domains on the micro- and nano-scale,” the researchers say in the paper.

(a) A PFM scan showing, from left to right, the vertical response amplitude, vertical response phase, and topography of the as-grown crystal shown. (b) A PFM scan showing, from left to right, the vertical response amplitude, vertical response phase, and topography of the poled crystal. Poling was performed at an elevated temperature of 100°C. The yellow dots act as a guide in comparing the as-grown and poled crystal. Credit: Keith Veenhuizen, MRS Communications

Though this discovery was promising—ferroelectric behavior could occur when the crystal was constrained within glass!—Jain explains most photonic applications “would like to have uniform domain structure so that desired properties can be realized in a predictable manner.” So, the next step for the researchers was to see if they could uniformly orient the ferroelectric domain structure even though it was surrounded by glass.

To modify ferroelectric domain structure, the researchers used the PFM cantilever tip to perform a two-step poling process (a process used for polarizing bulk lithium niobate (LiNbO3) single crystal). The experiment did not work at room temperature (as it does for bulk LiNbO3 single crystal), but it succeeded when the sample temperature was elevated to 100°C (212°F). After 24 hours, the modified regions remained stable and unaltered.

In a Lehigh University press release, Dierolf elaborates on the importance of the discovery. “Being able to embed such functional single crystal architectures within a glass enables high efficiency coupling to existing glass fiber networks,” he says. “Such low loss links―that maximize performance―are of particular importance for future quantum information transfer systems that are projected to take over the current schemes for optical communication.”

In an email, Jain explains that the team has an extensive, ongoing program “to perfect the quality of single crystal architecture fabricated in glass, and also provide new controls on the characteristics of such crystals, such as their orientation.” Additionally, Jain says the partnership with Corning ensures the work will progress toward a realistic application in a reasonable time.

“We discuss the results every 2–3 weeks, and our partners at Corning provide feedback regularly and also facilitate testing of the structures fabricated at Lehigh at their facility,” Jain adds.

Curious about other research taking place on glass electromagnetic properties? Make sure to attend session 12 of Symposium II: Glass Physics at the International Congress on Glass (ICG 2019), held June 9–14 in Boston!

The paper, published in MRS Communications, is “Ferroelectric domain engineering of lithium niobite single crystal confined in glass” (DOI: 10.1557/mrc.2018.234).

Updates 02/15/2019: Article updated to include name of lead author, and to more accurately explain why single crystals are desirable as waveguides in glass.

Author

Lisa McDonald

CTT Categories

- Glass

- Optics