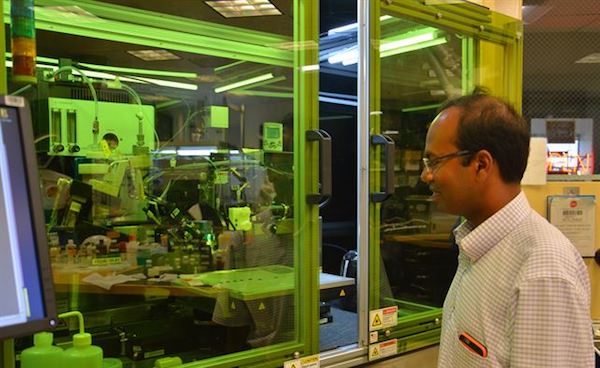

[Image above] Santanu Bag, a project scientist at the Materials and Manufacturing Directorate at the Air Force Research Laboratory, explores cost-efficient manufacturing of solar cells using additive technology. Credit: Air Force Research Laboratory, Wright-Patterson Air Force Base

Some of the biggest challenges of photovoltaic research include improving efficiency and making solar cells more cost-effective.

Back in the day (the 1800s) early solar technologies were not even 1% efficient. Solar cell efficiency got a boost in the 1960s when researchers achieved 14% efficiency in photovoltaic cells. Since then, efficiency has gradually increased with advances in research, as the timeline in this article indicates.

But factors such as complicated fabrication methods and labor-intensive equipment have contributed to high manufacturing costs and smaller margins for manufacturers, impeding widespread adoption of solar power.

Researchers at Wright-Patterson Air Force Base (WPAFB) in Dayton, Ohio, are working to increase efficiency and eventually lower manufacturing costs of solar cells. Santanu Bag, a project scientist leading a research team at WPAFB, is taking a page (pun intended) from newspaper printing to create solar cells out of thin-film perovskites.

Solar cells are typically made with pure crystalline silicon and formed into flat wafers. But perovskites are being studied by solar researchers because of the material’s superconductive properties, low cost, ease of fabrication, and light-absorbing capabilities.

Because it is not typically found in nature in its pure form, silicon, an inorganic material, requires an enormous amount of energy to extract it from silicon dioxide (sand). And it is very inflexible, which limits its solar applications.

Bag and his team wanted to use a flexible material that could be printed on a flat surface, similar to how newspapers are printed on rolls of paper. “We needed a material that was easy to print and at the same time able to capture sunlight,” Bag says in a WPAFB news release. “We determined an inorganic-organic hybrid material would be easy to print and could still harvest solar energy.”

Which is why he and his team chose thin-film perovskites. According to Bag, thin-film perovskite materials have been around for at least two decades and have previously been used in LED technology. “Researchers knew it had solar ability, but this was not the focus at the time,” Bag adds in the release.

To break down perovskite into a consistency the researchers could use in a printer, they had to atomize the material to create tiny droplets, which they then sprayed through the nozzle of an aerosol-jet printer onto a flat surface. The resulting aerosol-jet printed solar cells had an efficiency of 15.4%.

The researchers also test-printed the material onto a 3-D surface. Although the resulting efficiency was only 5.4%, they are hopeful that they can improve upon it. Bag says they “know it can be done.”

The flexible nature of perovskite material for solar cells offers a wider variety of applications, including clothing, robotics, and self-powered sensors.

“Once you know how to print it, it has huge potential for other applications,” he says. They have already filed an application for a patent, and plan to conduct further research.

For manufacturers, their work could lead to reduced costs, higher margins, and wider adoption of solar cell technologies.

The paper, published in Advanced Energy Materials, is “Aerosol-jet-assisted thin-film growth of CH3NH3PbI3 perovskites—A means to achieve high quality, defect-free films for efficient solar cells” (DOI: 10.1002/aenm.201701151).

Author

Faye Oney

CTT Categories

- Basic Science

- Energy

- Environment

- Manufacturing