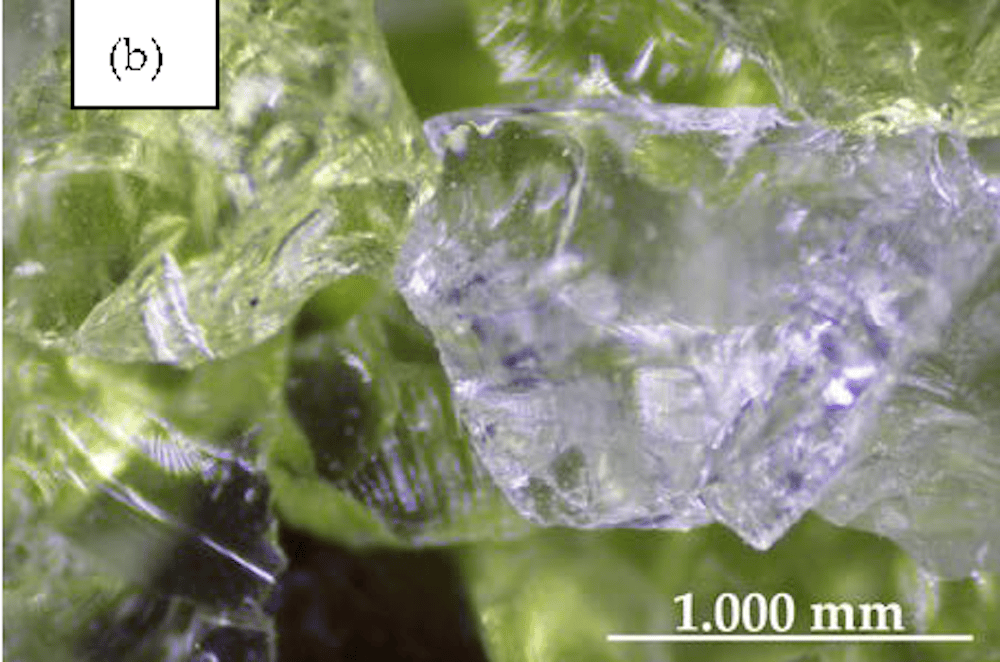

[Image above] Light microscope image of glass aggregate used to create a fiber-reinforced cement–glass composite (45X magnification). Credit: Małek et al., Materials (CC BY 4.0)

As the second most consumed material in the world next to water, concrete unquestionably plays an outsized role in today’s society. It is no wonder, then, that scientists take the environmental impacts of this material seriously and actively research ways to reduce its impact.

Substituting alternative materials for Portland cement in concrete is one way that scientists look to reduce the environmental impact. Up to 8% of the world’s annual carbon dioxide emissions are due to cement production, so using less cement in concrete will help lower the industry’s emissions.

Many of the alternative materials being investigated as cement substitutes, such as fly ash, silica fume, and blast furnace slag, are byproducts from other processes. By using these materials to replace some of the cement, researchers also address the problem of material waste through reuse.

Glass cullet is one waste material being investigated for use in concrete as aggregate. However, “It was found that the use of glass cullet as replacement for coarse aggregate is not satisfactory owing to the reduction of the bonding between the aggregate and the cement matrix, and a reduction of strength,” researchers write in a recent open-access paper.

The researchers come from the Military University of Technology in Warsaw and the Building Research Institute in Poland. They note that adding plastic fibers to a cement–glass composite is one way of potentially improving the mechanical properties, but such an approach remains rarely reported. Therefore, they decided to investigate the approach themselves using polypropylene fibers from post-consumer waste (i.e., food packaging).

They created a glass-based concrete by mixing 100% granulated glass aggregate with Portland cement, tap water, and polycarboxylate superplasticizer. Then, they added polypropylene fiber in mass percentages of about 0.0625%, 0.1250%, 0.1875%, 0.2500%, and 0.3125% to create five different modifications of the cement–glass composite. After 28 days of curing, the hardened concrete was investigated for compressive strength, splitting strength, and flexural strength, in addition to density and modulus of elasticity.

The researchers found that compressive strength increased slightly with the increase in fiber content, achieving values 1.5-times higher than for plain concrete of similar composition (with granite aggregate instead of glass). “This is probably the result of the use of glass powder to ensure the continuity of the internal structure of the material, which in turn results in an increase in mechanical strength by reducing the air pores in the cement hydration process,” they write.

Flexural strength and splitting strength also increased with higher fiber content, but the values were lower compared to plain concrete (half as much and two-times lower, respectively).

“According to Tan and Du, the reduction in flexural strength is caused by a decrease in adhesive strength at the glass particle surface and cement matrix and, additionally, micro-cracks in the case of clear glass aggregate,” the researchers write. However, they do not explicitly state the reason for the difference in splitting strength.

They also found that the cement–glass composite density increased linearly with the increase in fiber content, though the density remained less than for plain concrete. The modulus of elasticity was comparable to plain concrete.

In the conclusion, the researchers say that the results suggest “elements with no significant deflections, such as columns or sheet piling, can be made of a cement–glass composite (preferably with the highest obtained mechanical properties, e.g., recipe M5 with addition of 0.3125% PP fibres).” They plan to conduct further tests on other types of cement, glass waste and its mixes, and different contents of glass powder, with particular emphasis on long-term fatigue tests.

The open-access paper, published in Materials, is “Physical and mechanical properties of polypropylene fibre-reinforced cement–glass composite” (DOI: 10.3390/ma14030637).

Author

Lisa McDonald

CTT Categories

- Cement

- Construction

- Environment

- Glass