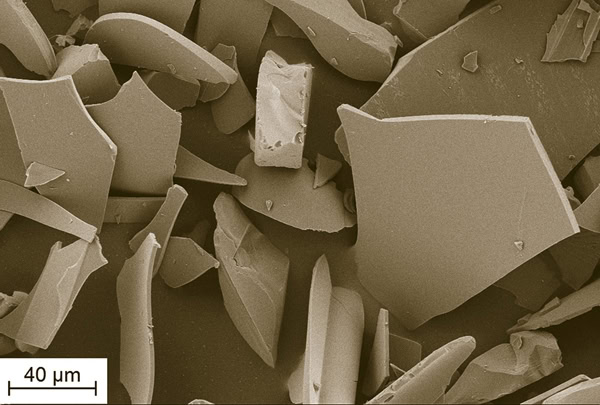

[Image above] Flakes of porous glass added to a plaster mixture could someday help regulate the humidity and heating and cooling costs within your home. Credit: Fraunhofer ISC

Whether summer or winter, it takes a lot of work to keep the indoors from feeling like the outdoors.

Too much heat—or too little cold—often means too much humidity. And while humidity can wreak havoc on your hair (Smithsonian explains why here), it’s even worse for your home and health.

Mildewed and moldy walls can cause rot and structural damage, or destroy that perfect greige paint job that took you two days.

They also can cause allergic or hay-fever-like reactions—sneezing, runny nose, red eyes, or rash—in “sensitive individuals” or attacks in asthmatics.

(FYI: To prevent those problems, Energy Star recommends that your home’s humidity levels hover somewhere between 30 and 50 percent.)

Air conditioners, dehumidifiers, and exhaust fans can all help to control humidity—but what if regulating the right indoor environment were simply a matter of using more mold-resistant materials?

Research out of the Fraunhofer Institute for Silicate Research ISC (Würzburg, Germany) shows that the addition of manufactured porous glass to paint or plaster can help your home better regulate the indoor climate—particularly, humidity.

Working with Bayreuth University and Keimfarben GmbH, the Fraunhofer team, led by Ferdinand Somorowsky, focused their research on supplements of Vycor-based glass particles, which, in their flake form, can “quickly absorb, store, and then slowly release moisture.”

“As invisible vapor, there is always water in the air. A pleasant indoor climate only remains pleasant when excess moisture released into the room’s air by showering, cooking, and sweating can also dissipate again somehow,” explains Somorowsky in a Fraunhofer news release. “Walls and ceilings offer large surfaces that could be used for moisture management—and by adding glass particles to plaster, stucco, and paint, we can even out daily and seasonal humidity differences. The result is a simply more comfortable living space. Up to now, between 95 and 98 percent of all plasters available have been without additives.”

The pores in the Vycor glass allow for “selective modification”—which allowed scientists to create materials that morph with the size (“just a few nanometers to several micrometers”) of the pores as needed.

“Since porosity and pore size can be exactly specified, we can also regulate humidity effectively. A minimal change in pore size adapts the material for different temperatures and various applications, such as living areas, rooms with consistently higher humidity, or basement rooms,” says Somorowsky.

In testing, researchers demonstrated that the glass flake–plaster mixture could absorb—and subsequently release—more moisture than materials like zeolite or fiberboard.

According to the release, the material “proved itself superior” in further tests against “benchmark” plasters.

“In a room with a volume of 30 cubic meters, the walls and ceiling offer approximately 40 square meters of surface area that could be used for a moisture regulating plaster. In order to reduce the humidity from 72% to 47%, some 180 mL of water needs to be absorbed. And our glass flake plaster can actually adsorb more than a half liter of water,” says Somorowsky.

More impressive, however, than the glass-based material’s ability to absorb moisture is the positive impact the moisture-regulating material could provide to the energy balance in your home.

When humidity is high, water is adsorbed and the release of energy makes the room both drier and warmer. When humidity is low, however, desorption cools and humidifies the space. This could help homeowners save on heating and cooling costs, with particular benefit during extended periods of heating during winter. (That’s certain to be welcome news to anyone who lived through last winter’s polar vortex.)

The group, which is currently studying the effectiveness of the additive when applied under additional layers of paint or wallpaper, anticipates that it will be at least two more years until the plaster makes it to market.

Author

Jessica McMathis

CTT Categories

- Construction

- Energy

- Glass

- Material Innovations