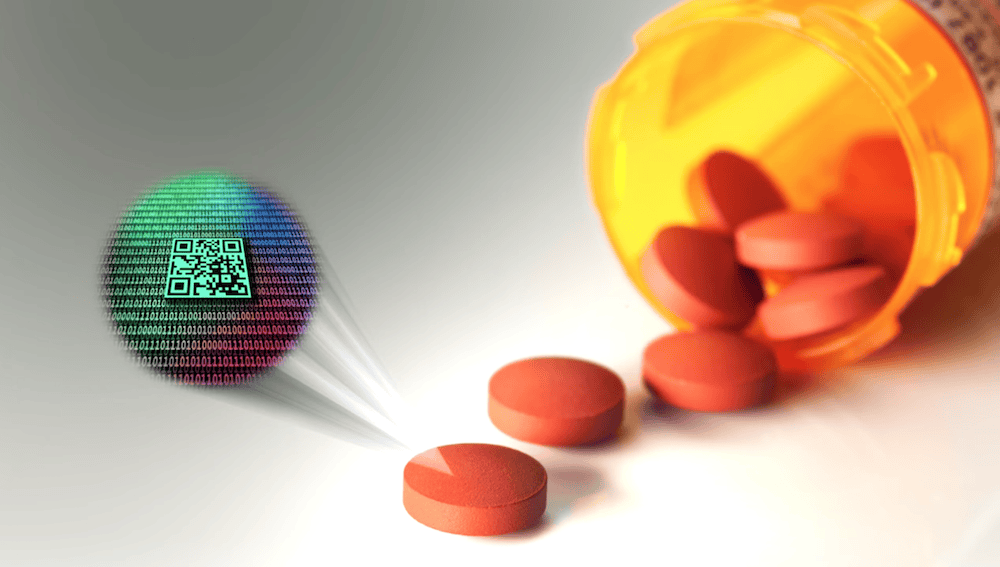

[Image above] Credit: Trutag Technologies; YouTube

Today, you can buy almost anything online.

But how do know that what you order off Amazon.com and have shipped to your door the next day is actually what it says it is—whether it’s olive oil or headphones?

In today’s world of global commerce, product identity is a significant issue with considerable economic repercussions. Fake goods account for 3.3% of world trade, an estimated $509 billion value.

Loss of control in these supply chains can make it incredibly difficult to verify the provenance of products—whether those products are actually counterfeit goods or mislabeled products (different product, same name) or items that have been produced without authorization (same product, different name).

In either case, fake goods are one thing when we’re talking about counterfeit designer handbags or sneakers, but it is an entirely different and potentially much more dangerous issue when it comes to things like aeronautical components or pharmaceuticals.

That is why smart new strategies to combat fake goods are an incredibly important issue in today’s complicated global supply chains and an area that is ripe for innovation in materials science-based solutions.

For example, the August 2016 ACerS Bulletin included a feature article detailing efforts to develop porous-wall, hollow glass microspheres as an anti-counterfeiting solution. These glass microspheres can be loaded with various functional security materials, including gases, liquids, and solids, which are inserted into the microspheres through pores on their surface. These versatile security materials can then be loaded into an ink and printed onto the surface of a product, providing a means to identify and verify it.

Now, another security solution that also uses porous silica nanoparticles, but in a completely different manner, seems to be gaining momentum.

A company called TruTag Technologies (Emeryville, Calif.) has secured a total $25 million in funding to date for its anti-counterfeiting technology of porous silica nanoparticles that use unique spectral signatures to authenticate goods.

These nanoparticle tags can be applied to a whole host of diverse products, and because silica is “generally recognized as safe” by the U.S. Food and Drug Administration, they are edible as well—opening the possibility for this anti-counterfeiting solution to apply to everything from pharmaceuticals and foodstuffs to documents and microelectronics.

So how does it work?

I spoke with Barry McDonogh, TruTag Technologies’ senior vice president of business development, who explained that the company uses a process to alter silica nanoparticles’ surface, making it porous. This processing step can precisely control the shape, size, and depth of the pores, affording the ability to uniquely pattern the surface of silica nanoparticles (which range in sizes of ~8–20 µm by ~25–70 µm).

When light is shined on those uniquely patterned porous nanoparticles, they reflect back an equally unique spectral signature that functions as a barcode. That signature can be tied to a product’s identity as well as specific manufacturing information, such as the lot number and location where a product was manufactured, to verify its provenance.

These invisible and stable silica microtags can be mixed into various types of carriers and can be applied to a product in diverse ways, often piggybacking on an existing processing step to simplify manufacturing.

For instance, tags can be printed in ink or varnish or even spray-coated onto the surface of a product. “Tags can get mixed into a master batch and literally be extruded into films,” McDonogh says. “So there is real diversity in the ways they can be applied. We always look for the easiest way so that the customer doesn’t have to change their business process.”

One industry that TruTag Technologies is focused on is pharmaceutics. So, for example, its porously patterned silica nanoparticles can be directly mixed into the film coating that is already sprayed onto a drug tablet, meaning no extra steps, printing, or application required. See more in the video below.

Credit: Trutag Technologies; YouTube

The tags’ signature is read via hyperspectral imaging—which collects a wide spectrum of wavelengths that extend beyond normal color imaging—so the technology provides the ability to encode an incredible diversity of individual codes to identify unique products.

The company also developed its own handheld portable hyperspectral imaging device (a significant advancement on its own) to scan its nanoparticle tags in a matter of seconds, offering the ability to authenticate products nearly anywhere in real-time.

TruTag Technologies even developed a simplified version of its technology that uses a smartphone app and camera to authenticate products. While more limited in potential signatures (the smartphone tech is spectral, not hyperspectral), it nonetheless opens the possibility of bringing product verification directly into the hands of consumers.

And in a world where products are often not what they claim to be—listen to this podcast and you’ll never look at calamari the same way—I definitely welcome that possibility.

Author

April Gocha

CTT Categories

- Material Innovations

- Nanomaterials

Spotlight Categories

- Member Highlights