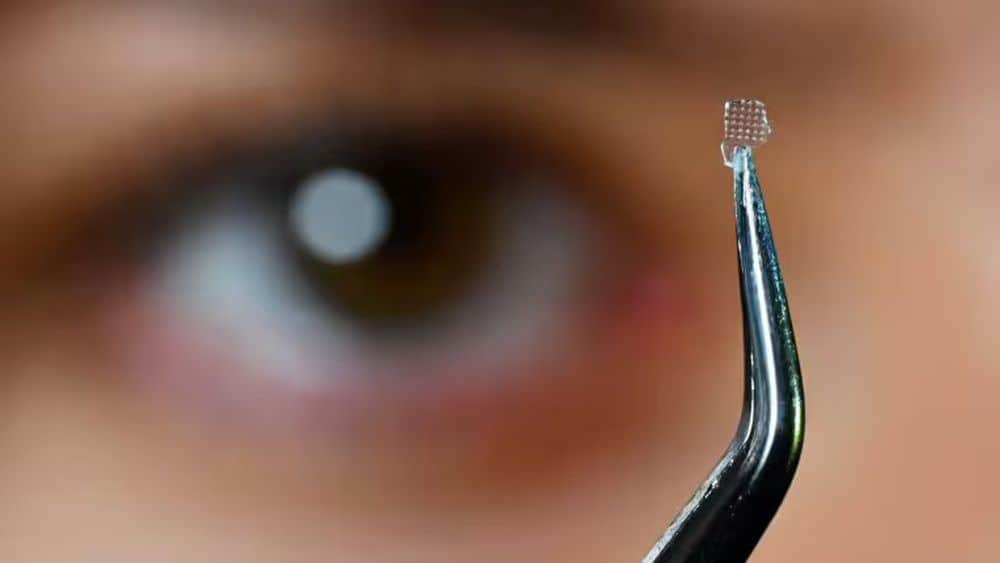

[Image above] Ph.D. student Oksana Smirnova holds up an optical microlenses made of a metal–organic framework glass. Credit: Jens Meyer, Friedrich Schiller University Jena

Glass is a uniquely rich material system, capable of being formed from virtually any element as long as the right composition and processing parameters are used. And yet, soda lime silicate accounts for approximately 90% of all commercial glass production due to its convenience of being relatively inexpensive, chemically stable, reasonably hard, and extremely workable.

In recent years, though, some niche and emerging glass systems began filtering into public awareness. For example, chalcogenide glasses, which were the focus of the May 2024 Bulletin cover story, offer desirable infrared light transmission. Advances in the past six decades mean chalcogenide glasses are now found commercially in thermal imaging systems and rewritable memory devices, among other applications, with great potential for further market expansion.

Likewise, the patent-pending LionGlass family of zinc aluminosilicophosphates glasses, developed by ACerS Fellow John Mauro and his colleagues at The Pennsylvania State University, is advancing very quickly to commercialization due to its potential to replace soda-lime glass.

Metal–organic frameworks (MOFs) are another material system that is gaining attention within the glass community. Comprised of inorganic nodes joined by organic linkers, MOFs are typically formed in a crystalline state, but recent studies show that several MOFs can be formed as glasses as well.

This past Tuesday on CTT, we demonstrated the potential of MOF glasses in application through the example of a dendrite-mitigating layer in lithium-metal batteries. However, though these glasses are about to enter their second decade of discovery, “the shaping of [these] hybrid glasses in their liquid state—in analogy to conventional glass processing—has been elusive thus far,” researchers write in a recent open-access paper.

The researchers come from Friedrich Schiller University Jena and Leibniz Institute of Photonic Technology in Germany. They are led by University of Jena professor Lothar Wondraczek, whose work on MOFs was previously showcased in the ACerS Bulletin.

Last year, in December 2023, the researchers reported that they had developed a procedure for liquid handling of high-quality zeolitic imidazolate MOF glasses, specifically composition ZIF-62. Their process involves placing gently ground ZIF-62 crystals between two silica cover glasses and then heating the sample in a tube furnace. Upon melting, the transparent ZIF-62 glass could be transferred to a mold and pressed into almost any desired shape.

Schematic of the workflow from ZIF-62 crystals to imprinted micro-optical components made of ZIF-62 glass. Credit: Smirnova et al., Nature Communications (CC BY 4.0)

The hot imprinted ZIF-62 glasses featured accessible pore channels, which allowed the glass to be used as a gas sensor. When gas molecules entered the 3D lattice structure, the glass demonstrated an observable shift in optical properties under direct infrared imaging.

In the new study, the researchers imprinted the ZIF-62 glasses with concave and convex micro-optical components to further explore the potential of these glasses in real-world optical applications. Their experiments resulted in centimeter-scale samples that could reversibly adsorb volatile gas molecules, thus allowing “optical breathing,” i.e., reversibility of the optical path length.

“This result paves a way for realizing responsive optical elements based on microporous MOF-derived glasses,” the researchers write.

The open-access paper, published in Nature Communications, is “Micro-optical elements from optical-quality ZIF-62 hybrid glasses by hot imprinting” (DOI: 10.1038/s41467-024-49428-1).

Author

Lisa McDonald

CTT Categories

- Glass

- Material Innovations