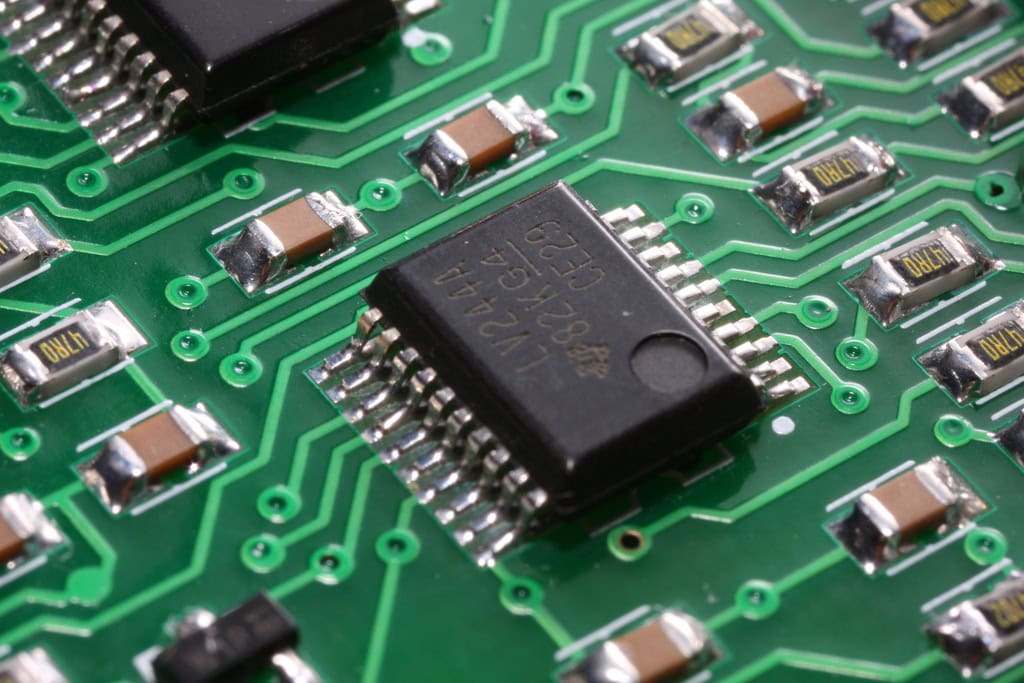

[Image above] Andrew Magill; Flickr CC BY 2.0

The buzz continues when it comes to the potential use of graphene in commercially available electronics. In the age of ultra-fast, handheld super computers, there’s never been more demand for increasing the speed and efficiency of the devices we rely on to do so much for us.

Last month I reported that the time-to-market gap for commercially viable graphene in electronic applications could be narrowing. And that gap might just have shrunk even more, according to recent research from the Advanced Materials for Energy and Electronics Group at the University of Wisconsin-Madison.

Michael Scott Arnold, associate professor in the materials science and engineering department at UW-Madison, and his engineering team demonstrate a promising new approach to manufacture a crucial form of graphene in a paper published Aug. 10 in Nature Communications.

Graphene’s single-layer thickness, toughness, and supreme mechanical and thermal properties make it an ideal choice for developing electronic, optoelectronic, and electromechanical devices and sensors. But scaling up commercially viable graphene for electronic applications has been complicated and expensive.

So Arnold and his team have developed a promising new technique for manufacturing graphene—ultra-thin ribbons of graphene, to be exact—that can be made into high-performing transistors in digital processing applications.

The technique involves growing “graphene nanoribbons with desirable semiconducting properties directly on a conventional germanium semiconductor wafer,” according to a UW-Madison College of Engineering news release about the research.

But in order to harness graphene’s electronic properties in semiconductor applications where currents need to be switched on and off, “graphene nanoribbons need to be less than 10 nanometers wide, which is phenomenally narrow, and have smooth, well-defined ‘armchair’ edges in which the carbon-carbon bonds are parallel to the length of the ribbon,” according to the news release.

“What we’ve discovered is that when graphene grows on germanium, it naturally forms nanoribbons with these very smooth, armchair edges,” Arnold says. “The widths can be very, very narrow and the lengths of the ribbons can be very long, so all the desirable features we want in graphene nanoribbons are happening automatically with this technique” Arnold says in the release.

Progressively zoomed-in images of graphene nanoribbons grown on germanium. The ribbons automatically align perpendicularly and naturally grow with their edges oriented along the carbon-carbon bond direction, known as the armchair edge configuration. Credit: Arnold Research Group and Guisinger Research Group

This breakthrough “could allow manufacturers to easily use graphene nanoribbons in hybrid integrated circuits, which promise to significantly boost the performance of next-generation electronic devices,” according to the news release.

Critically, Arnold says this technique is easily scalable for mass production and can be integrated into existing systems of semiconductor processing.

“Graphene nanoribbons that can be grown directly on the surface of a semiconductor like germanium are more compatible with planar processing that’s used in the semiconductor industry, and so there would be less of a barrier to integrating these really excellent materials into electronics in the future,” Arnold says in the release.

The paper, published in Nature Communications, is “Direct oriented growth of armchair graphene nanoribbons on germanium” (DOI: 10.1038/ncomms9006).

Author

Stephanie Liverani

CTT Categories

- Electronics

- Manufacturing