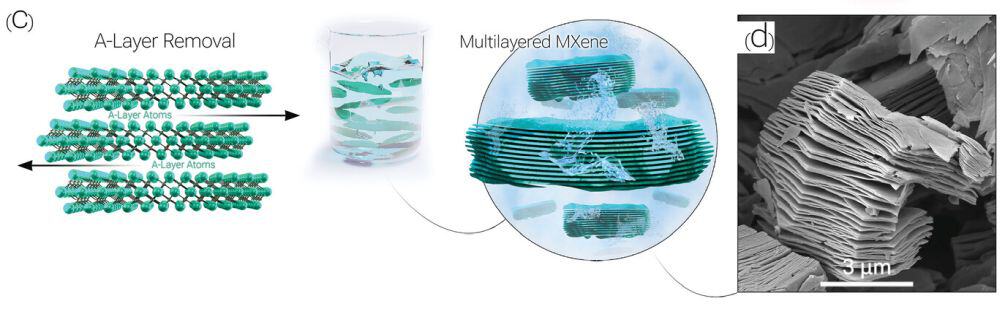

[Image above] Schematic representation of the production of Ti3C2Tx MXenes on a small scale for potential industrial use. The steps shown above include the removal of A-layer atoms (aluminum) through selective etching in the topochemical production of MXene, leaving behind stacked MXene flakes. Credit: Firouzjaei et al., Advanced Materials (CC BY-NC 4.0)

The development of materials for new and improved clean energy technologies is an important step toward creating a more sustainable world. But “how often do we acknowledge, evaluate, and rationalize the environmental impacts linked to producing a material?”

This question, which was posed in the September 2023 Bulletin letter to the editor, calls attention to the dearth of environmental assessments in many sectors. Even when assessments are conducted, they often are performed at a late developmental stage where, due to economic reasons, a process modification is unfeasible, regardless of the results.

Transitioning to a sustainable circular economy will require environmental impacts to be considered during the early stages of materials and product development. Fortunately, ACerS members are helping promote this adoption by conducting environmental assessments themselves. For example, the open-access life cycle assessment of MXene synthesis that published in April 2023.

MXenes are a family of 2D transition metal carbides, nitrides, and carbonitrides that demonstrate a wide range of chemical and structural diversity. This diversity leads to a range of impressive material behaviors, including high electrical conductivity, high mechanical stiffness, solution processibility, and high-temperature stability.

Originally discovered in 2011 by two groups of researchers at Drexel University, MXenes have seen an outpour of attention from the materials science community, which has led to the material’s usage in many sectors—with future applications continuously emerging.

Despite the meteoric rise of MXenes from discovery to commercial products in only a decade, the environmental impacts of MXene synthesis have not been assessed systematically.

“The lack of this knowledge might result in missed opportunities to incorporate greenness into the scale-up and industrialization of MXene production,” researchers write in the open-access paper.

The researchers are led by ACerS member Babak Anasori, assistant professor of mechanical and energy engineering at Indiana University–Purdue University Indianapolis, and Mark Elliott, professor of civil, construction, and environmental engineering at the University of Alabama.

In their paper, they conducted a “cradle-to-gate” life cycle assessment (LCA) of Ti3C2Tx MXene production, starting with raw material extraction and covering through manufacturing.

They specifically evaluated Ti3C2Tx MXenes produced as a coating layer for communications satellites’ electromagnetic interference (EMI) shielding because “it is a well-known platform that requires EMI shielding and for which the detailed data required for LCA were available,” they explain.

As MXenes are not yet employed for industrial-scale EMI shielding applications, they evaluated two laboratory-scale sizes of MXene synthesis in this study: a small lab scale (19.2 g per batch) and a large lab scale (800 g per batch). They curated inventory data from their own lab notes as well as various published studies on laboratory-scale syntheses of MXenes.

The results of their LCA, which they state “is the first report on the LCA of any MXene composition,” suggests that electricity consumption plays the most important role in the environmental impacts of Ti3C2Tx MXene synthesis in the laboratory.

“For [the large kilogram batch] Ti3C2Tx MXene, electricity consumption accounts for over 70% of adverse environmental effects, and for [the small gram batch] Ti3C2Tx MXene, it accounts for 90%,” they write. “As a result, the nature of the energy resources determines most of the environmental impact.”

Based on this result, they suggested that methods to reduce energy consumption during MXene synthesis would be the best way to reduce the process’s environmental impact. For example, reducing the energy consumption of electrical equipment and shortening the synthesis time.

However, “A screening-level LCA may not accurately predict the environmental burdens by a direct scale-up because scaling up can introduce additional uncertainties,” the researchers add. “Therefore, higher reaction yields, the recycling of reagents, and more efficient equipment are expected to reduce the associated environmental impact and energy required for the unit mass of Ti3C2Tx MXenes produced at the industrial scale compared to those at a laboratory scale.”

In May 2023, Anasori led another open-access study that contributes to reducing the environmental impact of MXene synthesis. In that paper, he and colleagues from Indiana University–Purdue University Indianapolis and the University of Pennsylvania presented a detailed, systematic guide for synthesizing high-quality MXenes that can be consistently reproduced.

In addition to establishing a better understanding of various experimental conditions, their optimal stepwise synthesis process “holds the potential to be scaled to manufacturing levels,” they write.

The April 2023 open-access paper, published in Advanced Materials, is “Life cycle assessment of Ti3C2Tx MXene synthesis” (DOI: 10.1002/adma.202300422).

The May 2023 open-access paper, published in Small Methods, is “Step-by-step guide for synthesis and delamination of Ti3C2Tx MXene” (DOI: 10.1002/smtd.202300030).

Author

Lisa McDonald

CTT Categories

- Environment

- Nanomaterials