[Image above] Credit: Andrew Magill; Flickr CC BY 2.0

Sure, diamonds are pretty—pretty darn tough.

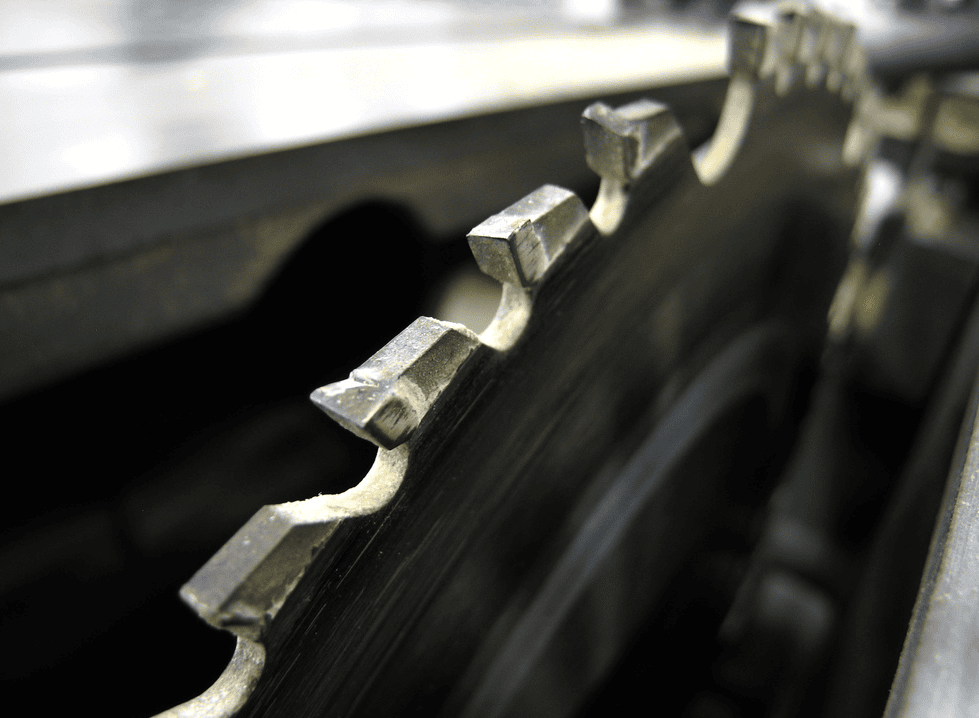

Diamond-outfitted machining tools may not have the ‘bling’ of crystal-studded arm candy, but it’s those diamonds that help sharpen blades used to cut, grind, and slice through hard materials like steel and ceramics.

But diamonds aren’t necessarily easy to make in the lab—they require incredibly high temperatures and massive pressure to produce.

Late last year, researchers from North Carolina State University discovered a new phase of solid carbon that is actually harder than diamond and can be formed at room temperature and at ambient atmospheric pressure.

Called Q-carbon, this new phase is distinct from the known phases of graphite and diamond.

“We’ve now created a third solid phase of carbon,” ACerS member Jay Narayan, who is also John C. Fan Distinguished Chair Professor of Materials Science and Engineering at NC State and lead author of the papers describing the work, said in a NC State news release at the time. “The only place it may be found in the natural world would be possibly in the core of some planets.”

Narayan and his team found that Q-carbon has some unusual characteristics—one being the fact that it’s ferromagnetic, a characteristic that doesn’t apply to other solid forms of carbon.

And earlier this year, Narayan and his colleagues made news again.

In addition to discovering Q-BN, they also developed a new technique for creating cubic boron nitride (c-BN) at ambient temperature and pressure, a technique that could lead to advancements across many applications, including power grid technologies.

“This is a sequel to our Q-carbon discovery and converting Q-carbon into diamond,” Narayan said in a news release back in February. “We have bypassed what were thought to be the limits of boron nitride’s thermodynamics with the help of kinetics and time control.”

Now this week, the team revealed part three of their research.

They developed a new technique to deposit diamond on the surface of cubic boron nitride (c-BN), integrating the two materials into a single crystalline structure that can be used in high-power devices.

“This could be used to create high-power devices, such as the solid state transformers needed to create the next generation ‘smart’ power grid,” says Narayan in a NC State news release this week. “It could also be used to create cutting tools, high-speed machining, and deep sea drilling equipment.”

Diamond is hard, but tends to oxidize, explains Narayan. The oxidation transforms diamond into graphite, which is softer, he says.

“A coating of c-BN would prevent oxidation. Diamond also interacts with iron, making it difficult to use with steel tools. Again, c-BN would address the problem,” he adds.

To create the single-crystal diamond/c-BN structures, first the team creates a substrate of c-BN using the new technique they published earlier this year. Then, through a process called pulse-laser deposition—which is done at 500ºC and an optimized atmospheric pressure that allows the scientists to to control the the diamond layer’s thickness—they deposit diamond on the surface of the c-BN.

Raman spectra from diamond/c-BN single crystal films. Credit: Jay Narayan; NC State

“This is all done in a single chamber, making the process more energy- and time-efficient,” Narayan says. “You use only solid state carbon and BN, and it’s more environmentally benign than conventional techniques.”

The team was able to deposit diamond on the c-BN substrate using the conventional chemical vapor technique—but that method uses methane gas, hydrogen gas, and a tungsten filament at 900°C, which raises safety and environmental concerns.

“The chemical vapor deposition approach works, but our pulsed laser deposition approach works much better, doesn’t involve toxic gases, and can be done at much lower temperatures,” Narayan says.

Narayan’s company, Q-Carbon LLC, has licensed the new technique and is working to commercialize it for multiple applications.

Narayan and his team’s latest research, published in the Journal of Applied Physics, is “Direct conversion of h-BN into c-BN and formation of epitaxial c-BN/diamond heterostructures” (DOI: 10.1063/1.4948688).

Author

Stephanie Liverani

CTT Categories

- Manufacturing

- Material Innovations