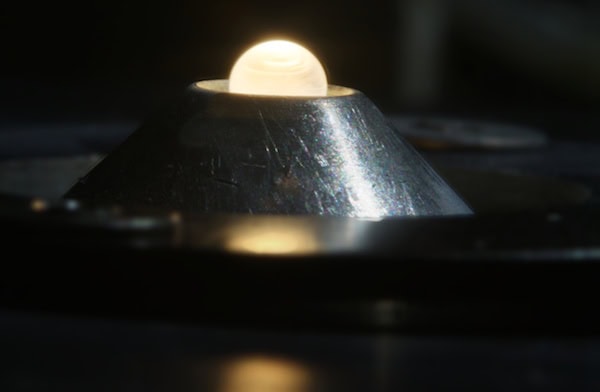

[Image above] Researchers studying the behavior of high-temperature ceramics levitate a drop of metal oxide in a flow of gas, heating it from above with a laser beam. Credit: Oak Ridge National Laboratory

Researchers from Stony Brook University, in collaboration with Oak Ridge and Argonne national laboratories, have unveiled new insights into the structures of liquid metal oxides.

To do so, the researchers levitated samples of yttrium and holmium oxides, heated them up with a carbon dioxide laser, and blasted them with X-rays and neutrons—talk about a rough day to be a ceramic.

The results, published in Physical Review Letters, show that there is “a general trend towards lower metal and oxygen coordination in a wide range of oxide melts, suggesting that this behavior is a widely occurring phenomenon,” according to an ORNL press release.

Although understanding the structure of liquid metal oxides is important for their use in high temperature-resistant applications, the results also have other wide-ranging implications, including in the evolution of planetary bodies, nuclear meltdown scenarios, and glass formation.

To prevent the sample from contamination, reaction, or influence from any surface during the testing, the researchers levitated a bead of the liquid metal oxide in mid-air. Materials Development Inc., a materials development and consultation company (Arlington Heights, Illinois), collaborated with the team to develop and optimize a special nozzle system that delivers gas flow to levitate a small ceramic bead (~⅛ inch) above the nozzle. (Materials Development also worked with Argonne to create a system for acoustic levitation, which you can see in action here.)

While levitating, a 400-W laser scorched the bead to a searing 3,000 K (~5,000°F). (That’s hot. Really hot. Almost half the surface temperature of the sun [10,300°F] hot.)

The team then used X-rays and neutron diffraction experiments on the glowing hot bead to determine a set of pair distribution functions, the first for a high temperature oxide melt. “Neutrons show us the oxygens in the material clearly, while X-rays reveal the cations [positively charged atoms],” says Argonne physicist Chris Benmore in the press release. “If you want to extract the detailed structure, you need both techniques.”

“In principle, with this knowledge we could make new families of materials by capturing unusual structural motifs present in the melt that don’t occur in the crystal,” says Benmore. “We want to find out how to stabilize that structure—maybe by adding components or through vitrifying the melt—and end up with same material, but with different properties.”

The paper is “Low cation coordination in oxide melts” (DOI: 10.1103/PhysRevLett.112.157801).

Updated June 16, 2014

Author

April Gocha

CTT Categories

- Basic Science

- Material Innovations