[Image above] Credit: Pocketnow; YouTube

Credit: Pocketnow; YouTube

There have been many gains in the production and application of sapphire over the last decade, but one new application being pursued—cover and touch screens for smartphones and similar devices—has certainly surprised me and is generating some controversy over its commercial feasibility.

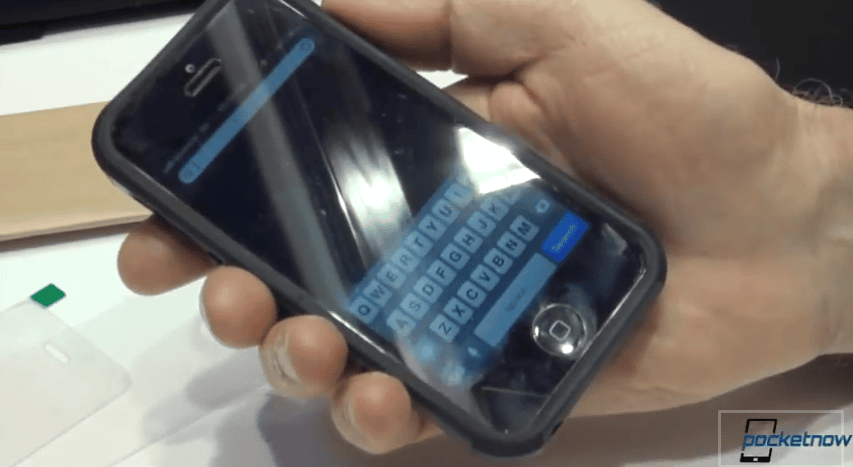

Most of the discussion about sapphire can be traced to GT Advanced Technologies (GT), a Nashua, N.H., company. Back in March, GT had a booth at the Mobile World Congress 2013 show in Barcelona, Spain, where it had a demonstration of an iPhone 5 where the Gorilla Glass 2 (GG2) front cover had been replaced with sapphire (see video above).

I mention the GG2 only because the state-of-the-art glass is Gorilla Glass 3, which has three times the damage resistance of GG2, a huge improvement in an already great product. GG3 is just now debuting on the new Samsung Galaxy S4, and I suspect GG3 will show up in the next generation of iPhones, but Apple notoriously will never admit it.

Now, there is no getting around that sapphire is a wonderfully tough material, as demonstrated by its use in military transparent armor, critical optics (including many of the tiny camera lenses in smartphones) and high-end watch faces. And, I am sure that a sapphire smartphone would highly resist scratching, but … my personal opinion is that the scratching concerns, whether from car keys or sand or whatever, are highly overrated.

My first iPhone 3 fell out of my shirt while I was cycling down California’s Mt. Tam at about 40 mph. As I looked back, I saw the phone skidding and tumbling about 50 feet through the gravel on the shoulder of the road. When I retrieved it, it was face down. I expected the worse, but there was nary a scratch. Nowadays, I stuff my phone in the same pocket with my keys all the time, and I have tossed it into a lot of beach bags with sand.

There still isn’t a scratch on my phone, and I have yet to see one that does, although I am sure it happens sometimes. But I have seen no evidence that scratches are a major shortcoming of Gorilla Glass. (Smearing and difficulty seeing in direct sunlight seem to be bigger problems). I should point out that I am differentiating between scratches and cracks. I have seen several smartphones with the latter, and while scratches can lead to cracks—more on this below—cracks frequently come from impact damage when a phone is dropped on an exposed edge.

Regardless of my anecdotal experiences, sapphire has some definite knocks against it. The material may be very hard, but unlike glass, I know of no way to introduce compressive stress to sapphire. No alkali ions can be introduced to sapphire to “pack” the surface they way that a chemical treatment, for example, does to glass. These ions give glass its retained strength after damage and are what keeps damage, even smaller than visible scratches, from turning into a full-fledged crack.

Perhaps more importantly from a business standpoint, it would seem that the process of making sapphire is cost prohibitive compared to Gorilla or other glasses that can be made in a rapid continuous process. I’ve written before about some of the most advanced processes, but making sapphire still requires pulling single boules of crystal, inspecting the boules, sectioning the boule into “good” and bad sections (the diamond wire saws create more waste). After that, one must polish each sheet, a process that can introduce flaws. Critics also say that sapphire will have to be considerably thicker and heavier than GG2 or GG3 and may have glare problems. The video below, although apparently meant to be laudatory, illustrates most of these drawbacks, and the processes stands in sharp contrast to Corning’s continuous and highly automated method for making GG.

Credit: PocketNow; YouTube

Corning is hardly unbiased, but it recently publicly expressed its doubts about sapphire. Although sapphire supporters probably see a victory in the fact that Corning has responded at all, a new press release describes sapphire as “not a major threat.” A company VP, Jeffrey Evenson, says, “What would people say if someone invented a cover that was about half the weight, used 99 percent less energy to make, provided brighter displays, and cost less than a tenth of sapphire? I think they’d say that sapphire was in real trouble. It so happens that we at Corning already invented that cover—and it’s called Gorilla Glass.”

GT, however, seems serious about promoting the idea of using sapphire in consumer touch screens. This week, the company is doing additional demonstrations and presentations at the 2013 Society for Information Display’s Display Week event in Vancouver, B.C.

In news release about appearing at the SID meeting, GT counters doubters, saying, “The presentations will highlight results of recent sapphire material testing and provide an update on the progress being made in the development of an optimized fabrication value chain for delivering low-cost and high volume sapphire screen material. GT is developing and investing in a number of innovative technologies that, when commercialized, will help to lower the cost of sapphire cover screens to levels that are competitive with reinforced glass material.”

GT also has been buying up some manufactures of advanced sapphire-making equipment. For example, last week it announced that it had purchased the Santa Rosa, Calif.-based Thermal Technologies. Tom Gutierrez, GT’s president and CEO says, “The acquisition of the Thermal Technology business adds a number of innovative and important products and technologies to our rapidly diversifying portfolio that will, we believe, allow us to accelerate our entrance into new markets.” Likewise, GT has been announcing some sales agreements with purchasers of crystal-making equipment.

All of this begs the question, Is GT’s business plan to make and sell sapphire touch screens or generate interest in sapphire among touch screen makers in order sell them sapphire-making equipment? I suspect it is the latter. I tried to get clarification on this and many other questions from GT but as of this writing, I have not heard back from the company.

Meanwhile, I am definitely in the cynic category. It’s not just about the inherent weaknesses of sapphire in this type of application. To be successful, you have to have both superior technology and the capability to deliver the product in large volumes at competitive prices. There is uncertainty about the former, and GT cannot do the latter. It is worth remembering that Steve Jobs’ biggest concern about Gorilla Glass wasn’t the technology—it was whether Corning could deliver it in the amounts that Apple thought it could sell, and even then, Corning had to basically drop everything to get the orders filled.

CTT Categories

- Basic Science

- Electronics

- Glass

- Manufacturing

- Optics