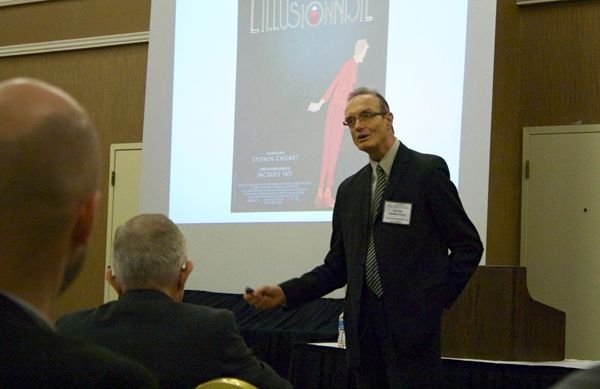

[Image above] Victor Pandolfelli, professor at Federal University of Sao Carlos, Brazil, this year’s T.J. Planje St. Louis Refractories award recipient, challenges attendees to reimagine the “magic” of refractories. Credit: ACerS

Severe thunderstorms rolled into St. Louis, Mo., this week, just as ACerS St. Louis Section and the Refractory Ceramics Division convened for their 51st Annual Symposium on Refractories.

But hail, high winds, thunder, and lightning couldn’t rain on the parade of the 200-plus attendees who, despite the storms, kicked off the meeting with an evening poker run at Ballpark Village St. Louis.

Though this year’s symposium—“Refractories as Engineered Ceramics”—was free of the grand golden celebrations of last year’s event, it offered the same top-notch technical sessions and opportunities for networking. (See the entire technical program here.)

After a welcome from St. Louis Section chair Roger Smith, Bucher Emert Glass, and RCD Chair Ben Markel, Resco Products, Wednesday’s morning technical sessions began with Peter Quirmbach of Deutsches Institut fuer Feuerfest and Keramik (DIFK) and Almuth Sax of University of Koblenz-Landau, Germany, delivering a keynote on forefront measuring techniques for characterizing engineered refractories.

James Hemrick, who recently left Oak Ridge National Laboratory’s High Temperature Materials Lab to join Reno Refractories Inc., tackled one of fellow editor April’s five materials science wonders to watch in 2015—additive manufacturing, and more specifically, that of advanced ceramic components for structural and refractory applications.

We often write about additive manufacturing, but many of the materials being printed are, as Hemrick pointed out, metallic- or polymer-based. Ceramic work is not currently funded due to unproven systems and lack of validation of material quality, he says, but promising work using selective laser sintering and ink-jet printing technologies could eventually change that. He acknowledged the work being done by ACerS member Jennifer Lewis’s research group at Harvard University (see here and here) before detailing the system ORNL is developing to produce optimized simple ceramic materials while reducing crack formation and achieving a finer microstructure. Hemrick also offered 3-D printed props to Local Motors 3-D printed car—the world’s first—and the Shelby Cobra 3-D printed by ORNL.

The balance of the morning session included talks from David Tseng (Alfred University); ACerS Board member and co-program chair Mike Alexander (Riverside Refractories); Duane DeBastiani (Vesuvius Pittsburgh, USA); and Jeremy Watts (Missouri S&T).

Following a spirited lunch where salmon quite literally flew through the air, Victor Pandolfelli, professor at Federal University of Sao Carlos, Brazil, was presented with the T.J. Planje St. Louis Refractories Award. Pandolfelli dedicated his award lecture to former ACerS president, Fellow, and Distinguished Life Member George MacZura, who passed away on March 13, as well as other previous Planje recipients including Dick Bradt and Michel Riguad, to whom he presented the first and second copies of the first volume of the FIRE Compendium Series on Refractory Castable Engineering.

Orville Hunter (left) presents Victor Pandolfelli with the T.J. Planje St. Louis Refractories Award. Credit: ACerS

In his talk, Pandolfelli took on the biggest issue facing industry: How do we attract, inspire, and train the next generation to the field of ceramics and glass—specifically, refractories?

It’s no secret that there are skills and knowledge shortfalls—materials science studies have replaced all but two of the U.S.’s ceramic engineering programs—and yet industry often finds it hard to get rid of old tools that were once quite successful, he noted. What can be done to change the fact we’re so resistant to change?

His analogy of Nokia’s innovation—or lack thereof—provided a clear case study of how resistance to evolve with changing conditions resulted in a loss of market share to the competition (Apple).

Why, then, is the magic of refractories failing to attract and retain the next generation, he asked. Is it too many other professional choices? Not necessarily—but that doesn’t mean it isn’t time to change course.

For the first time in mankind, Pandolfelli observed, there are four, soon to be five, different generations working together. Each has their own view of work and working—none of them wrong, just different. Younger generations are looking for many things, a good working environment, quality of life, and to a surprisingly lesser degree, a good salary. Of utmost importance to these young professionals, however, are challenging tasks.

“If you want challenging things, do refractories,” he says. “What else is more challenging than refractories?”

Perhaps the answer to that question was having to follow Pandolfelli, mused Almatis Inc.’s Dale Zacherl, who joked that the title of his talk, “Castables for industrial applications—Still room for improvement,” implied that it was castables, not the presentation, that left room for improvement.

The post-lunch presentations ended with talks from Carl Zetterström (Kerneos); Bjorn Myhre (Elkem Silicon Materials); and Jessica Rimsza (University of North Texas and ACerS PCSA chair), who provided an update on student and outreach activities, including the PCSA recruitment video the committee debuted recently.

Attendees mingled during a joint tabletop exposition and cocktail hour that drew more than two dozen exhibitors—a warm-up for next month’s inaugural Ceramics Expo (get your free pass to the inaugural trade show here)—and Marcus Fish, development director for The Ceramic and Glass Industry Foundation, was the evening banquet speaker. Fish, who came to Columbus last June to lead fundraising and outreach efforts for the newly formed Foundation, was a fitting bookend for Pandolfelli’s Planje talk earlier in the day, detailing the CGIF’s planned programming and scholarship efforts to attract, inspire, and train the next generation of ceramic and glass professionals.

Thursday’s technical sessions began with the presentation of the 2014 Alfred W. Allen Award. Winners Eric Sako, Mariana Braulio, and Pandolfelli, all of the Federal University of São Carlos, Brazil, and Enno Zinngrebe and Sieger van der Laan with the Ceramics Research Centre, The Netherlands, were honored for their paper “In-depth microstructural evolution analyses of cement-bonded spinel refractory castables: Novel insights regarding spinel and CA6 formation,” published in the Journal of the American Ceramic Society.

RCD Chair Ben Markel (center) with two of the 2014 Alfred W. Allen Award winners, Victor Pandolfelli (left) and Eric Sako (right). Fellow recipients Mariana Braulio, Enno Zinngrebe, and Sieger van der Laan are not pictured. Credit: ACerS

Introduced by Dana Goski, Allied Mineral Products, (who, by the way, was standing in for co-program chair and new dad Matt Lambert) as a “global ambassador for refractory education,” Rigaud, professor emeritus, Ecole Polytechnique, University of Montreal, Canada, echoed the call for education, providing both background and context to the FIRE education programs—“a need for us to survive”—and the Compendium Series’ first volume.

The balance of the morning technical session included talks on refractory castables (a hot topic this year), advanced alumina alternatives, and, of course, Q&A.

I leave St. Louis and you with this—though times are challenging, the people and the companies represented at this year’s symposium seem well-equipped to weather the storms, both now and in a somewhat uncertain future. That being said, it’s never a bad idea to carry an umbrella.

For a full photo recap, click here.

Paul Ormond, Aluchem, Patty Smith, Missouri S&T, and co-program chair Mike Alexander, Riverside Refractories, announce the winner of the kickoff poker run. Allen Davis, Pryor Giggey Co., walked off with top honors and a $500 cash prize. Credit: ACerS

The current and former Planje recipients gather for a group photo. From left: Jim Hill, Michel Rigaud, Howard Johnson, Mark Stett, Charles Semler, Pandolfelli, Dilip Jain, Dick Bradt, Louis Trostel, J.P. Willi, and Kent Weisenstein. Credit: ACerS

Attendees, including Bob Fisher, Duane DeBastiani, and Jeff Smith, catch up during the joint cocktail hour and tabletop expo. Credit: ACerS

Author

Jessica McMathis

Spotlight Categories

- Meeting Highlights

Divisions

- Refractory Ceramics