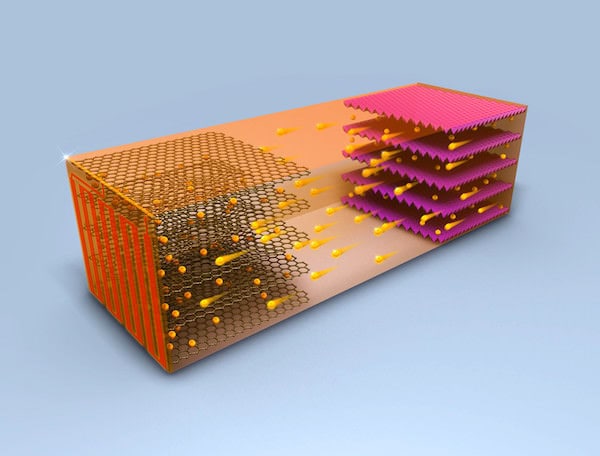

[Image above] Researchers at Penn State have developed a fast-charging battery for all outside temperatures that rapidly heats up internally prior to charging battery materials. Credit: Chao-Yang Wang, Penn State University

A barrier to universal adoption of electric vehicles (EVs) has to do with charging the battery. It can take anywhere from a half hour up to 12 hours, depending on the charging point used and the EV’s battery capacity.

And of course, there needs to be a massive charging infrastructure in place so that drivers will feel confident driving long distances on a single charge.

One factor that significantly impacts EV driving range is the outside temperature. According to the Office of Energy Efficiency & Renewable Energy, cold weather can affect the driving range of plug-in EVs by more than 25%. In a project at Idaho National Laboratory, researchers found that plug-in hybrid electric Chevy Volts driven in winter in Chicago had 29% less range than those driven in spring in Chicago.

It’s common knowledge that batteries, in general, don’t do well in freezing temperatures. But if we’re ever to move beyond gas-powered vehicles, we need a battery that can charge quickly, hold its charge in cold weather, and not cost an arm and a leg.

Researchers at Pennsylvania State University have been thinking about this for a while. A little over two years ago, William E. Diefenderfer Chair of mechanical engineering, professor of chemical engineering, and professor of materials science and engineering and director of the Electrochemical Engine Center, Chao-Yang Wang and his team developed a self-heating lithium battery that uses thin nickel foil with one end attached to the negative terminal and the other end extending outside the battery, creating a third terminal.

The foil serves as a heater of sorts. A temperature sensor sets off electron flow through the foil—heating it up and warming the battery. The sensor switches off after the battery reaches 32oF, allowing electric current to continue flowing normally.

Now, Wang and his team have taken their technology a step further by enabling the battery to charge itself in 15 minutes at temperatures as low as –45oF.

When the battery’s internal temperature reaches room temperature and above, the switch opens to allow electric current to flow in and quickly charge the battery.

“One unique feature of our cell is that it will do the heating and then switch to charging automatically,” Wang explains in a Penn State news release.

He says their battery would not affect the current charging infrastructure. “Also, the stations already out there do not have to be changed,” he adds. “Control of heating and charging is within the battery, not the chargers.”

According to the researchers, charging a lithium-ion battery quickly at temperatures under 50 degrees contributes to its degradation and lithium plating—which can make a battery unsafe. Long, slow charging at 50oF, they say, can avoid lithium plating.

And Wang says their technology can work for other batteries as well.

“The self-heating battery structure is also essential for all solid-state ceramic batteries because it thermally stimulates uniform lithium deposition at the lithium metal anode and compensates for insufficient ionic conductivity of ceramic or glass electrolytes,” he explains in an email. “Plus, solid-state batteries are inherently safe and more efficient to operate at high temperatures. Indeed, a solid state battery would be much inferior without the self-heating battery structure.”

He also says their technology is “pretty mature and readily commercialized by auto OEMs and battery manufacturers.”

That’s good news for those of us who have been hesitant to trade in our gas-powered vehicles for electric ones.

The paper, published in Proceedings of the National Academy of Sciences of the United States of America, is “Fast charging of lithium-ion batteries at all temperatures” (DOI: 10.1073/pnas.1807115115).

Did you find this article interesting? Subscribe to the Ceramic Tech Today newsletter to continue to read more articles about the latest news in the ceramic and glass industry! Visit this link to get started.

Author

Faye Oney

CTT Categories

- Basic Science

- Electronics

- Energy

- Environment

- Material Innovations