Real or “false”? Dental prosthetics are getting so good even patients may not be able to tell the difference after a while. Credit: David Shankbone/Wikimedia Commons.

When it comes to crowns, dental professionals—and patients—have several choices, according to this website. Options include precious metals, porcelain fused to metal (PFM), and ceramics, and dental professionals often use different types of crowns depending on aesthetic and other considerations such as the location of the crown in the patient’s mouth.

Ceramic materials used in crowns include yttria-stabilized zirconia and porcelain-veneered ceramics that provide the strength of ceramic with a natural-looking porcelain exterior for aesthetic purposes.

Now dental professionals have access to a new type of ceramic material that might eventually spell the end of PFM crowns, according to this article.

“While PFMs still have plenty of practical applications today, full-contour all-ceramic restorations are clearly where the industry is headed,” the article says. “The human tooth is ‘full-contour,’ after all. Shouldn’t we aspire to make restorations as strong, aesthetic, and natural as possible?”

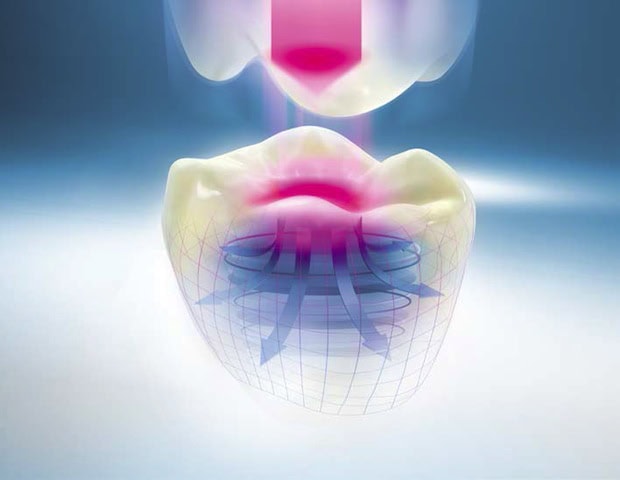

The material taking a bite out of PFM restorative applications is an interpenetrating ceramic composite material being marketed by Vident, Brea, Calif., as Vita Enamic. Seen in the concept photo above (credit: Vident), the material is “the first hybrid dental ceramic in the world with a dual-network structure that combines the best properties of ceramic and composite materials,” according to the company.

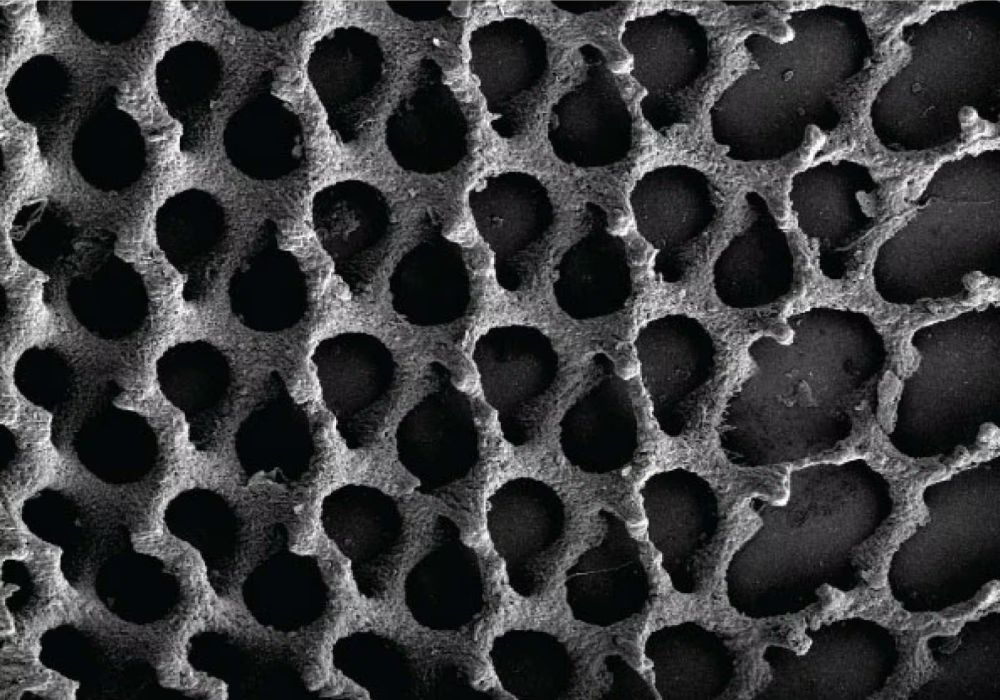

Produced by Vita Zahnfabrik H. Rauter GmbH, Bad Säckingen, Germany, Vita Enamic is a multiphase interpenetrating ceramic composite consisting of 86 wt% ceramic and 14 wt% polymer. The combination provides high fracture toughness, elasticity, and the ability to blunt crack propagation, Vident says. It also machines faster than pure ceramics in the CAD/CAM milling machines used in many dental offices for chairside dental restoration, and reduces wear on the burs used for milling. The product has natural translucency, is available in multiple shades to match patients’ existing teeth, and reduces wear on adjacent teeth compared with pure ceramic crowns, Vident says.

Launched commercially in January, Enamic is the product of roughly two decades of lab work and testing. It was developed by a research team led by Dr. Russell Giordano, a dentist and associate professor in Boston University’s Henry M. Goldman School of Dental Medicine and director of biomaterials. Enamic was developed in the early and mid-1990s and patented in 1996, according to a university news release.

“If you look at a traditional porcelain or traditional ceramic, they may be very strong but they’re still brittle,” Giordano explains in a video interview done at the products introduction ata dental trade show. “If a flaw develops in them, that flaw propagates through the material and causes a fracture. The way this material is designed, if there’s a flaw starting in the material, it goes in between the (ceramic) particles and gets stopped by the polymer or by the interconnected ceramic.”

Details on the proprietary product’s composition and processing are sketchy (OK, nonexistent), but Vident does supply some properties numbers. They include flexural strength of 150–160 MPa, modulus of elasticity of 30 GPa, hardness of 2.5 GPa, and Weibull modulus of 20—more than double that of comparable restorative materials, the company says.

Available in 12 × 14 × 18 mm blocks for CAD/CAM milling, Vita Enamic sold out within weeks of its introduction. Vita says it is still trying to ramp up production capacity to meet demand. For his part, Giordano has continued to work with interpenetrating ceramic composite materials. According to the Boston University news release, he believes the material (or similar materials) may have applications ranging from countertops and tile to body armor.

Author

Jim Destfani

CTT Categories

- Biomaterials & Medical