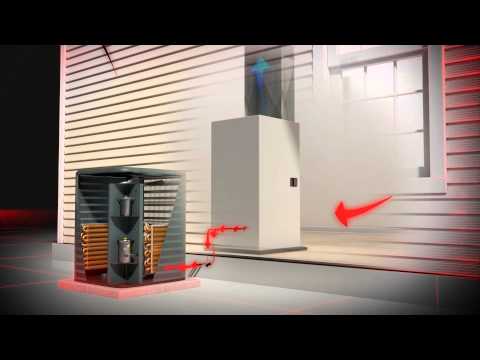

[Image above] Heat pumps are more energy efficient and emit fewer emissions than conventional temperature-control setups that feature a furnace and air conditioner. Researchers are exploring whether solid-state electrocaloric materials could replace the pumps’ internal compressed refrigerant system, thus making heat pumps even more sustainable. Credit: HarmvdB, Pixabay

Even though much of the United States is facing a record-breaking deep freeze this week, many parts of the world are dealing with record-high temperatures instead.

This unseasonably warm weather has scientists already bracing for record-breaking heat later this year that may even beat 2023, which was recently confirmed as the warmest year on record. As a result, demand for air conditioners and other cooling technologies is skyrocketing.

Air conditioning and electric fans currently account for 10% of all global electricity consumption, according to the International Energy Agency. If no action is taken to develop new or improved temperature-control systems, energy demand for space cooling will more than triple by 2050—consuming as much electricity as all of China and India today.

Heat pumps are an old technology that is gaining renewed interest as a sustainable temperature-control system. These devices can both heat and cool a house by transferring heat through a compressed refrigerant system (see video below). Because heat pumps provide the functions of both a furnace and air conditioner, the conventional two-part temperature-control setup, it is more energy efficient.

Credit: Georgia Power, YouTube

Heat pumps are not perfectly sustainable, however, because of their reliance on liquid refrigerants. Their use emits some greenhouse gases, albeit fewer than a combined furnace–air conditioner unit.

Recently, various groups have explored the possibility of replacing the liquid refrigerants in heat pumps with solid-state electrocaloric materials, which undergo a reversible temperature change under an applied external electric field. This property allows for heat transfer without the need for refrigerants or a large, noisy compressor.

Unfortunately, electrocaloric devices to date can only operate within a small temperature span, which prevents their use in real-world environments. But in November 2023, a paper published in Science described a new electrocaloric prototype that operates consistently within a temperature span of more than 20 K, with a cooling power measured up to 4.2 W.

The authors of the Science paper come from Luxembourg Institute of Science and Technology and Murata Manufacturing Co. (Kyoto, Japan). They claim the prototype demonstrates a temperature span and cooling power that are respectively 50% and 15 times larger than those of the previous best electrocaloric device, which they also developed.

The new prototype features a regenerator structure consisting of stacked 0.5-mm-thick multilayer capacitors made from lead scandium tantalate (PbSc0.5Ta0.5O3). The capacitors have spacers positioned on both sides and are electrically connected in parallel, which allows a heat transfer fluid to flow through the device and displace heat accordingly.

The researchers determined the optimal structure to be 10 columns by 14 rows, which achieved a maximum temperature span of 17.4 K at the moderate field of 7.5 V µm−1 (300 V). When they increased the electric field to 10 V µm−1 (400 V), they measured a temperature span of 20.0 K after 4,000 seconds of operation.

With a recovery rate of 99%, the maximum exergy efficiency was 60% with a cooling power of 2.6 W, and 28% at 4.2 W. Alternatively, when the device ran in heating mode, the maximum heating power was 3.1 W, with a temperature span of 4 K.

The prototype also demonstrated excellent durability, with no electrical breakdown or fatigue detected after more than 105 cycles under an applied electric field of 400 V. Furthermore, accelerated lifetime tests on individual multilayer capacitors resulted in an estimated lifetime of 31.7 years under direct current.

In a Science perspective on the study, University of Ljubljana assistant professor of mechanical engineering Jaka Tušek writes, “This high [cooling] efficiency is an important improvement because it finally confirms numerous theoretical studies that predict high efficiency of caloric technologies.”

The authors acknowledge that much work remains before the prototype is ready for real-world application. For example, the electrocaloric device relies on a dielectric fluid rather than water for heat transfer to prevent short circuits. But the dielectric fluid’s poor thermal properties result in longer heat exchange times.

As such, “further improvement is possible by developing waterproof [multilayer capacitors] and by scaling up their number,” the authors write, as well as developing thinner and flatter electrocaloric modules plus applying higher electric fields.

“These obvious improvements would immediately boost performance and are all reasonably attainable goals,” they write.

Notably, this study puts electrocaloric devices near the same playing field as magnetocaloric and elastocaloric devices for the first time.

Like electrocaloric devices, magnetocaloric and elastocaloric devices avoid the use of refrigerants by undergoing reversible temperature changes under applied magnetic or mechanical force fields, respectively. However, researchers have repeatedly reported temperature spans of more than 20 K and cooling powers of more than 50 W for these devices.

On the other hand, electrocaloric devices have great potential for miniaturization and compactness, in contrast to the other devices. This potential makes it a promising technology for microcooling applications.

The paper, published in Science, is “High cooling performance in a double-loop electrocaloric heat pump” (DOI: 10.1126/science.adi5477).

Author

Laurel Sheppard

CTT Categories

- Energy

- Environment

- Material Innovations